Efficient multi-stage sundry removal and leaf selection machine

A leaf sorting machine, high-efficiency technology, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of chaotic distribution of pipelines, difficulty in meeting the technical requirements for the pass rate and purity of tobacco leaves, and affecting the removal effect of compressed air injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in more detail below in conjunction with the embodiments given in the accompanying drawings, but the present invention is not limited to the embodiments.

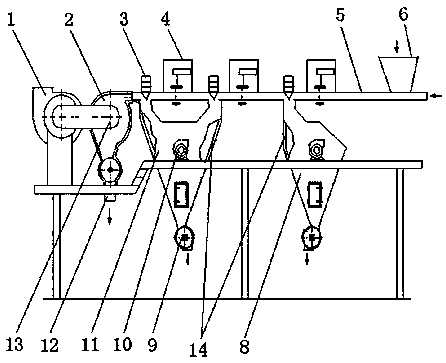

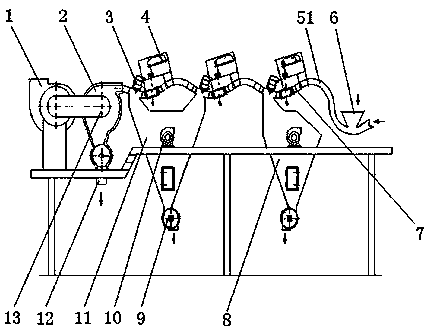

[0015] The high-efficiency multi-stage impurity-removing air leaf separator provided by the present invention includes an air delivery pipeline, an image recognition detector 4, a blower 3, and a collection bin arranged on the air delivery pipeline, wherein:

[0016] Described collection bin is provided with 8 and 11 two, and two collection bins 8,11 all comprise the housing of band cavity, and the housing of collection bin 8 is provided with a material inlet, and this material inlet is connected with the air delivery pipeline. One sundries, secondary smoke outlet of one is connected, and the housing of collecting bin 11 is provided with two material inlets, and two material inlets are communicated with two sundries on the air duct respectively, secondary smoke outlets, each col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com