bsrmwr torque ripple suppression method based on turn-on and turn-off angle control

A torque ripple, on-off technology, applied in the control field of bearingless switched reluctance motor to suppress torque ripple, can solve problems such as motor noise and limited application, achieve convenient control, enhance reliability and stability, improve Effects on torque and suspension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further clarified in conjunction with the accompanying drawings and specific embodiments, and it is to be understood that these examples are intended to illustrate the invention, and those skilled in the

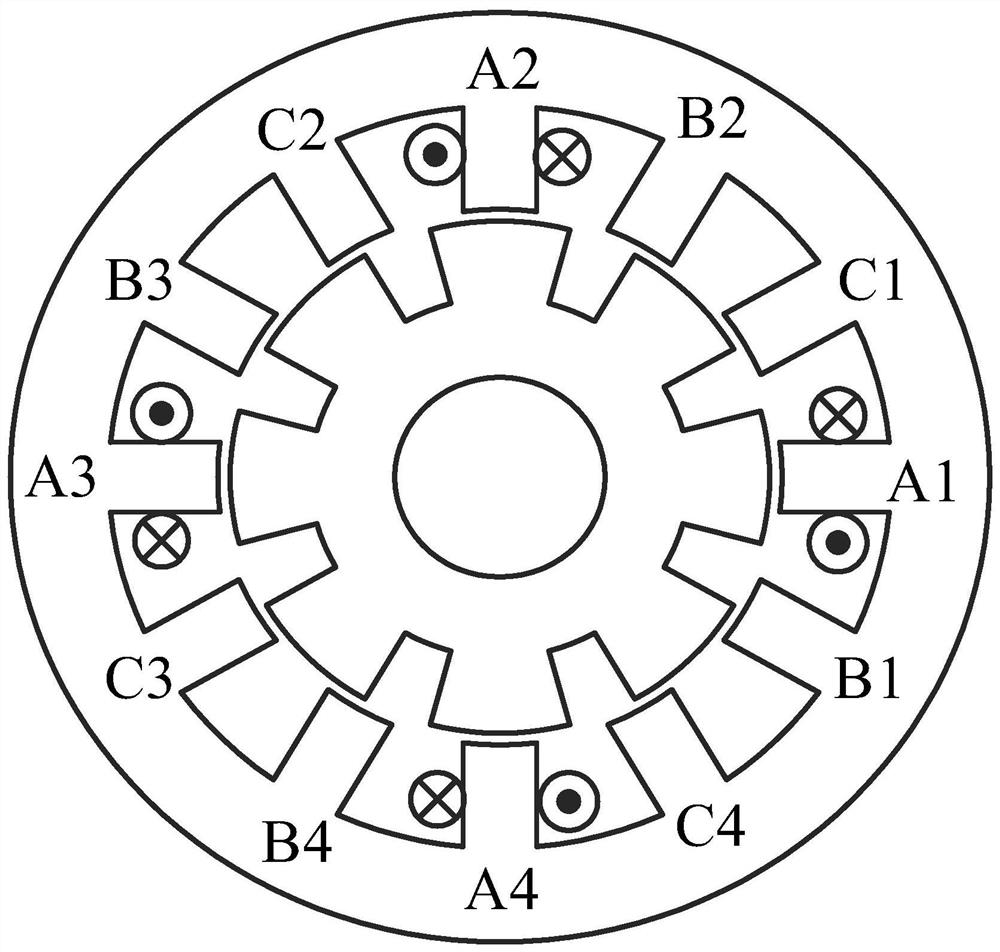

[0038] Motor structure figure 1 As shown, 12 tumored stator teeth, 8 male rotor teeth, windings, rotating shafts; the mechanical angle of the rotor pole arc is 30 °, the mechanical angle of the stator pole arc is 15 °, and there is a set of 12 sets. Winding, a total of 12 windings, the voltage, current can be controlled separately, in contrast, inverted in the winding direction of the two windings, the flow in the current direction, the magnetic field formed by the four windings is distributed, every 90 The four-phase windings of the needle, and the 12 windings finally form a A, B, C three-phase windings that differ from 30 ° on the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com