Silver film etchant composition, etching method using same, and metal pattern forming method

A technology of composition and etching solution, which is applied in the direction of surface etching composition, chemical instrument and method, electric solid device, etc., can solve the problems of wiring floating or peeling, poor wiring side profile, and no etching solution composition has been proposed , achieve the effect of reducing side etching and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7 and comparative example 1 to 3

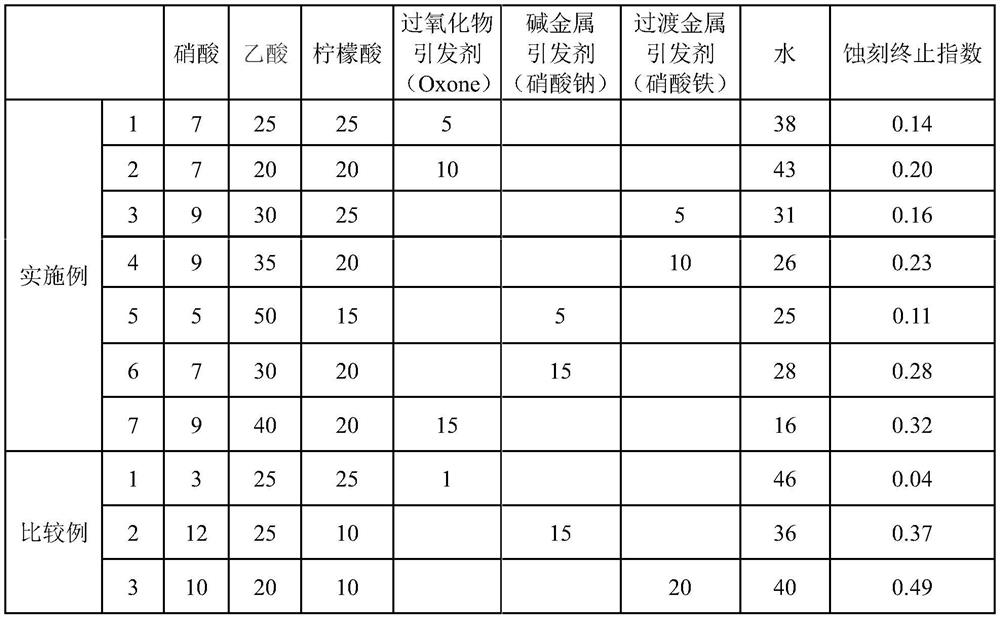

[0061] Silver film etching liquid composition is prepared by incorporating the content described in Table 1 below. The etch stop refers to an etch stop phenomenon that does not further etch when the condition of the etching composition is changed, and the side etching can be predicted before the SEM (scanning electron microscope) is measured. Values do not increase the parameters.

[0062] The etching termination index of the present invention is (inorganic acid + initiator) / (organic acid + water), the etching termination index is preferably 0.05 to 0.35, and the etching end index is for speeding an etching ratio and an inorganic acid and an etch rate. The content of the initiator relative to the ratio of the ratio of the organic acid used to chelate the metal can be predicted in advance, whether the S / E is increased.

[0063] [Table 1]

[0064] (unit weight%)

[0065]

experiment example 1

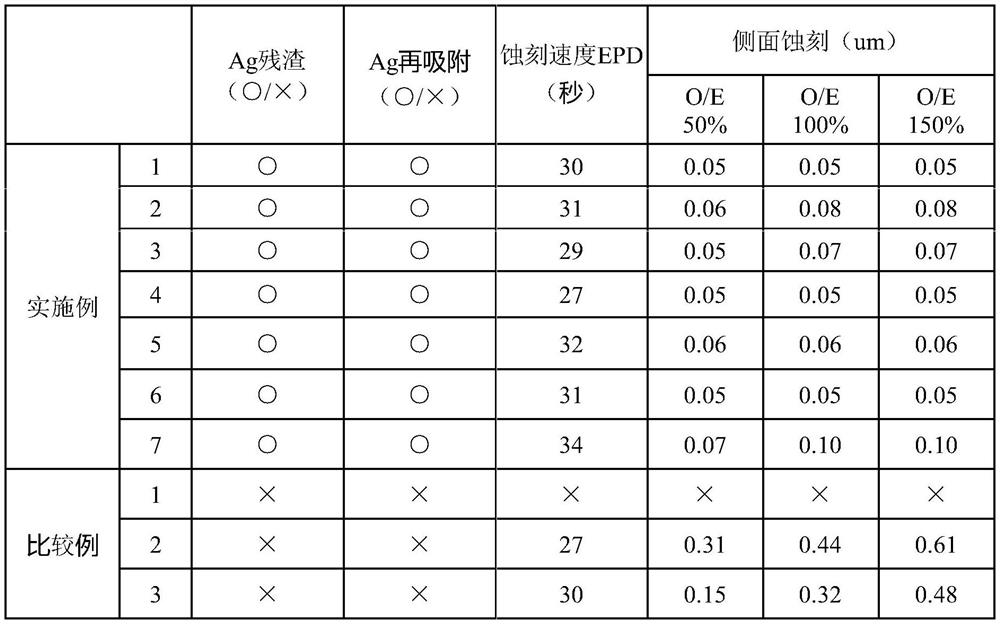

[0066] Experimental example 1. Performance test of silver etching liquid composition

[0067] A ITO / Ag / ITO triple film is formed on the substrate, and an etching process is carried out using an experimental device (model name: ETCHER (TFT), SEMES) of the injection. The silver etching liquid compositions of Examples 1 to 7 and Comparative Examples 1 to 3 described above were added to the experimental apparatus, and the temperature was set to 40 ° C for temperature rise, and then the temperature was performed when the temperature reached 40 ± 0.1 ° C. Etching step of ITO / Ag / ITO triple film. The total etch time is set to 60 seconds. In the experiment, after evaluation using the silver etching liquid composition using the initial time (0 time), the resolution composition was carried out using the same silver etch composition after 12 hours and 24 hours, respectively.

[0068] Silver residue

[0069] The silver etching liquid compositions of Examples 1 to 7 and Comparative Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com