A test module for a fingerprint sensing device

A technology for testing modules and sensing devices, applied in the directions of measuring devices, measuring device casings, electronic circuit testing, etc., to achieve the effects of improving functional testing, accurate testing, and simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the detailed description presented, various embodiments of systems and methods according to the present invention are described primarily with reference to capacitive fingerprint sensing devices. However, the described invention may also be applicable to other types of fingerprint sensing devices, such as ultrasonic or optical fingerprint sensing devices.

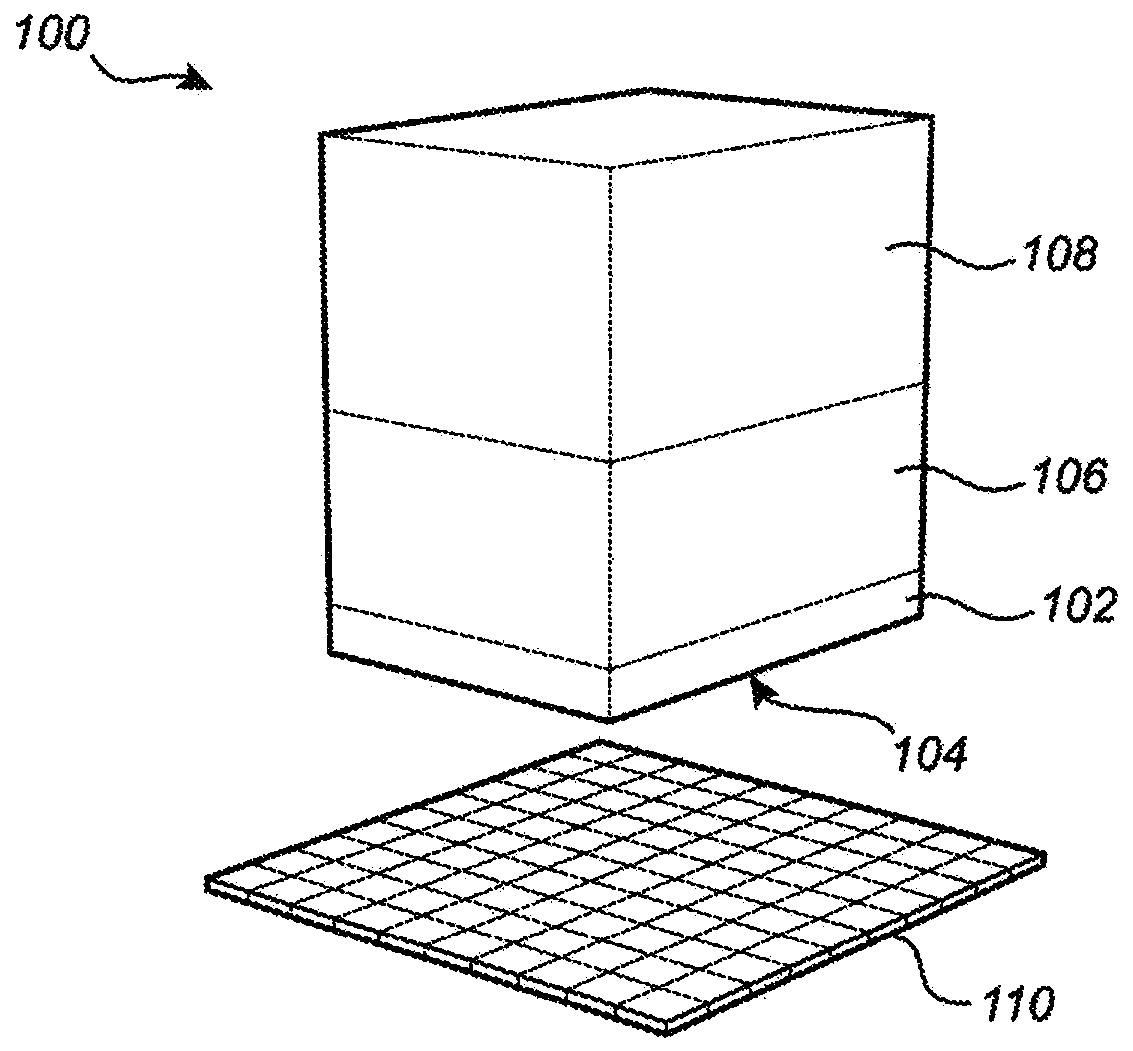

