Etchant composition for silver thin layer and ehting method and mehtod for fabrication metal pattern using the same

A technology of composition and etching solution, applied in the direction of surface etching composition, chemical instrument and method, etc., can solve the problems such as etching solution composition that has not been proposed yet, and achieve the effect of excellent etching straightness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 11 and comparative example 1 to 12

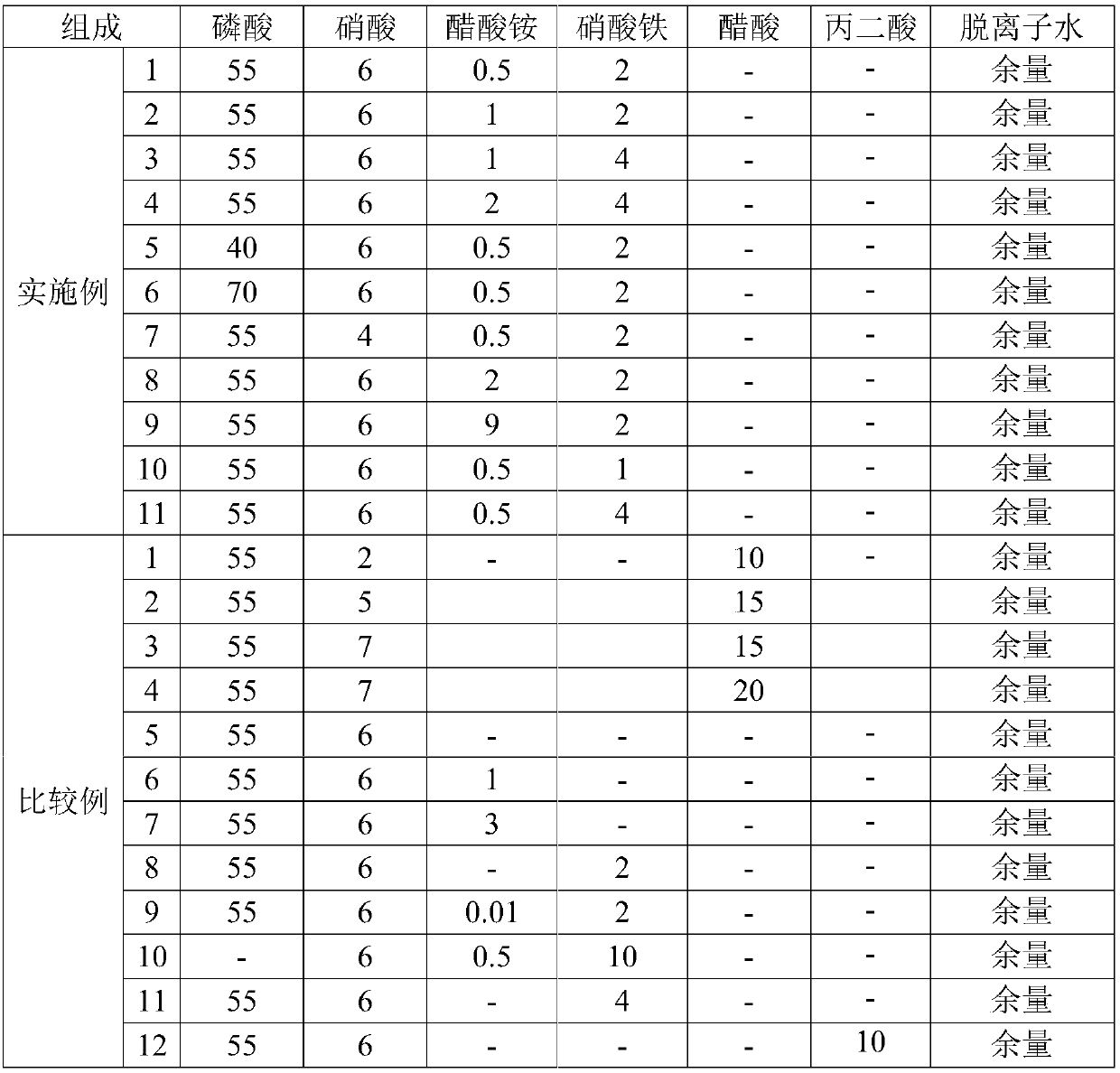

[0062] A silver etchant composition was prepared by mixing the corresponding components at the contents described in Table 1 below.

