Oil-palm fibre elastic material and its production

A technology of fiber elasticity and elastic materials, which is applied in the field of oil palm fiber elastic materials and its production, to achieve the effects of rational utilization of resources, high strength of latex, and increased vulcanization and shaping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention: the fiber silk of oil palm and mountain palm is decomposed, and the decomposition method of oil palm fiber silk is, after the petiole of oil palm is plucked, be cut into the petiole section of 30~60cm with cutting machine, dry Or dry it to a water content of 10-30%, then put the petiole segment into water at 80-120°C for 6-48 hours, roll it with a roller press, and comb it into silk. The decomposition of mountain palm fiber silk is carried out by prior art.

[0022] Then the fiber is curled and shaped into a spiral shape. The method of curling the oil palm fiber is to dry the oil palm fiber or dry it naturally, make a single-strand unidirectional spiral rope through a rope making machine, and then twist the fiber The spiral rope is placed in an environment of 70-130°C and kept for 10 minutes, so that the fiber filaments are shaped into a helical shape.

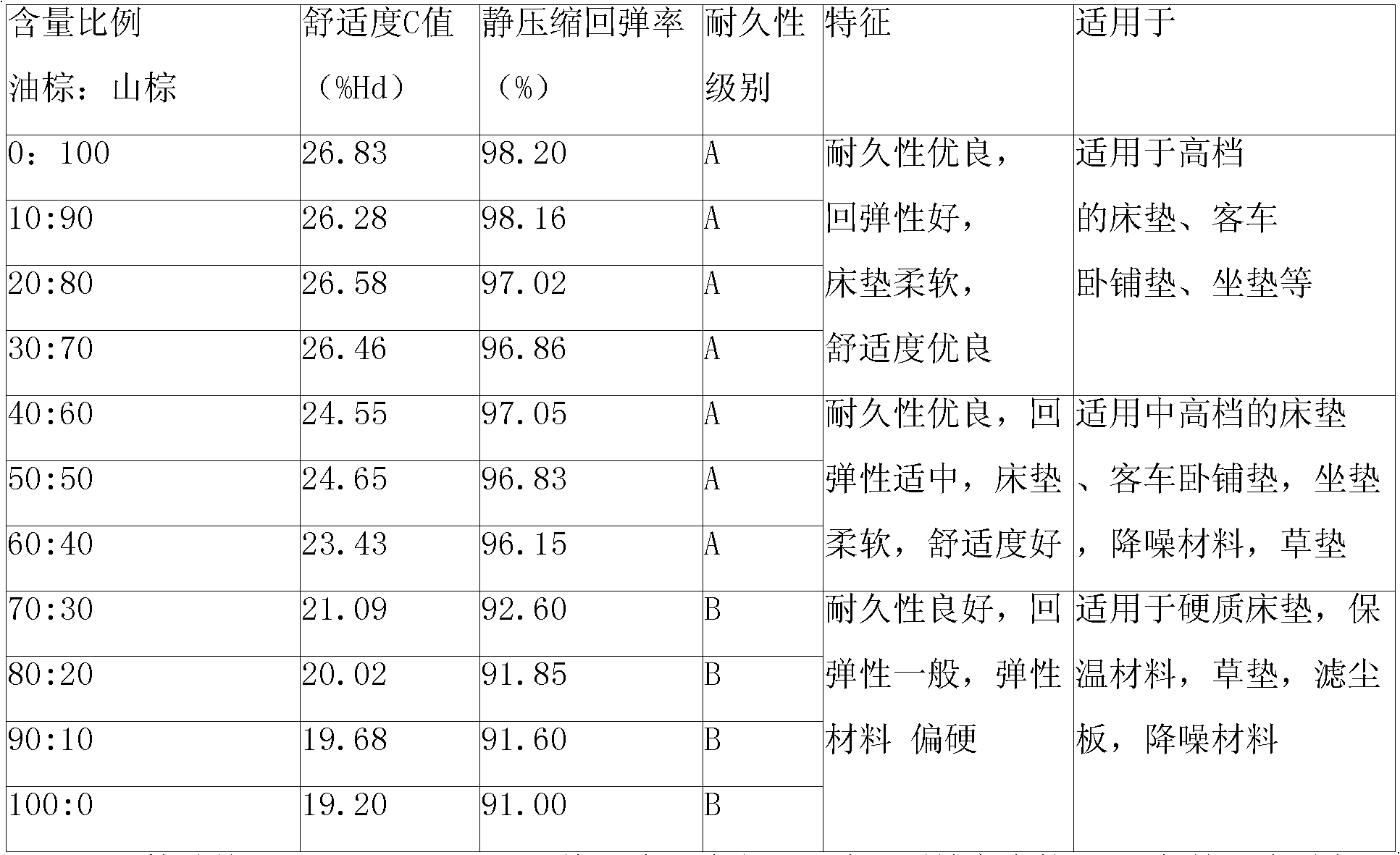

[0023] Mix the curled oil palm and mountain palm fibers evenly in the ratio o...

Embodiment 2

[0027] Embodiment 2 of the present invention: the fiber silk of oil palm and mountain palm is decomposed, and the decomposition method of oil palm fiber silk is, after the petiole of oil palm is plucked, be cut into the petiole segment of 40cm with cutting machine, dry or bake Dry to 20% water content, put the petiole segment in 120°C, pressure 0.2MPa, pH value 8 alkaline water, cook for 8 hours, roll with a roller press, and then comb into silk. The decomposition of mountain palm fiber silk is carried out by prior art.

[0028] Then the fiber is curled and shaped into a spiral shape. The method of curling the oil palm fiber is to dry the oil palm fiber or dry it naturally, make a single-strand unidirectional spiral rope through a rope making machine, and then twist the fiber The spiral rope is placed in an environment of 100°C for 10 minutes, so that the fiber filaments are shaped into a helical shape.

[0029] Mix the curled oil palm and mountain palm fibers evenly in the r...

Embodiment 3

[0033] Embodiment 3 of the present invention: decompose the fiber silk of oil palm and mountain palm, the decomposition method of oil palm fiber silk is, after the petiole of oil palm is picked, be cut into the petiole section of 50cm, put the petiole section into 80 ℃ After steaming for 30 hours in clear water, rolling and combing into silk. The decomposition of mountain palm fiber silk is carried out by prior art.

[0034] Then the fiber is curled and shaped into a spiral shape. The method of curling the oil palm fiber is to dry the oil palm fiber or dry it naturally, make a single-strand unidirectional spiral rope through a rope making machine, and then twist the fiber The spiral rope is placed in an environment of 90°C for 10 minutes, so that the fiber filaments are shaped into a helical shape.

[0035] Mix the curled oil palm and mountain palm fibers evenly at a ratio of 30% oil palm fiber silk and 70% mountain palm fiber silk, blow it into a three-dimensional evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com