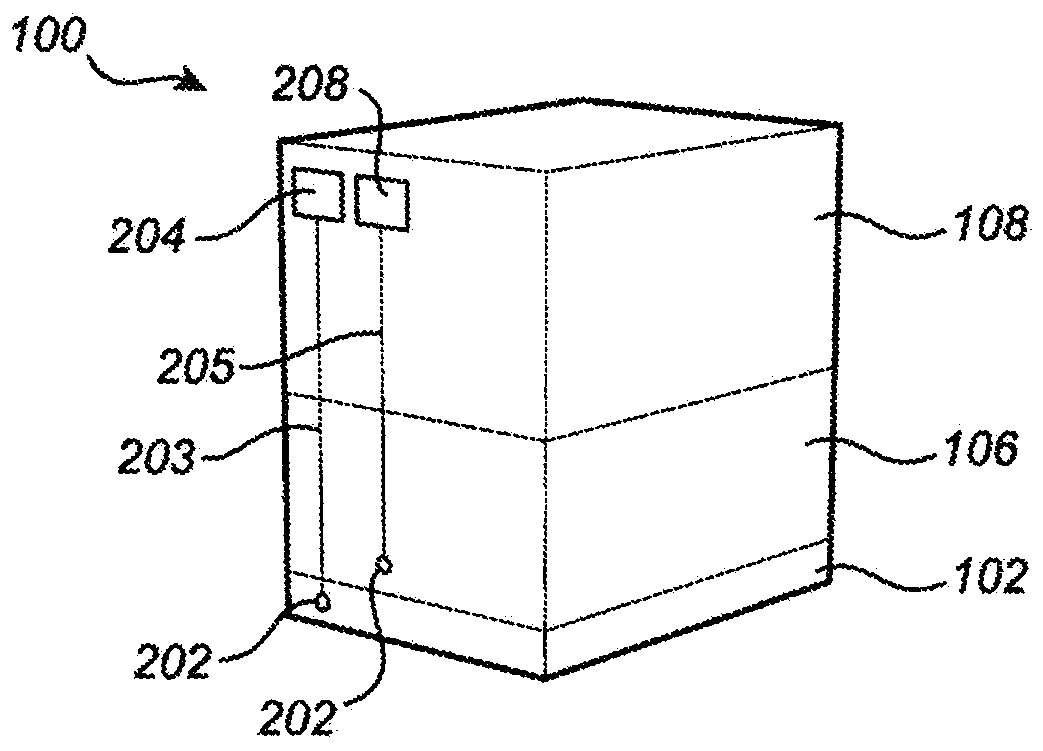

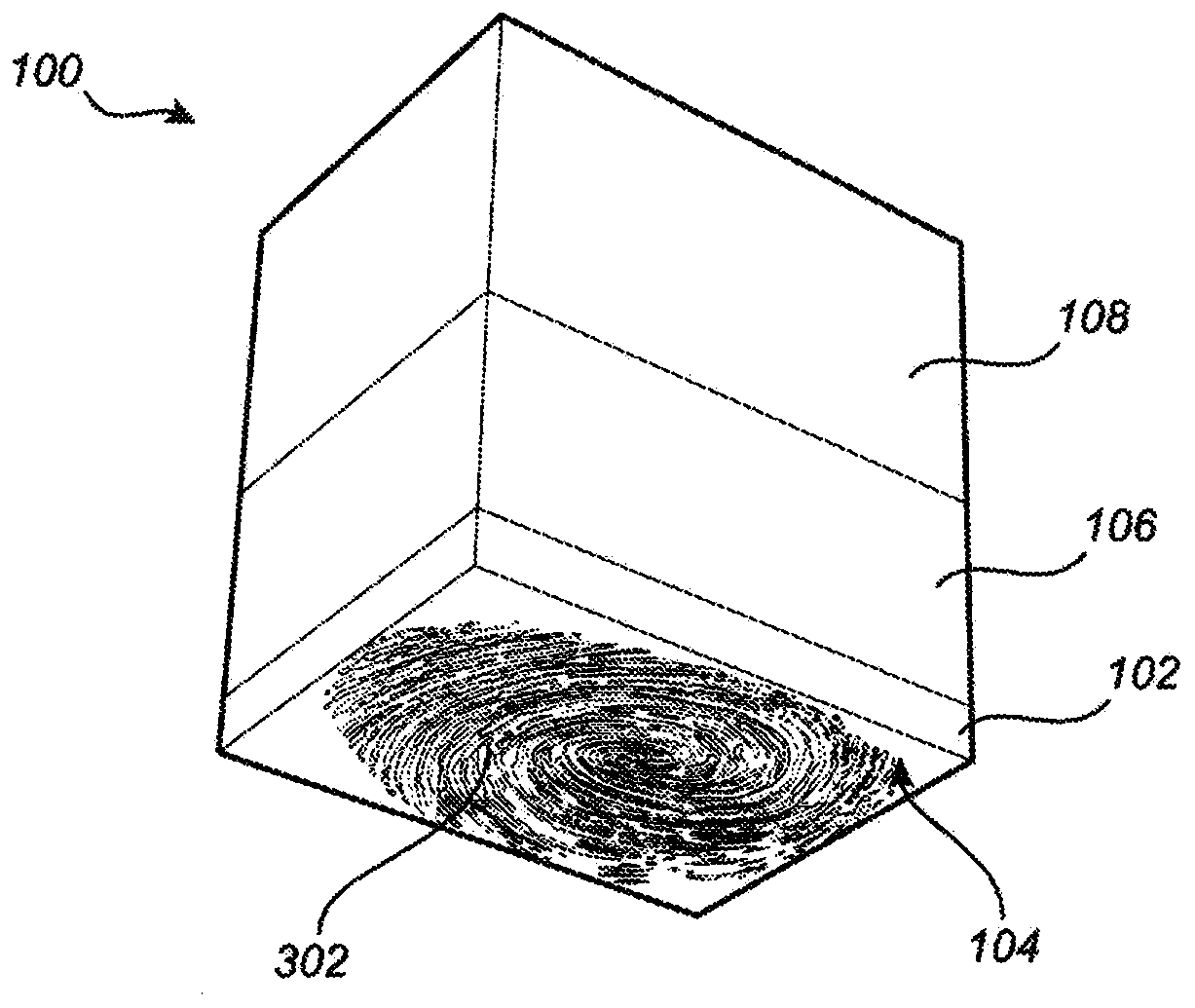

[0039] figure 1 A test module 100 according to an embodiment of the invention is schematically shown. The test module comprises an electrically conductive bottom element 102 comprising an outer surface portion 104 configured to be in contact with a sensing surface of a fingerprint sensing device 110 . The outer surface portion 104 thus refers to the bottom surface of the test module 100 , ie the surface facing the fingerprint sensing device 110 .

[0040] The test module 100 further comprises an electrically conductive intermediate element 106 connected to the bottom element 102 on the side opposite to the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com