A manufacturing process of hard ball liner for sports

A production process and technology of hard balls, applied in the direction of manufacturing tools, applications, balls, etc., can solve the problems of lack of uniformity of materials and structures, environmentally friendly selection of materials, and high production costs, reducing energy consumption, light weight, and production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

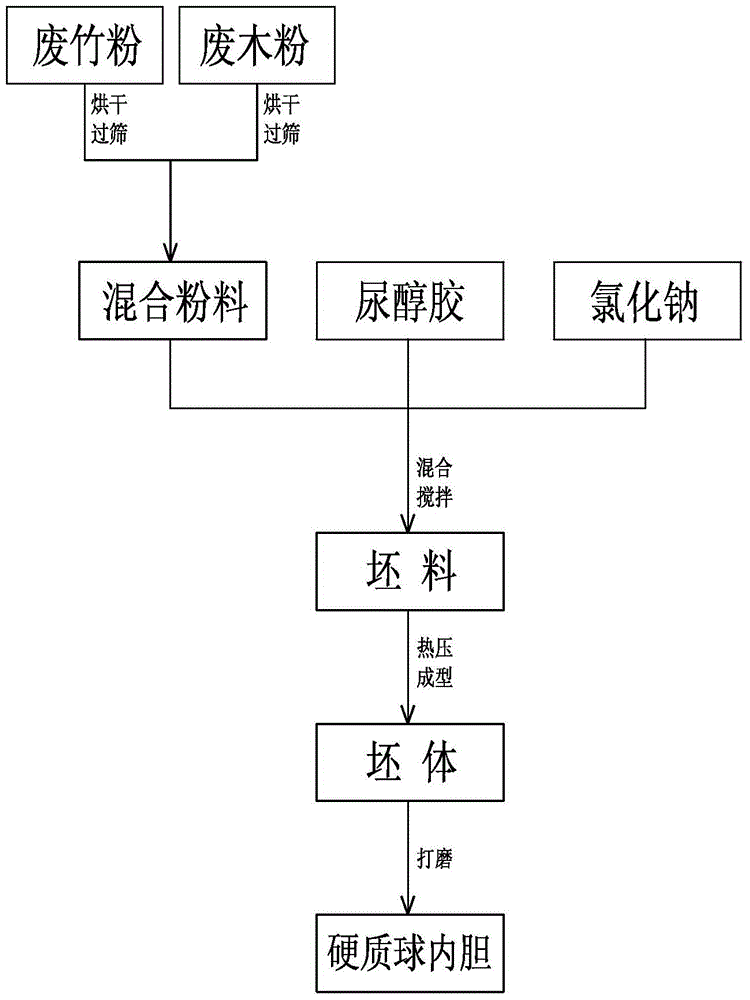

Method used

Image

Examples

specific Embodiment 1

[0023] Specific embodiment one: the invention provides a kind of weight that is 120 grams, and the manufacturing process of the hard ball liner that diameter is 6.5 centimeters comprises the following steps:

[0024] Step 1, collecting the waste bamboo powder and the waste Chinese fir powder respectively, drying the waste bamboo powder and the waste Chinese fir powder by steam at 110° C. for 3 minutes, and passing through a 100-mesh sieve to keep the fine powder;

[0025] Step 2, stirring waste bamboo powder and waste Chinese fir powder into mixed powder according to the ratio of 5:2;

[0026] Step 3, add urea alcohol gel and sodium chloride to the mixed powder, and then fully stir to obtain a blank, in parts by weight: 62% of the mixed powder, 37.8% of urea alcohol gel, and 0.2% of sodium chloride;

[0027] Step 4, the billet is weighed and then hot-pressed into a spherical billet. When the billet is weighed, the billet weight is 130 grams. When hot-pressing, the hot-pressing...

specific Embodiment 2

[0030] The invention provides a hard ball liner for sports, which has a weight of 120 grams and a diameter of 6.5 cm. The manufacturing process of the hard ball liner comprises the following steps:

[0031] Step 1, collecting the waste bamboo powder and the waste Chinese fir powder respectively, drying the waste bamboo powder and the waste Chinese fir powder by steam at 120° C. for 4 minutes, and passing through a 100-mesh sieve to keep the fine powder;

[0032] Step 2, stirring waste bamboo powder and waste Chinese fir powder into mixed powder according to the ratio of 6:1;

[0033] Step 3, add urea alcohol gel and sodium chloride to the mixed powder, and then fully stir to obtain a blank, in parts by weight: 65% of the mixed powder, 34.7% of urea alcohol gel, and 0.3% of sodium chloride;

[0034] Step 4, the billet is hot-pressed into a spherical green body after being weighed. When the billet is weighed, the weight of the billet is 140 grams. The time is 12 minutes;

[00...

specific Embodiment 3

[0037] The invention provides a hard ball inner container for sports, the weight of which is 800 grams and the diameter is 9 cm. The manufacturing process of the hard ball inner container comprises the following steps:

[0038] Step 1, collect waste waste bamboo powder and waste Chinese fir powder respectively, and dry the waste bamboo powder and waste Chinese fir powder by steam at 130°C for 5 minutes and pass through a 100-mesh sieve to keep the fine powder;

[0039] Step 2, stirring waste bamboo powder and waste Chinese fir powder into mixed powder according to the ratio of 6:1;

[0040] Step 3, adding urea alcohol gel and sodium chloride to the mixed powder and then fully stirring to obtain a blank, in parts by weight: 68% of the mixed powder, 31.6% of urea alcohol gel, and 0.4% of sodium chloride;

[0041] Step 4, the billet is hot-pressed into a spherical green body after being weighed. When weighing the billet, the billet weight is 850 grams. The hot-pressing pressure d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com