A climbing anti-skid device for a robot

An anti-skid device and robot technology, applied in the field of robots, can solve problems such as robot damage, low positioning accuracy, and inconvenient driving, and achieve the effects of convenient driving, increased floor space, and beautiful tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

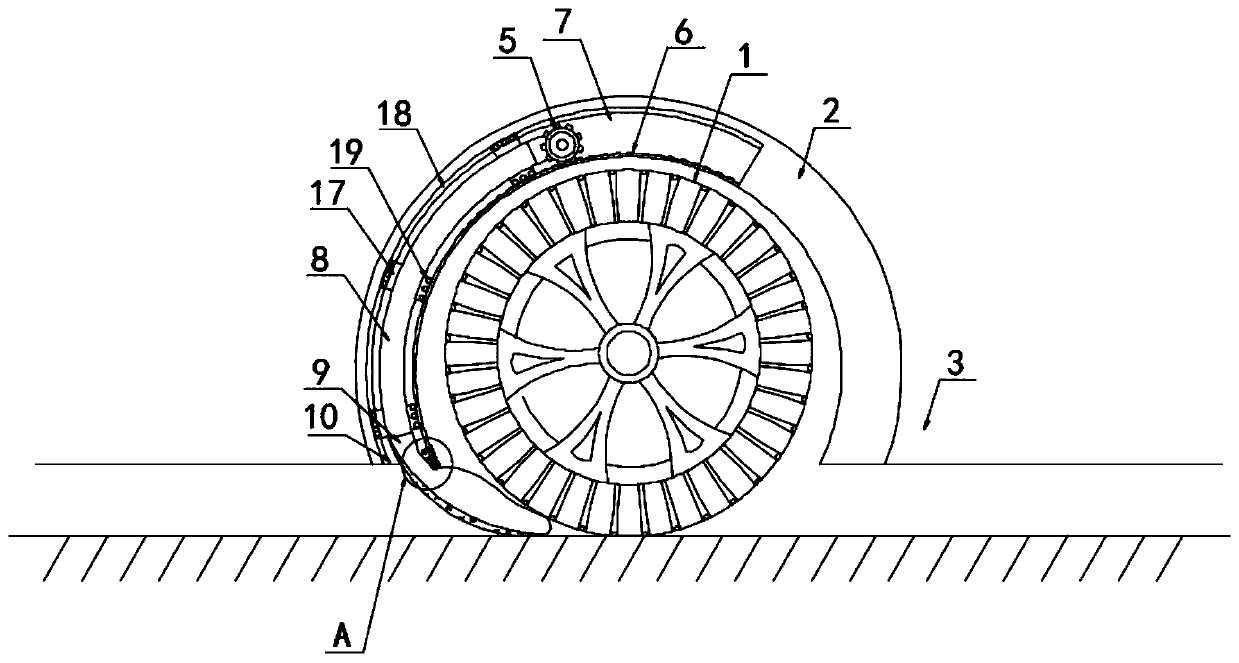

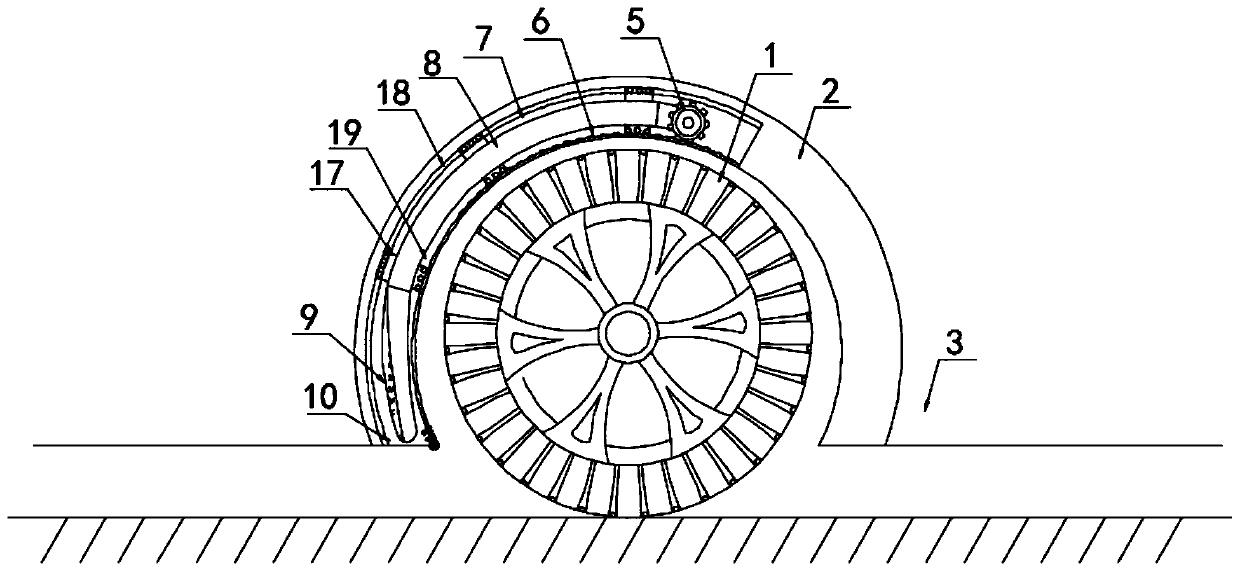

[0031] according to Figure 1-5 A climbing anti-skid device for a robot shown includes a tire body 1 and an anti-dust cover 2, the anti-ash cover 2 is arranged on the top of the tire body 1 and is fixedly connected with the robot body 3, and the inside of the anti-ash cover 2 is provided with Sliding channel 7, the top of the inner cavity of the sliding channel 7 is movable with a biaxial motor 4, and the two ends of the biaxial motor 4 are connected with a moving gear 5 through a rotating shaft, and the bottom surface of the inner cavity of the sliding channel 7 corresponding to the moving gear 5 A gear track 6 is provided, and one side of the biaxial motor 4 is fixedly connected with a connecting slide bar 8 through a bracket, and the bottom end of the connecting slide bar 8 is provided with a movable anti-skid group 9, and the movable anti-skid group 9 includes a bottom friction sand plate 91. Top support anti-skid plate 92, spring damping group 93, outer elastic pad 94 and...

