Method and device for determining linearization curve of printing equipment

A printing equipment and linearization technology, which is applied in the field of determining method and device for the linearization curve of printing equipment, can solve problems such as poor accuracy of Nelson coefficient, linearization curve of printing equipment does not conform to printing standards, etc., and achieve the effect of accurate generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

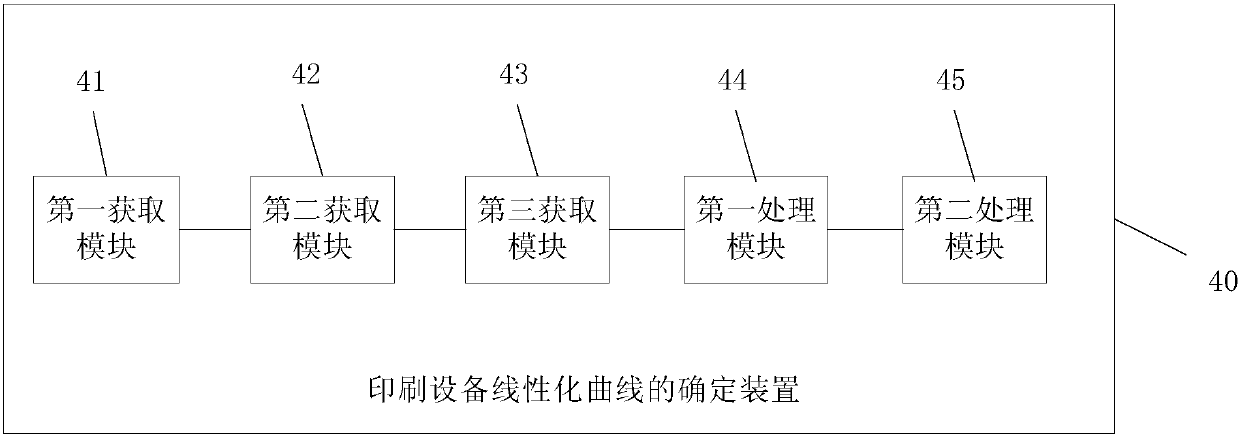

[0023] This embodiment provides a method for determining a linearization curve of a printing device, which is used for determining the linearization curve of a printing device. The executor of this embodiment is the device for determining the linearization curve of the printing equipment, and the device can be set in terminal devices such as servers, PCs, and tablet computers.

