Wire and cable head peeling device

A wire and cable and wire end technology, which is applied in the field of wire and cable end stripping devices, can solve problems such as cutting labor, affecting splicing work, reducing cutting quality and efficiency, and achieving the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

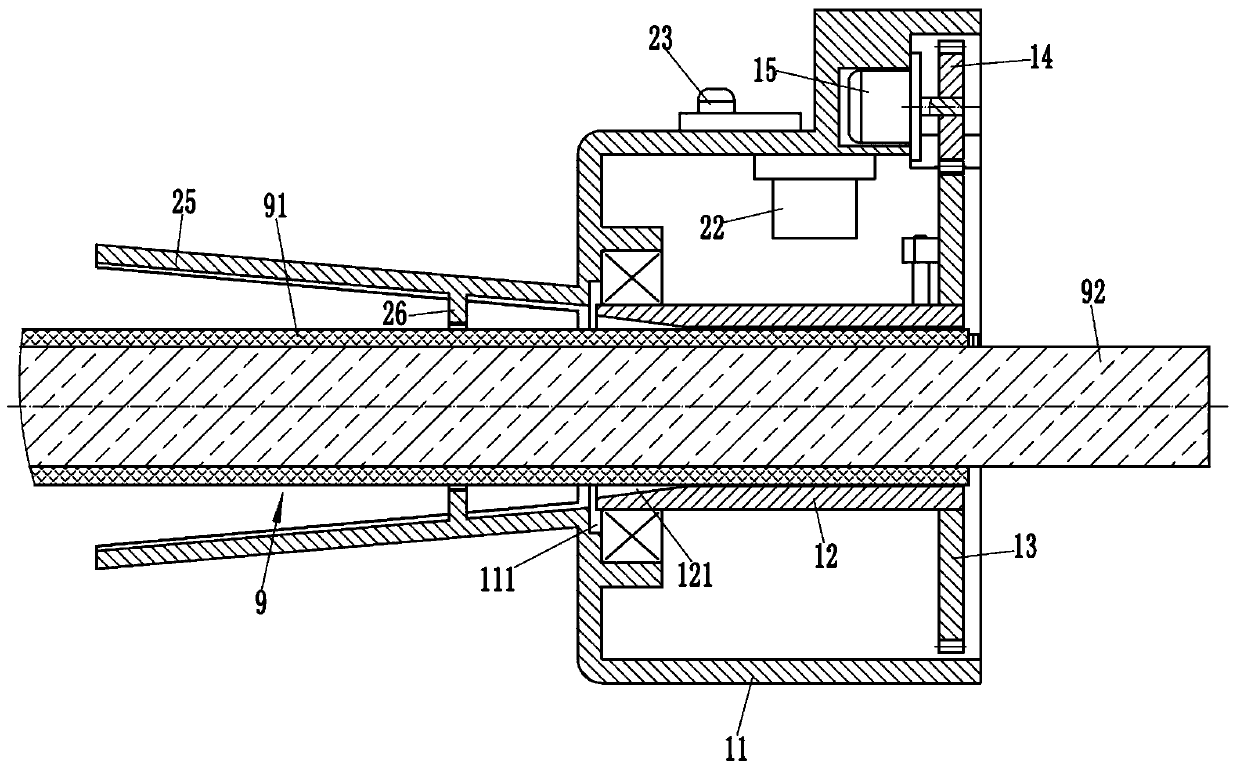

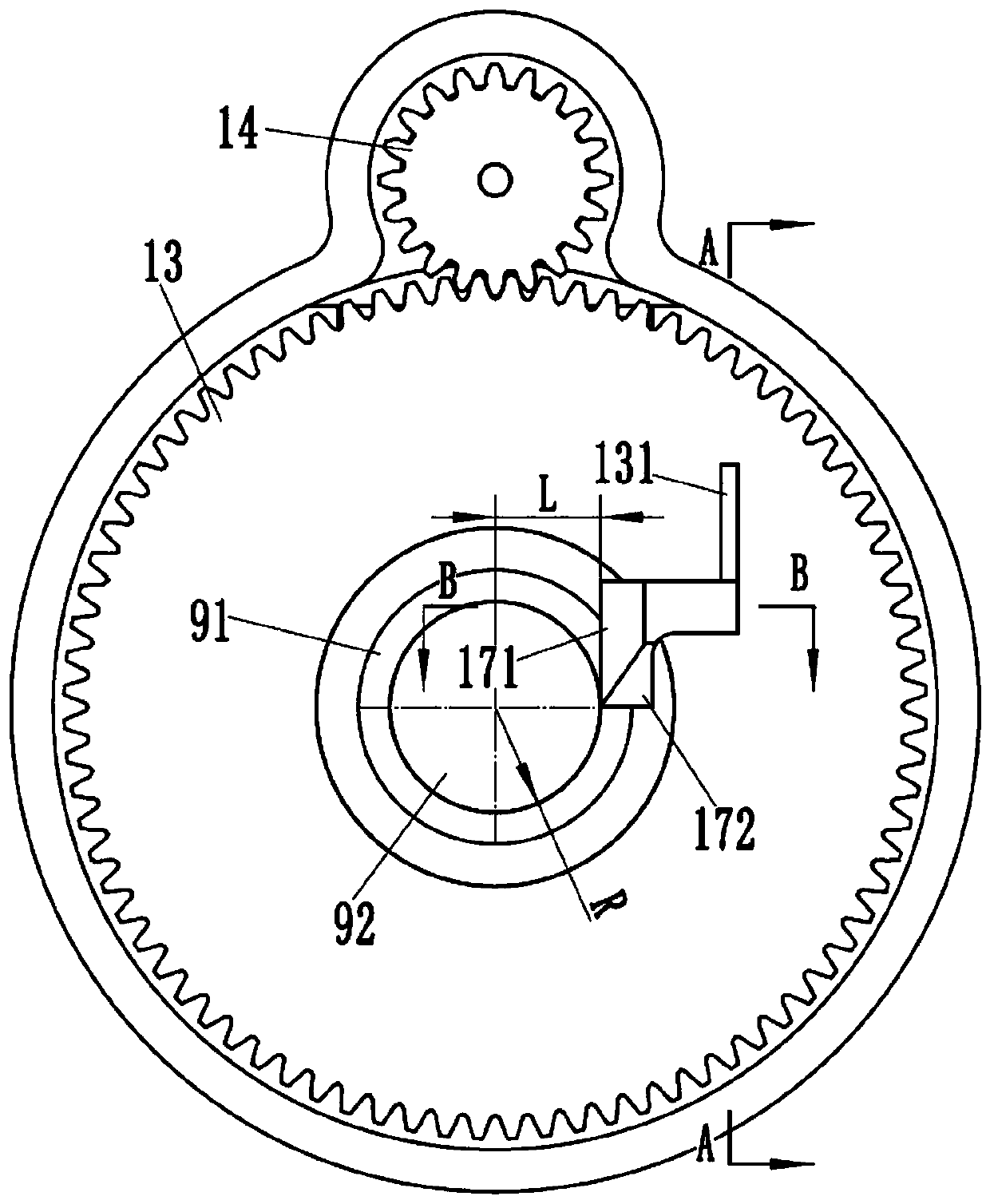

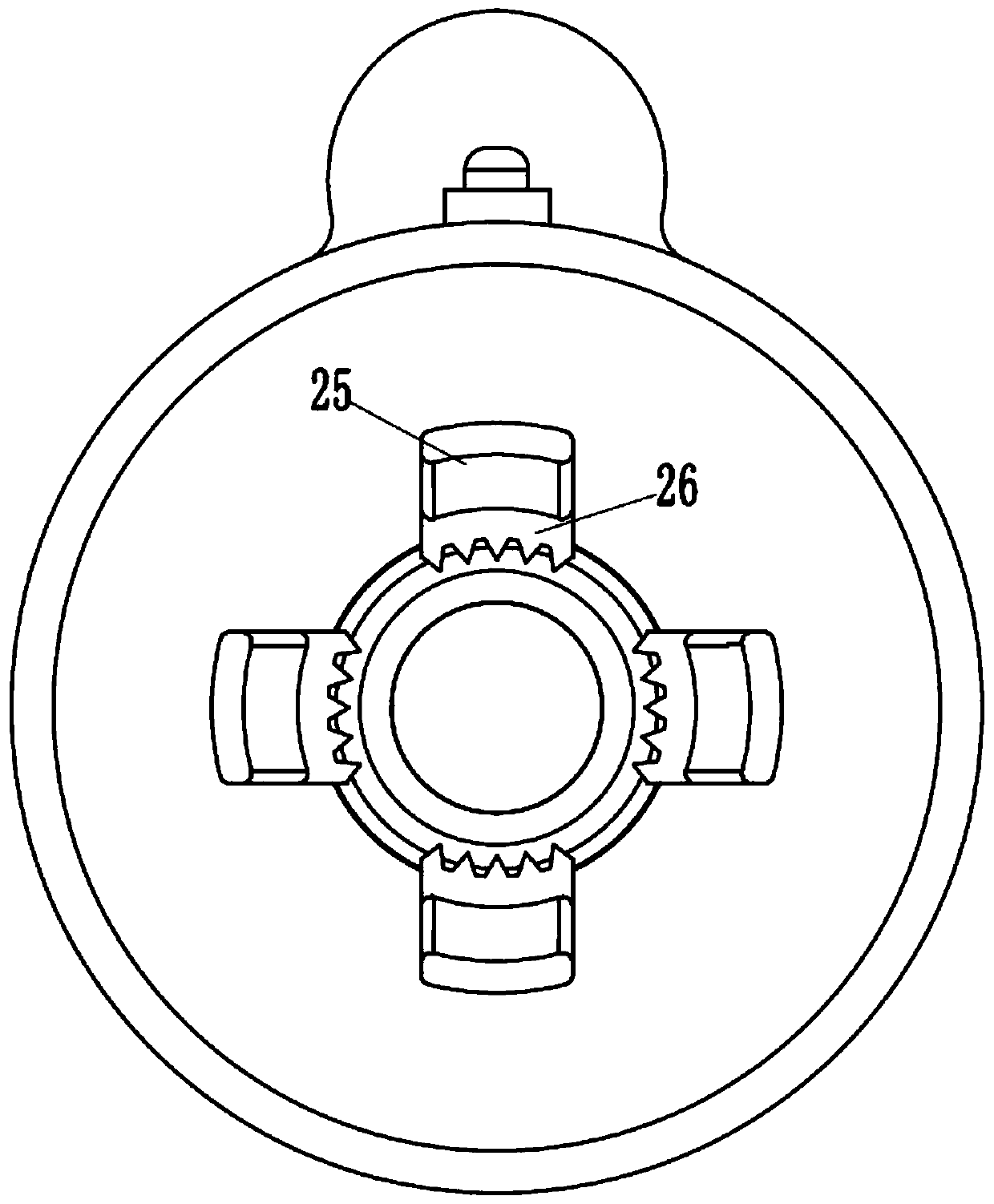

[0016] Examples, see e.g. Figure 1 to Figure 5 As shown, a wire and cable end stripping device includes a housing 11 with an opening on the right side, a bearing through hole 111 is formed on the left side wall of the housing 11, and a bearing through hole 111 is sleeved in the housing 11. The guide tube 12 arranged at the center of the shaft, the left end of the guide tube 12 is hinged in the bearing through hole 111 through the first bearing, the right end of the guide tube 12 is fixed with a large gear 13, and the upper end of the large gear 13 is meshed with a pinion 14, and the pinion 14 It is fixedly connected with the motor shaft of the first motor 15 fixed on the housing 11. The big gear 13 is formed with a rectangular hole 131 penetrating left and right, and a movable rectangular connecting arm 16 is sleeved in the rectangular hole 131. The rectangular connection The right extension end of the arm 16 passing through the rectangular hole 131 is fixed with a cutting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com