Embodiment 2

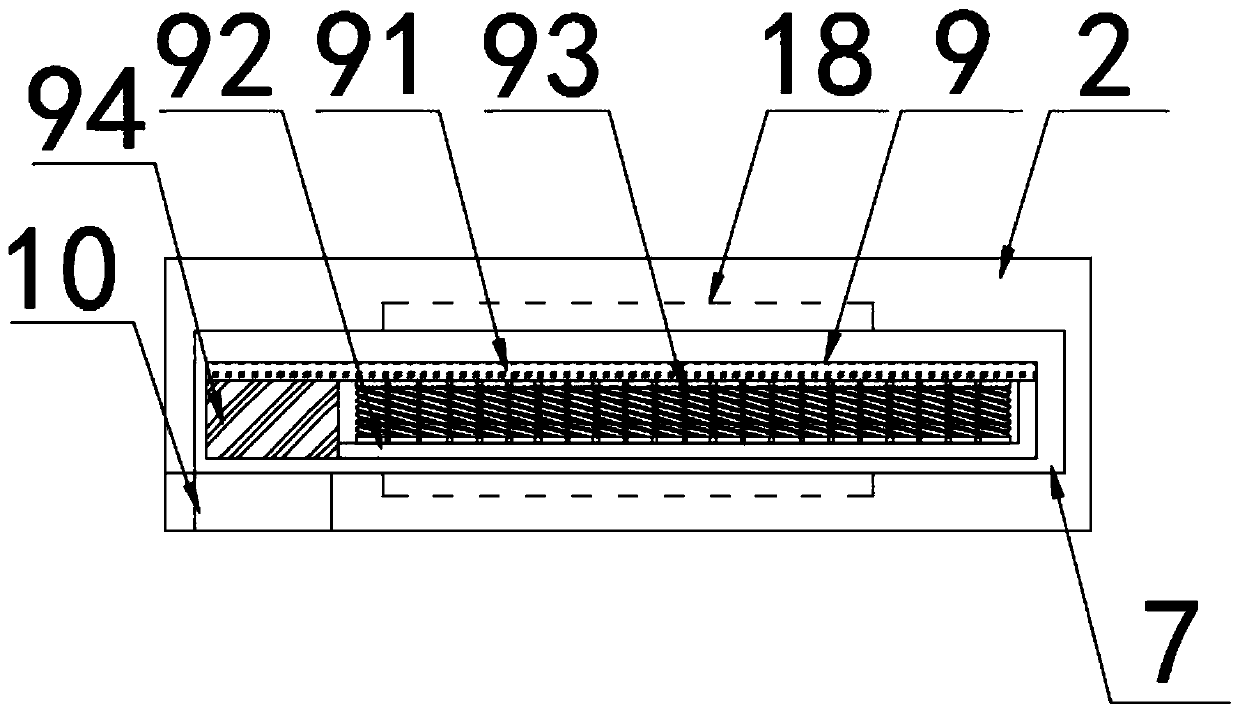

[0036] according to image 3 In the shown anti-slip device for climbing a robot, the spring damping group 93 is composed of springs in a rectangular array, and two adjacent springs are inserted into each other, and are fixedly connected by straps, so that the spring damping group 93 can be stretched arbitrarily, and the service life is extended;

[0037] according to Figure 4 As shown in a climbing anti-slip device for a robot, the cross-section of the connecting clamp 95 is set to an inverted T shape, and the bottom end surface of the connecting slide bar 8 is provided with a slot 14, and the connecting clamp 95 is aligned with the slot 14. Cooperate, be used for being able to disassemble and replace movable anti-skid group 9, when bottom friction sand plate 91 and top support anti-skid plate 92 are damaged or have no friction effect, it is convenient to disassemble and replace. A slot 15 is provided, and a screw is provided in the slot 15, and the screw runs through the c...

Embodiment 3

[0044] according to Figure 8 In the climbing anti-skid device for a robot shown, a solar panel 22 is provided on the outer wall surface of the tire body 1 corresponding to the outer side of the anti-ash cover 2, and a solar controller and a battery are provided inside the anti-ash cover 2 far away from the sliding channel 7. It is used to convert solar energy into electric energy and store it in the storage battery for use by the biaxial motor 4, and is used on outdoor robots, which is green and environmentally friendly.

[0045] The working principle of the present invention:

[0046] Refer to the attached figure 1 with Figure 4-5 , when in use, by utilizing the anti-ash cover 2 that will be provided on the top of the tire body 1 to open a sliding channel 7 for placing the movable anti-skid group 9 connected with the biaxial motor 4 transmission, when the robot climbs a slope, if the speed is too low or When it is necessary to stop working on a slope, the robot controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com