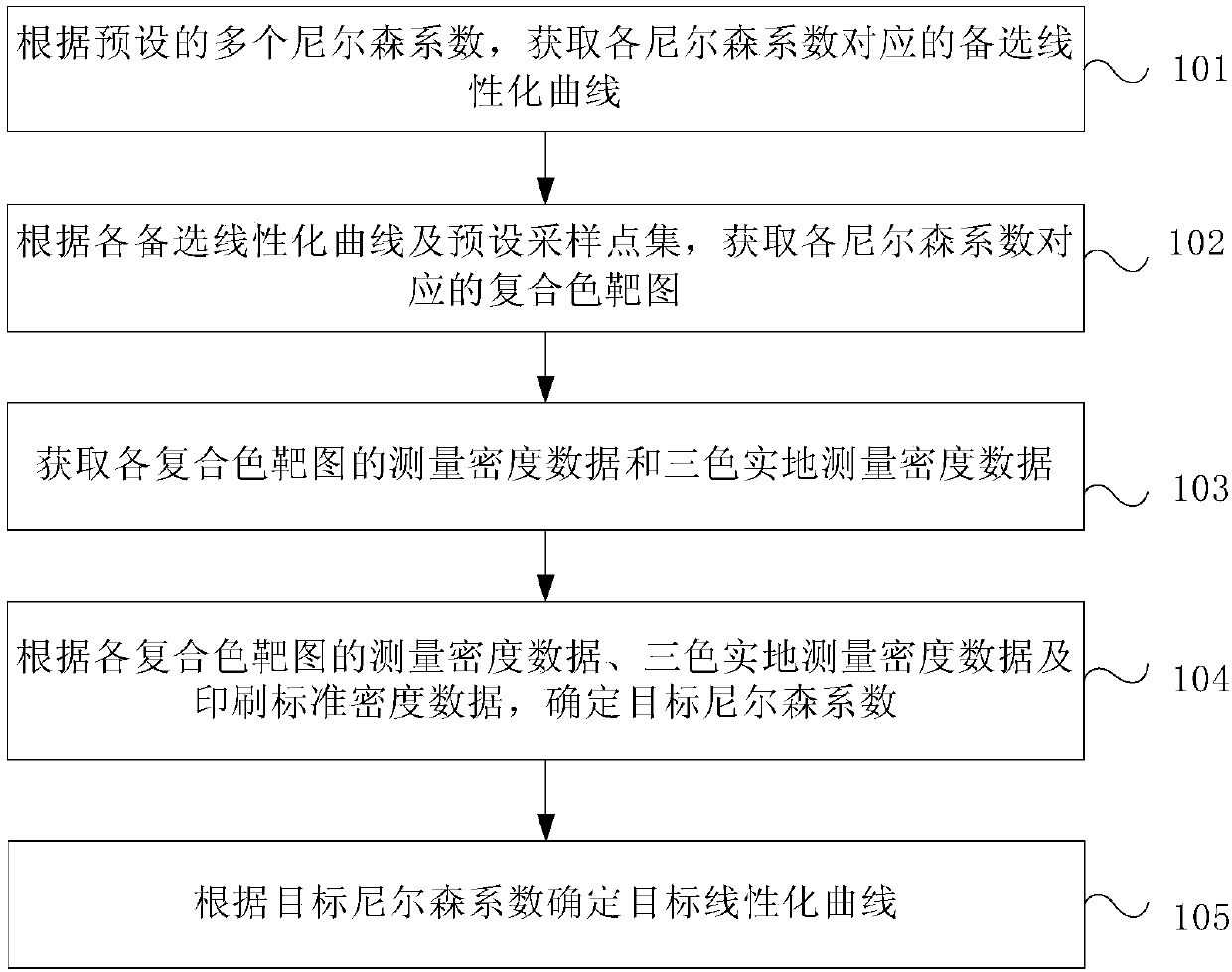

[0024] Such as figure 1 As shown, it is a schematic flow chart of the method for determining the linearization curve of the printing equipment provided in this embodiment, and the method includes:

[0025] Step 101 , according to a plurality of preset Nielsen coefficients, obtain an alternative linearization curve corresponding to each Nielsen coefficient.

[0026] Step 102, according to each candidate linearization curve and the preset sampling point set, obtain the composite color target map corresponding to each Nelson coefficient.

[0027] Step 103, acquiring the measured density data of each com...

Embodiment 2

[0033] This embodiment provides a further supplementary description of the method for determining the linearization curve of the printing device provided in the first embodiment.

[0034] As an implementable manner, on the basis of the first embodiment above, optionally, step 101 may specifically include:

[0035] Step 2011, obtain the ladder color target map according to the set of preset input points.

[0036] Step 2012, acquiring the scale measurement density and the scale maximum measurement density of the scale color target image.

[0037] Step 2013, obtain the corresponding standard reference density according to the maximum measured density of the ladder scale and a plurality of preset Nelson coefficients.

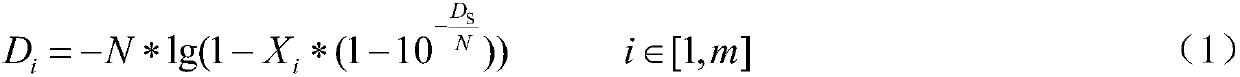

[0038] Specifically, the following formula (1) is used to obtain the corresponding standard reference density:

[0039]

[0040] Among them, D s is the maximum measured density of the ladder, N is the Nielsen coefficient, X i Represents the value of the i-th ...

Embodiment 3

[0073] This embodiment further describes in detail the method for determining the linearization curve of the printing device provided in the above embodiments.

[0074] The method may specifically include the following four steps:

[0075] Step 1. Obtain multiple linearization curves corresponding to multiple Nelson coefficients

[0076] Setting the linearization curve of k printing equipment is represented by the following expression:

[0077] In={X 1 ,X 2 ,...,X i ,...,X m} X i ∈[0,100]

[0078] Out={Out 1 ,Out 2 ,...,Out j ,...,Out k} j∈[1,k]

[0079] out j ={Y 1 ,Y 2 ,...,Y i ,...,Y m} Y i ∈[0,100]

[0080] Among them: In represents the set of input points (the unit is a percentage), m represents the number of In, X i Represents the value of the input point; Out represents the output point set of k linearization curves; Out j Indicates the set of output points of the jth equipment linearization curve, Y i Represents X in the jth linearization curve i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com