[0063] [Table 1]

[0064] (unit weight%)

[0065]

experiment example 1

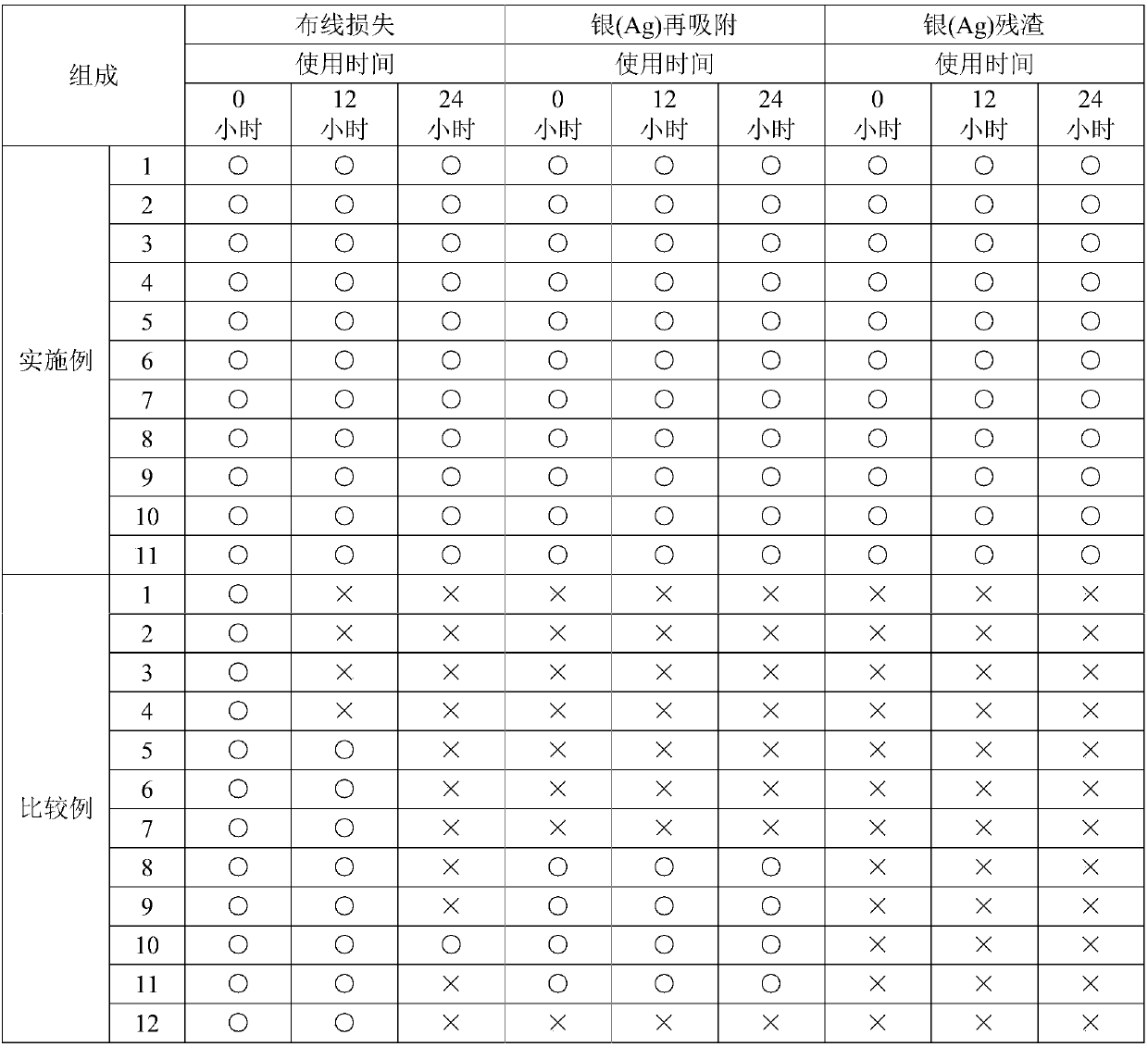

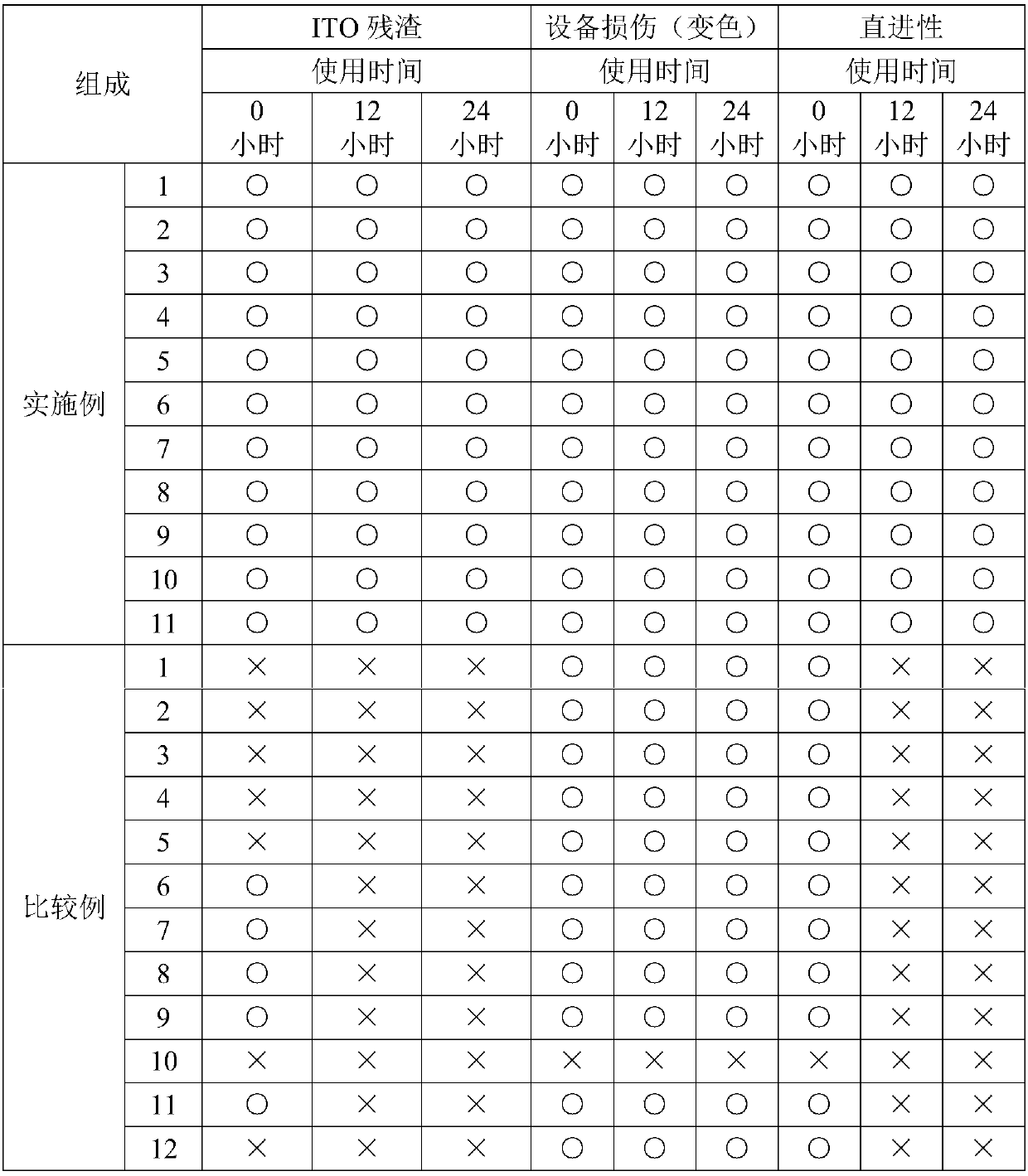

[0066] Experimental example 1. The performance test of silver etchant composition

[0067] An ITO / Ag / ITO triple film was formed on a substrate, and an etching process was performed using a jet etching experimental device (model name: ETCHER (TFT), SEMES). Add the above-mentioned silver etching solution compositions of Examples 1 to 11 and Comparative Examples 1 to 12 respectively into the experimental equipment, set the temperature to 40°C and then raise the temperature, and then when the temperature reaches 40±0.1°C, perform the above steps. The etching process of the ITO / Ag / ITO triple film is described. The total etching time was set to 60 seconds and implemented. In the experiment, after evaluation was performed with the silver etchant composition used for the initial time (0 time), 12 hours and 24 hours later, re-evaluation was performed with the same silver etching composition.

[0068] 1. Measuring Wiring Loss

[0069] Regarding the loss of the wiring (or reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com