Etching solution composition, wiring, array substrate for display device and manufacturing method thereof

A technology of composition and etching solution, which is applied in the direction of surface etching composition, chemical instruments and methods, instruments, etc., can solve the problems of poor etching straightness and uniformity, and achieve excellent etching straightness and uniform etching excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~15

[0098] Embodiment 1~11 and comparative example 1~15. manufacture of etchant composition

[0099] Etching liquid compositions of Examples 1 to 11 and Comparative Examples 1 to 15 were produced according to the composition and content shown in Table 1 below, and deionized water was included in the balance so that the total weight of the composition became 100% by weight. .

[0100] [Table 1]

[0101] (unit weight%)

[0102]

experiment example 1

[0103] Experimental example 1. Performance evaluation of etching solution composition

[0104] Will be in 100mmX100mm glass (SiO 2 ) on the substrate according to Thickness evaporated Al film, on it according to The substrate on which ITO was vapor-deposited to a thickness was used as a test piece, and a photoresist film was formed on the above-mentioned ITO. Etching was performed at 33° C. using the etching solution compositions of the above Examples and Comparative Examples.

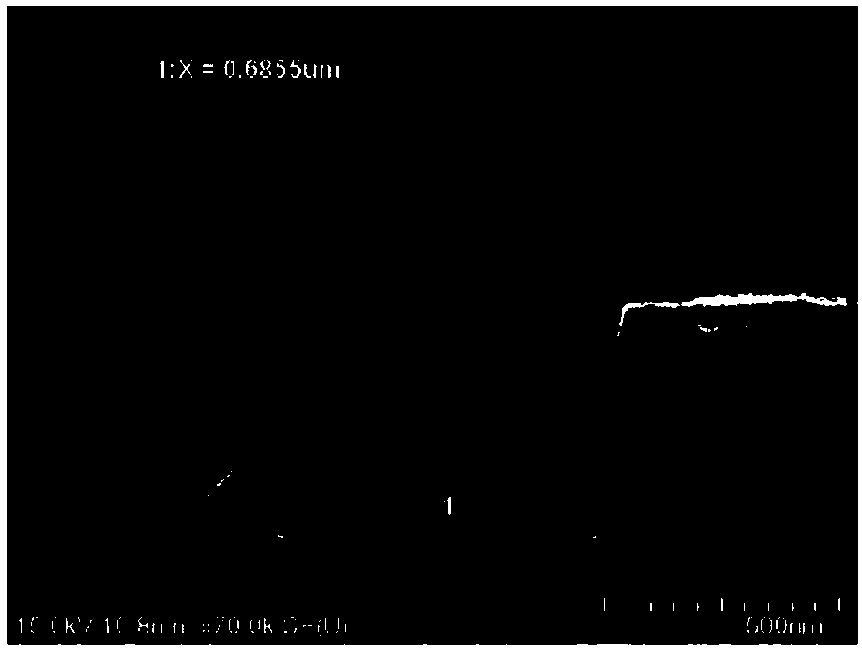

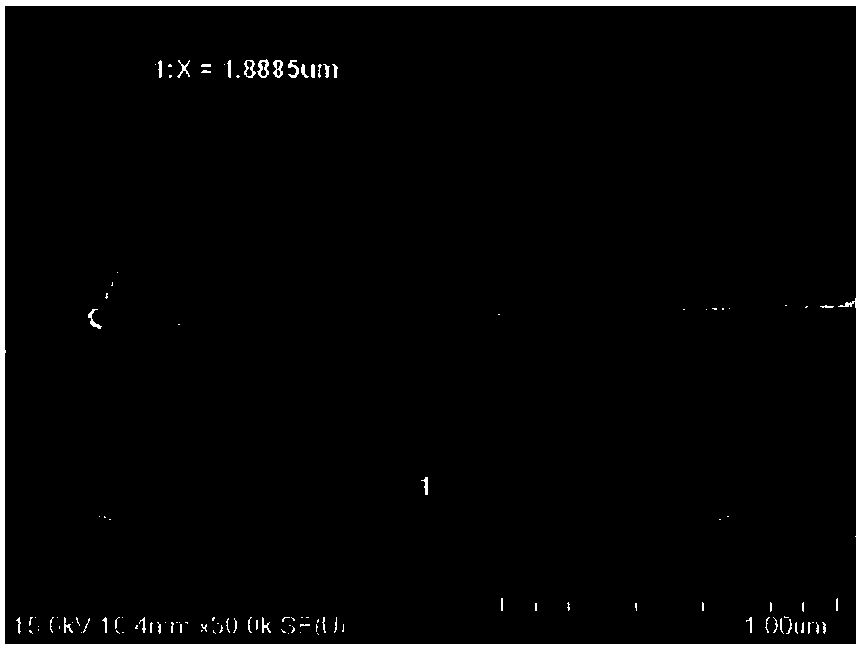

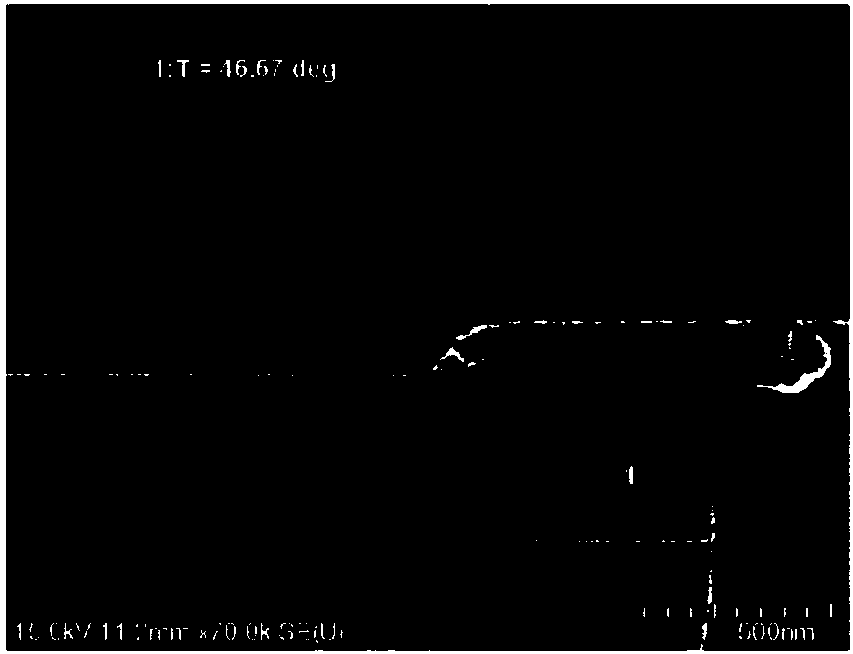

[0105] The etching machine (Etcher) uses a 0.5-generation device that can handle glass size (Glass Size), sprays the etching solution composition at 0.1MPa, and maintains the exhaust pressure in the etching zone (Etching zone) at 20Pa. After etching, use SEM equipment to confirm side etch (side etch, S / E), taper angle (taper angle, T / A), the generation of the upper ITO tip and the damage degree of the lower aluminum film, and the results are shown in the following table 2.

[0106]

[0107] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com