Small triangular crawler chassis applicable to hilly and mountainous regions

A crawler chassis and triangular technology, applied to tracked vehicles, non-deflectable wheel steering, steering mechanisms, etc., can solve the problems of incomplete consumption of vibration and impact, high center of gravity, prone to rollover, etc., to reduce vibration impact and fatigue, reduce the shortened life of parts, and improve driving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

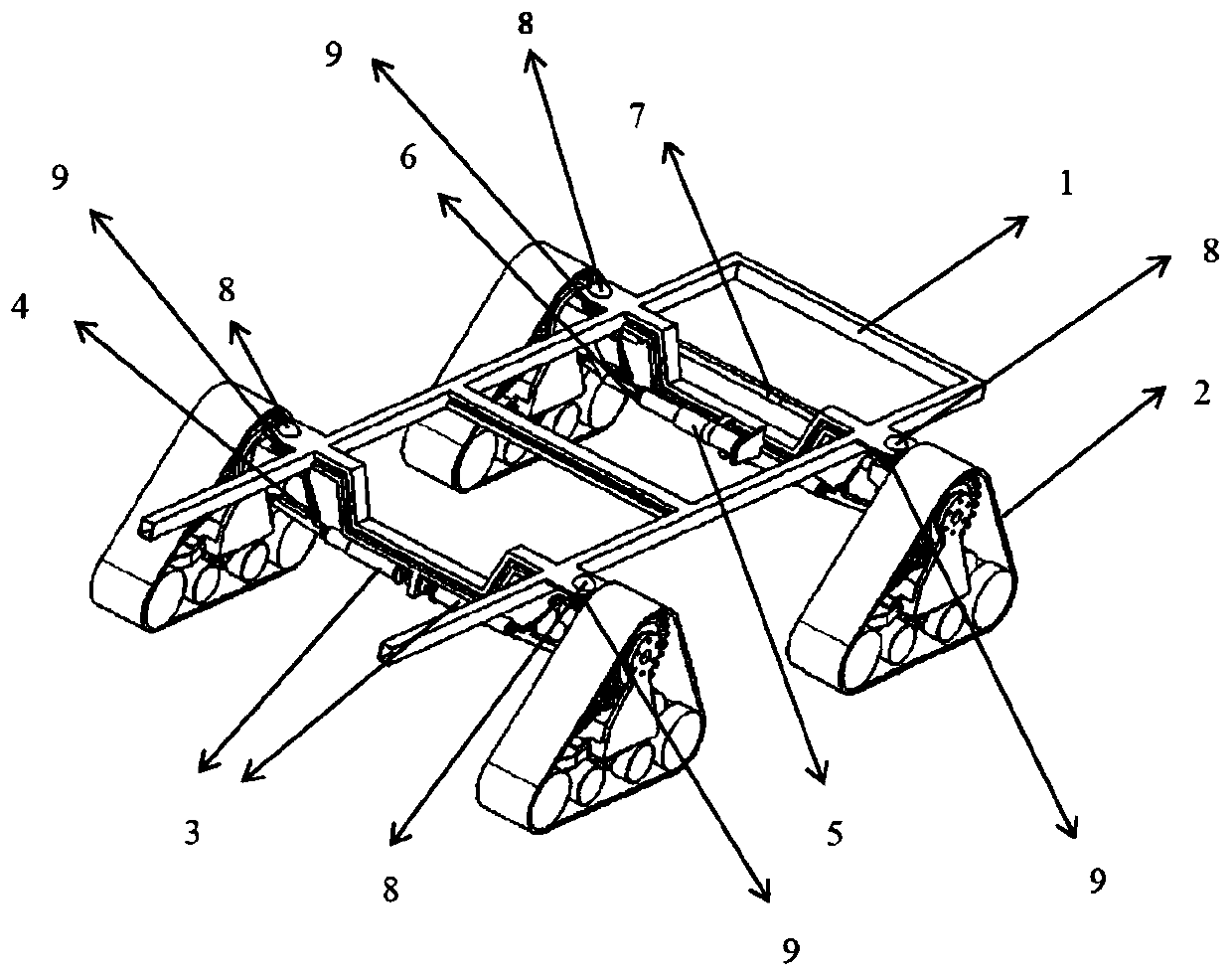

[0032] A small triangular crawler chassis suitable for hilly and mountainous areas, including a frame, a triangular crawler wheel traveling mechanism, a lifting mechanism and a steering mechanism.

