Aronia drink and method for producing the same

A technology of aronia and beverages, applied in food ingredients containing natural extracts, food forming, food science, etc., can solve problems such as poor taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

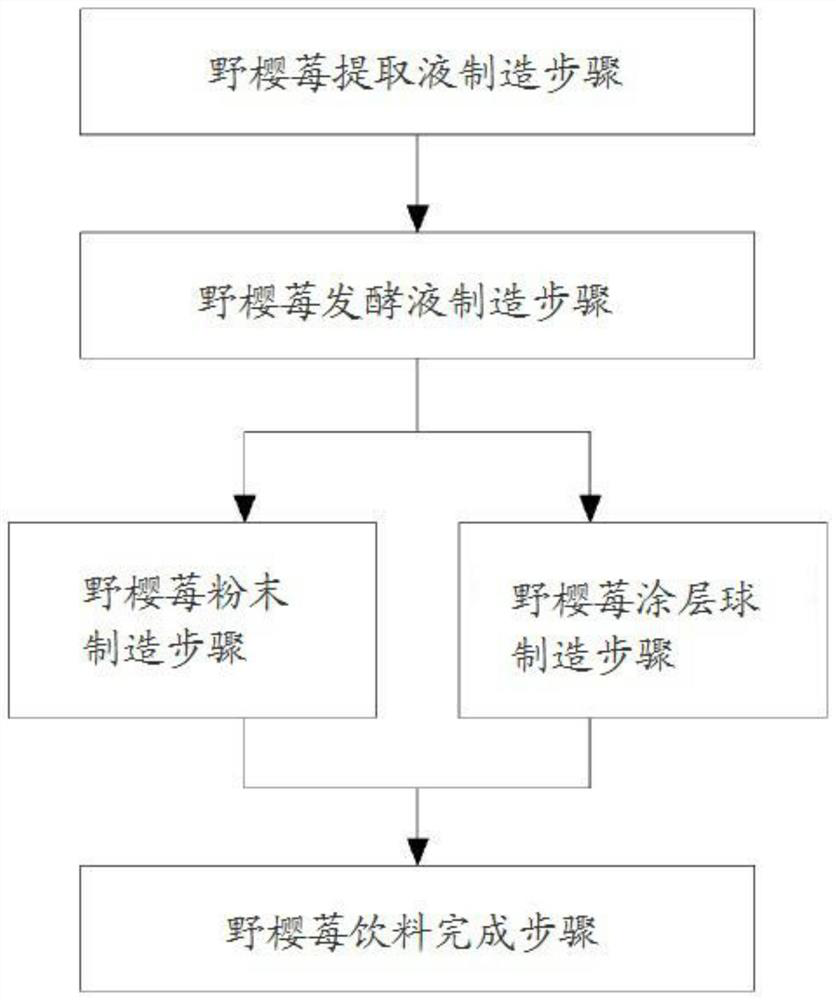

Method used

Image

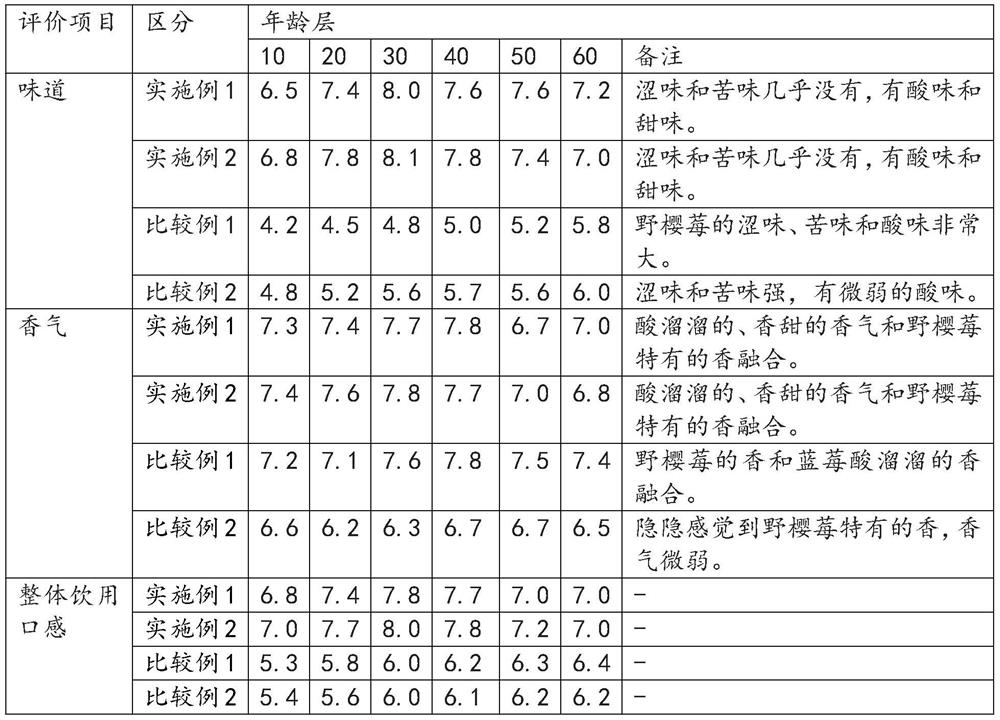

Examples

Embodiment 1

[0034] Crushed aronia berries that have been washed with water are processed to produce crushed aronia berries, and the crushed aronia berries are placed in the inner container of the water bath, and the lids of the inner container and the outer container are closed so that the inside The internal temperature of the container is kept at 85°C for two hours to perform extraction through a water bath, and the steam generated as the water in the external container evaporates flows into the gap between the internal container and the lid while steaming the crushed aronia Processing, extracting and steam-treated aronia crushed material is squeezed into juice with a press machine and sterilized to make aronia extract, mix aronia fruit and sugar in a weight ratio of 1:1, and put Put it into the fermentation container, after 5 months of primary fermentation at 20°C, filter out the slag in the fermentation container, and only re-ferment the liquid part at 20°C for 5 months, so as to make ...

Embodiment 2

[0036] Crushed aronia berries that have been washed with water are processed to produce crushed aronia berries, and the crushed aronia berries are placed in the inner container of the water bath, and the lids of the inner container and the outer container are closed so that the inside The internal temperature of the container is kept at 85°C for two hours to perform extraction through a water bath, and the steam generated as the water in the external container evaporates flows into the gap between the internal container and the lid while steaming the crushed aronia Processing, extracting and steam-treated aronia crushed material is squeezed into juice with a press machine and sterilized to make aronia extract, mix aronia fruit and sugar in a weight ratio of 1:1, and put Put it into the fermentation container, after 5 months of primary fermentation at 20°C, filter out the slag in the fermentation container, and only re-ferment the liquid part at 20°C for 5 months, so as to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com