An electromechanical control based hot pressing device for car mat fabric processing

A technology for automobile mats and electromechanical control, applied in the directions of lamination devices, lamination, chemical instruments and methods, etc., can solve the problems of inconvenient operation of hot-pressing composite technology, and achieve the effect of avoiding excessive hot-pressing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

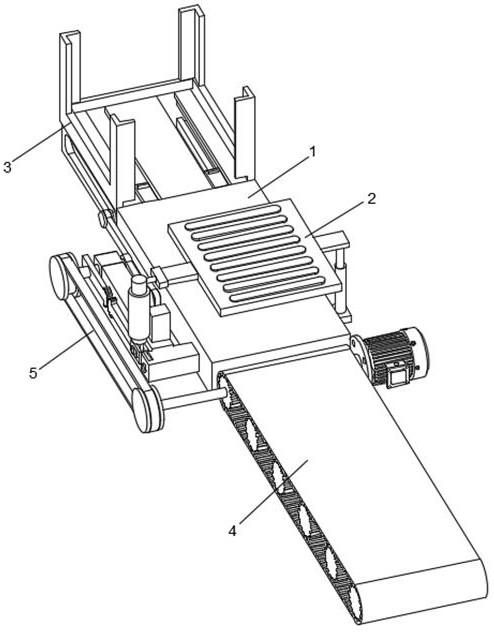

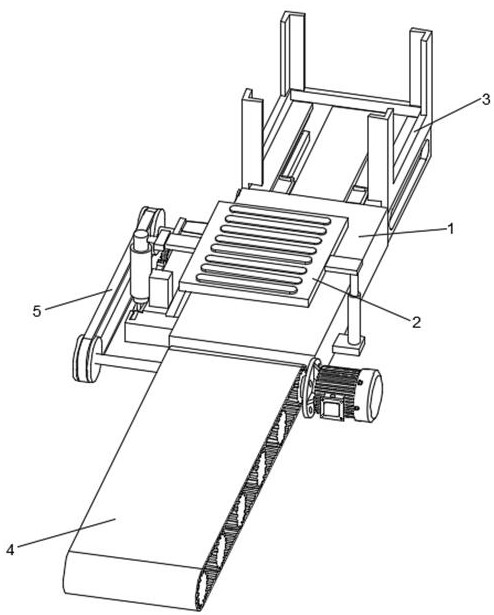

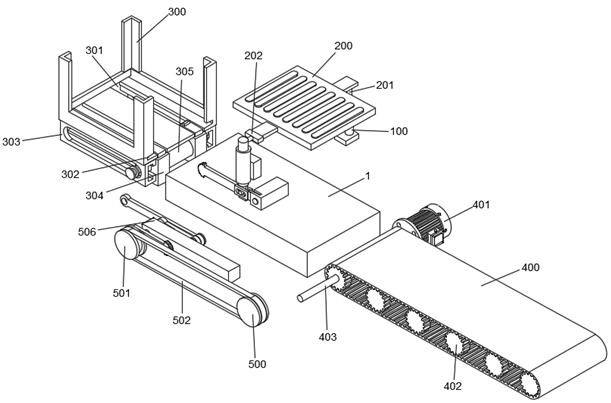

[0033] A heat-pressing device for processing automobile floor mat fabrics based on electromechanical control, including a workbench 1, a heat-press assembly 2 is movably installed above the workbench 1, the rear end of the workbench 1 is fixedly connected to the front end of the bearing assembly 3, and the front end of the workbench 1 is fixed A transmission assembly 4 is installed, and a transmission mechanism 5 is fixedly installed on the left side of the workbench 1. The rear part of the transmission mechanism 5 is rotationally connected with the side of the bearing assembly 3, the middle part of the transmission mechanism 5 is meshed with the rear end of the hot pressing assembly 2, and the front part of the transmission mechanism 5 It is fixedly connected to the left side of the transmission assembly 4, and a guide cylinder 100 is welded on the right side of the workbench 1, and the guide cylinder 100 is slidably connected to the right side of the hot pressing assembly 2. ...

Embodiment 2

[0035] Embodiment 2: the difference based on Embodiment 1 is;

[0036] The hot pressing assembly 2 includes a hot pressing panel 200, a guide rod 201, a connecting piece 202 and a limit rod 203;

[0037] An electric heating mechanism is installed inside the hot pressing panel 200, and the right side of the hot pressing panel 200 is fixedly connected to the upper end of the guide rod 201, the outer side of the guide rod 201 is slidingly connected to the inner side of the guide cylinder 100, and a connecting piece is fixedly connected to the left side of the hot pressing panel 200 202 , the end of the connecting piece 202 is fixedly connected with the upper end of the limit rod 203 .

[0038] The hot pressing assembly 2 also includes a fixed seat 204, a rotating member 205, an alveolar head A206, a sleeve 207 and a return spring A208;

[0039] The right end of the fixed seat 204 is fixedly connected with the left side of the workbench 1, and the rear side of the fixed seat 204 ...

Embodiment 3

[0041] Embodiment 3: the difference based on embodiment 1 and 2 is;

[0042] The bearing assembly 3 includes a fabric bearing box 300, a strip groove 301, a fabric push-out opening 302, a slider 303, a slider 304, a connecting column 305, a block 306, and a return spring B307;

[0043] The front end of the fabric carrying box 300 is tightly welded to the rear end of the workbench 1, and a fabric push-out opening 302 is provided on the front side of the fabric carrying box 300 close to the welding surface of the workbench 1, and two bar-shaped openings are arranged in parallel inside the fabric carrying box 300. Groove 301, two sliding parts 303 are also symmetrically welded on the bottom surface of the fabric bearing box 300, and the inside of the two sliding parts 303 is all slidably connected with a sliding block 304, and the two sliding blocks 304 are fixedly connected by a connecting column 305. Slidingly connected with a block 306, the width of the strip groove 301 is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com