Peristaltic pump head

A peristaltic pump and pump cavity technology, applied in the field of peristaltic pumps, can solve problems such as dripping, poor pressure relief effect, and inability to transport liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

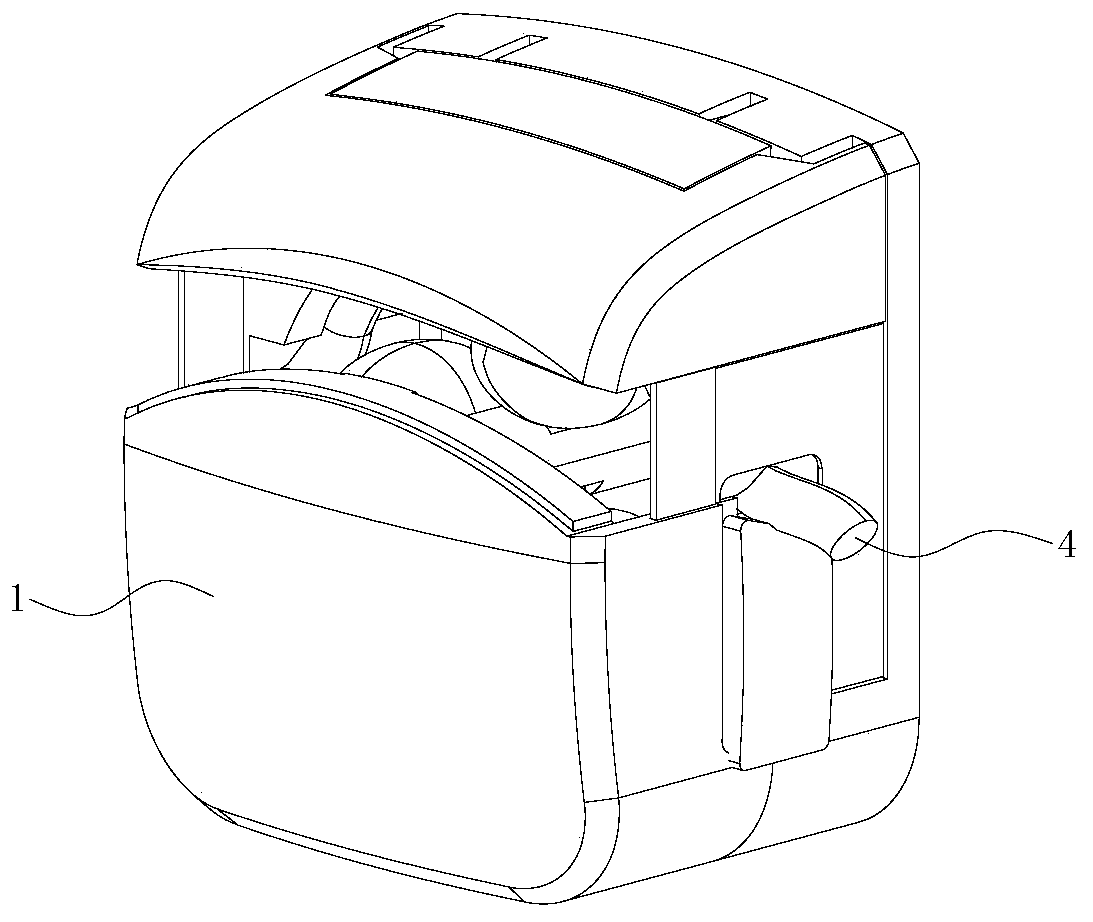

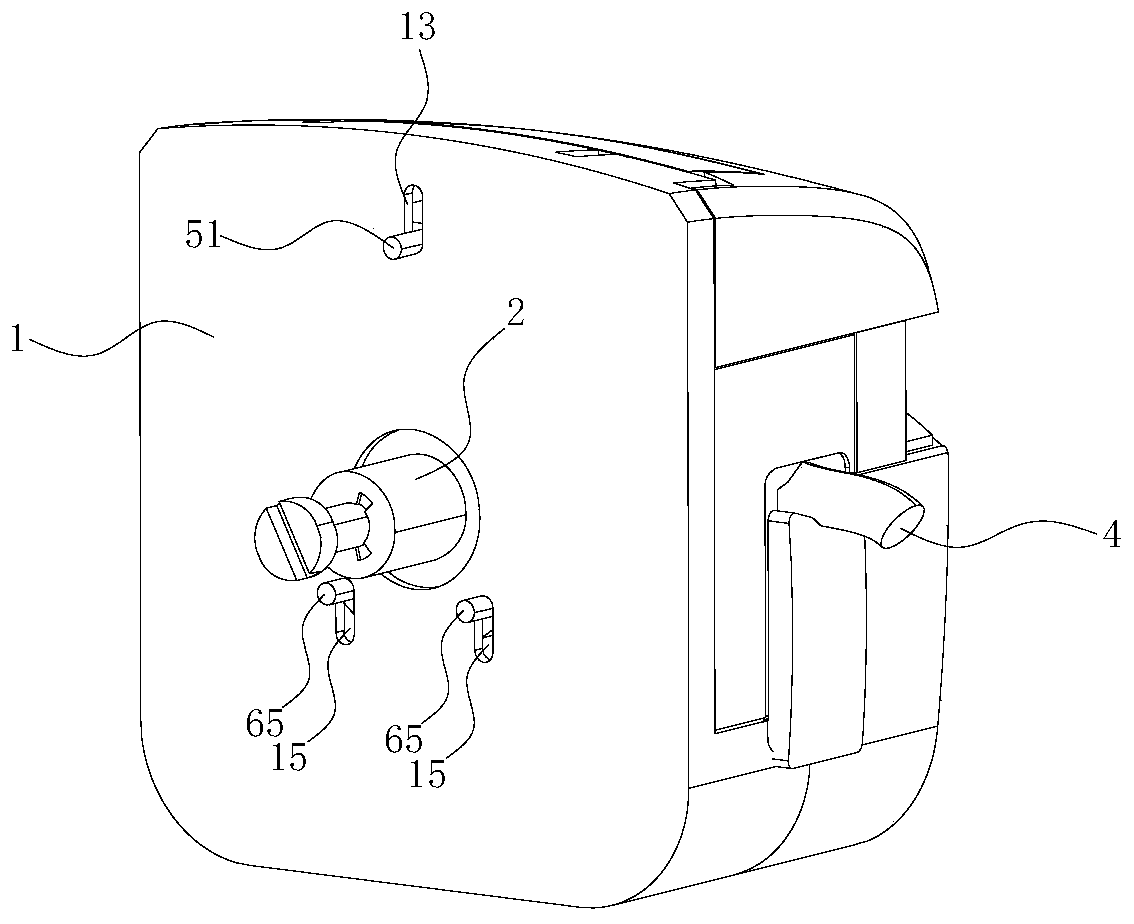

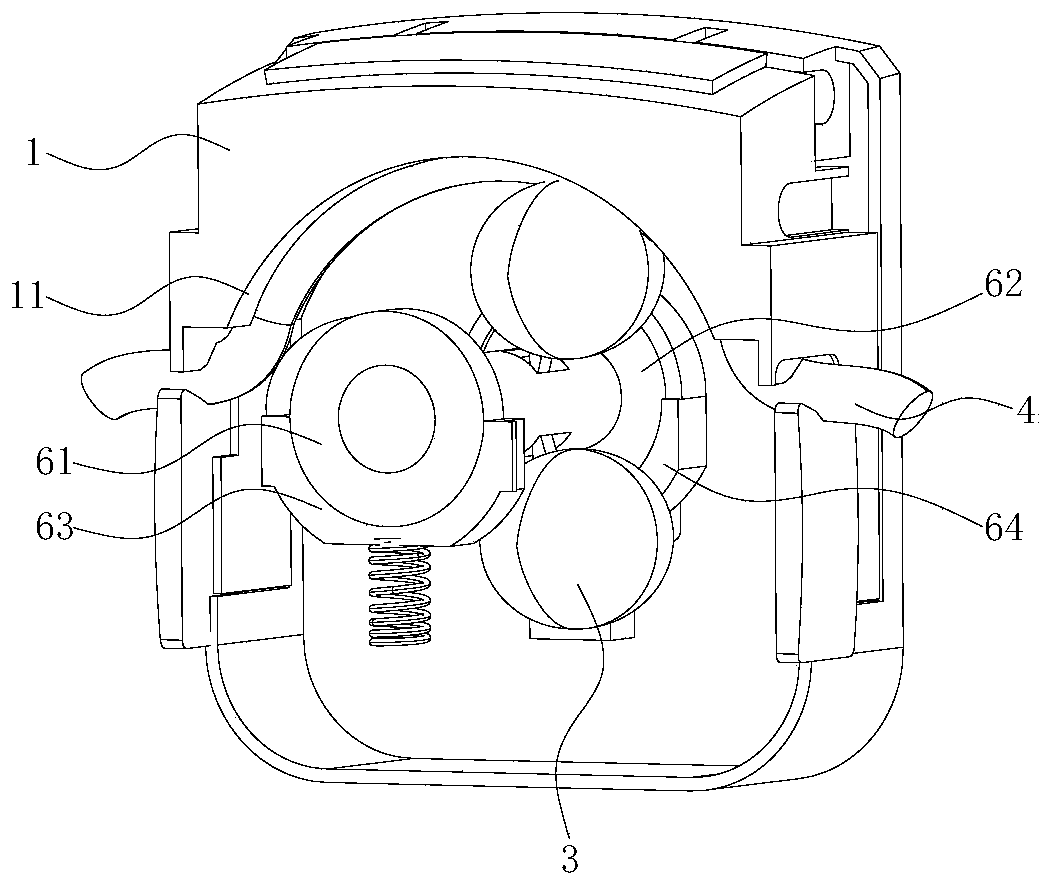

[0046] Such as figure 1 with figure 2 The peristaltic pump head shown includes a pump body 1 with a pump cavity inside and a main shaft 2 passing through the pump cavity along the front and rear directions of the pump body 1, as shown in image 3 with Figure 4 As shown, there are three rollers 3 evenly distributed in the circumferential direction on the main shaft 2, and a clamp hole is provided on the left and right sides of the pump chamber, and the hose 4 penetrates into the pump chamber through one of the clamp holes and then passes through the other clamp hole. out, such as Figure 4 As shown, the top of the pump chamber has