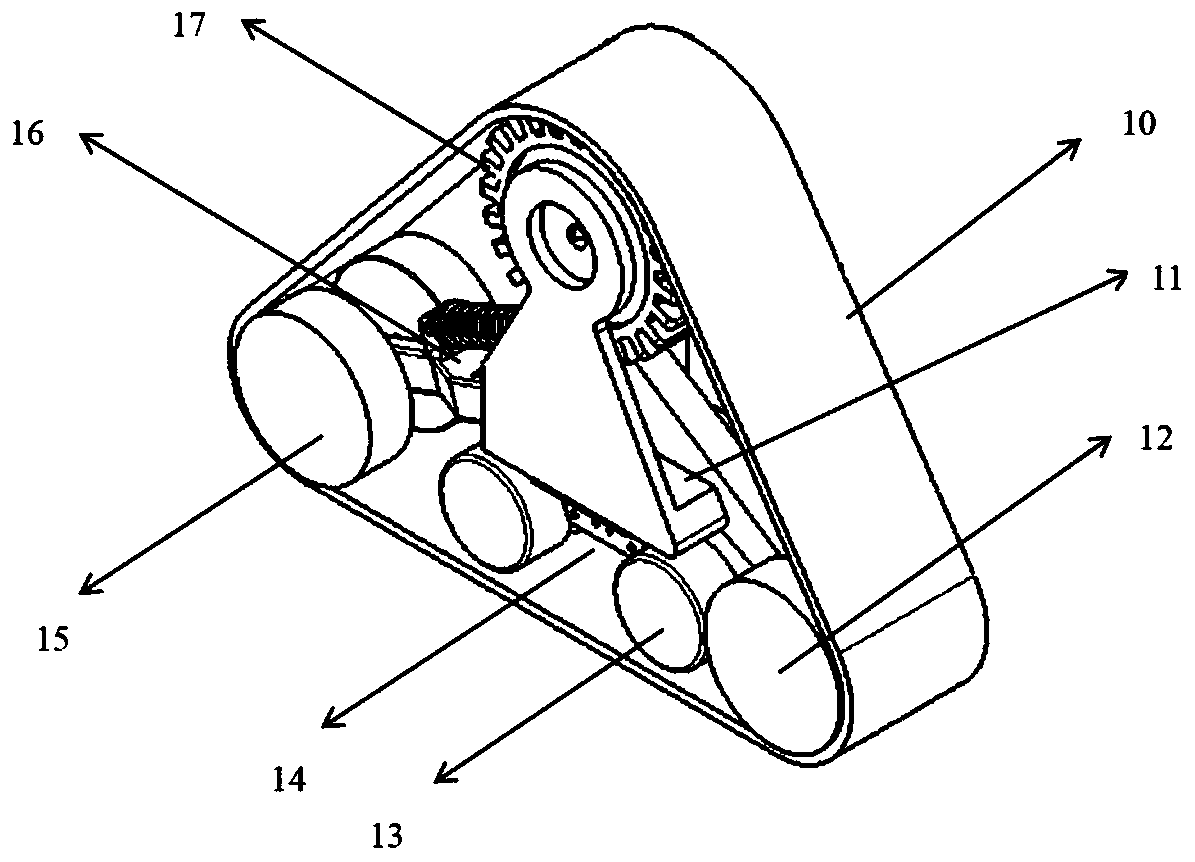

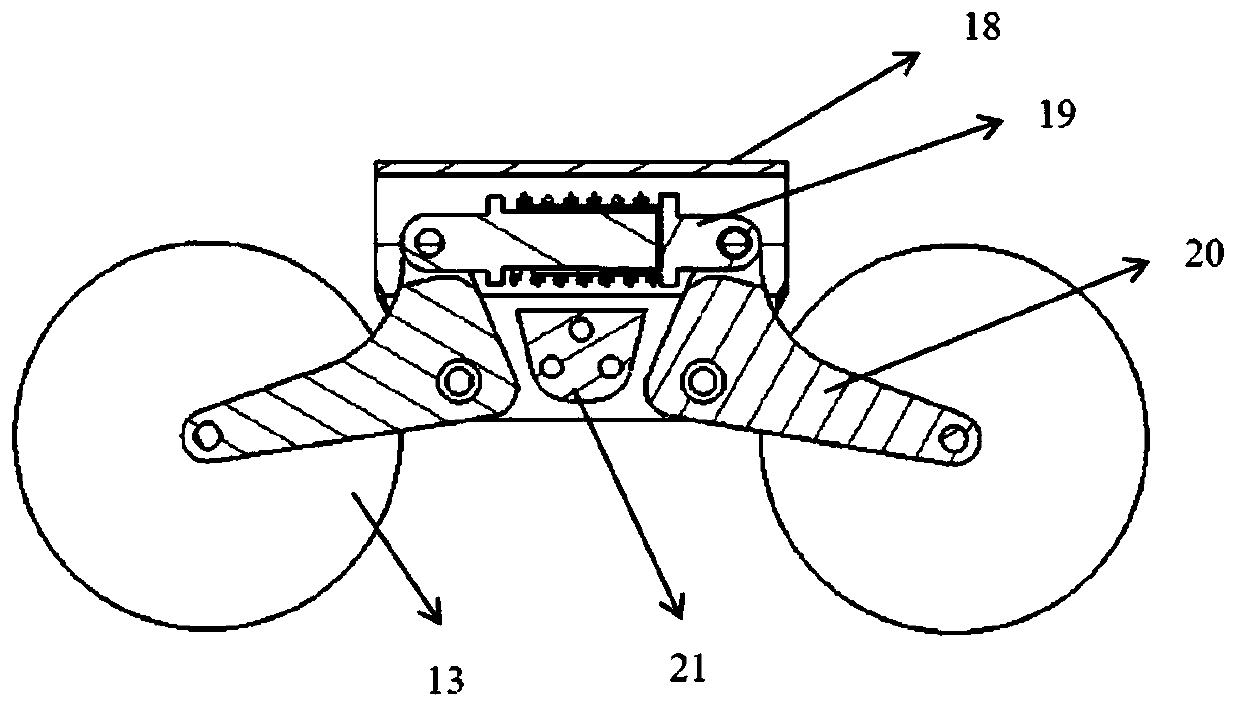

[0033] The triangular crawler wheel traveling mechanism includes a crawler belt, a driving wheel, a guide wheel, a tensioning device, a load damping device and a support. The tensioning device includes a tensioning wheel, a shock absorber II, a swing arm, a damping spring II, a rotating pin and a fixing nut; Nut connection, the swing arm is a fork structure (similar to Y shape), one end of the swing arm is hinged with the bracket, the other end is connected with the tension wheel, and the middle part is connected with the shock absorber II and the shock absorber spring II. Lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com