a cylindrical surface 11 coaxially arranged with the main shaft 2, and the hose 4 is attached to the cylindrical surface 11 under the action of the roller 3, as Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, there is a concave hole 12 extending radially along the main shaft 2 on the cylindrical surface 11 , a first pressure relief s...

Embodiment 2

[0061] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the concave hole 12 is located directly above the main shaft 2, and a through hole communicating with the outside of the pump body 1 is provided on the top of the concave hole 12. The driving unit is a cylinder with a piston rod fixed on the upper part of the pump body 1. The piston rod of the cylinder passes through the through hole and is fixedly connected with the slide seat 5. When the piston rod of the cylinder shrinks, it drives the slide seat 5 to move upward, so that the hose 4. Pressure relief. In this case, when the piston rod of the cylinder is stretched to the longest, the end surface of the slide seat 5 near the end of the main shaft 2 is higher than the cylindrical surface 11. After the pressure relief is completed, in order to reset the sliding seat 5 in time, a spring against the sliding seat 5 is provided on the top of the concave hole 12 . ...

Embodiment 3

[0063] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the roller 3 is in the shape of a truncated cone and its central axis is parallel to the central axis of the main shaft 2, and the diameter of the roller 3 gradually decreases from front to rear. When the main shaft 2 is in the working state, the largest diameter of the roller 3 is squeezed on the hose 4 . Since the diameter of the roller 3 decreases gradually from front to back, the diameter of its front end is the largest, and the front end of the roller 3 is squeezed on the hose 4 when the main shaft 2 is in working condition. When the pressure needs to be relieved, the driving roller 3 moves from the back to the front.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com