Stone carving machine

A technology of engraving machine and stone, applied in decorative arts, processing models, etc., can solve the problems of inconvenient maintenance and cleaning, and achieve the effect of good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

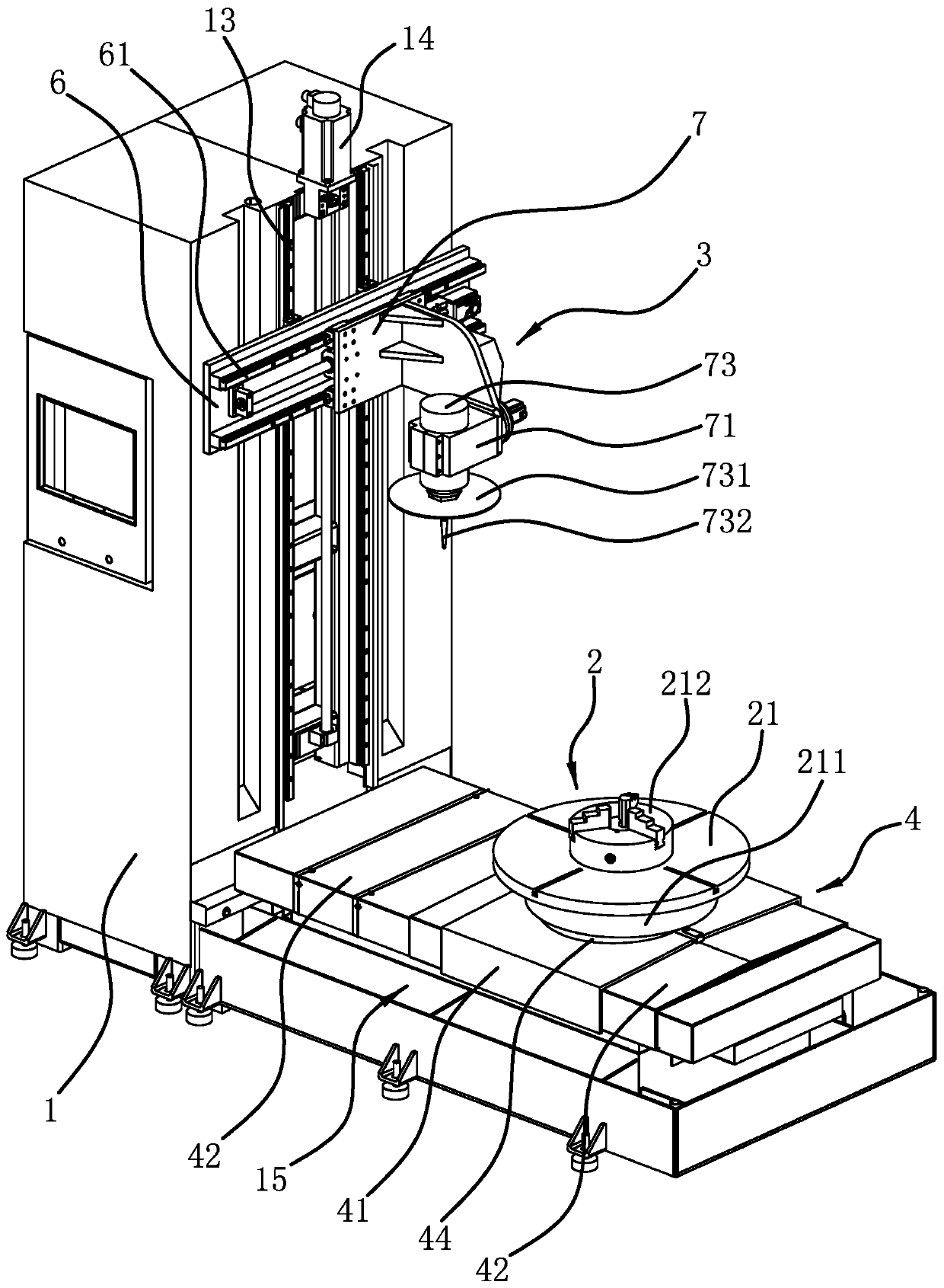

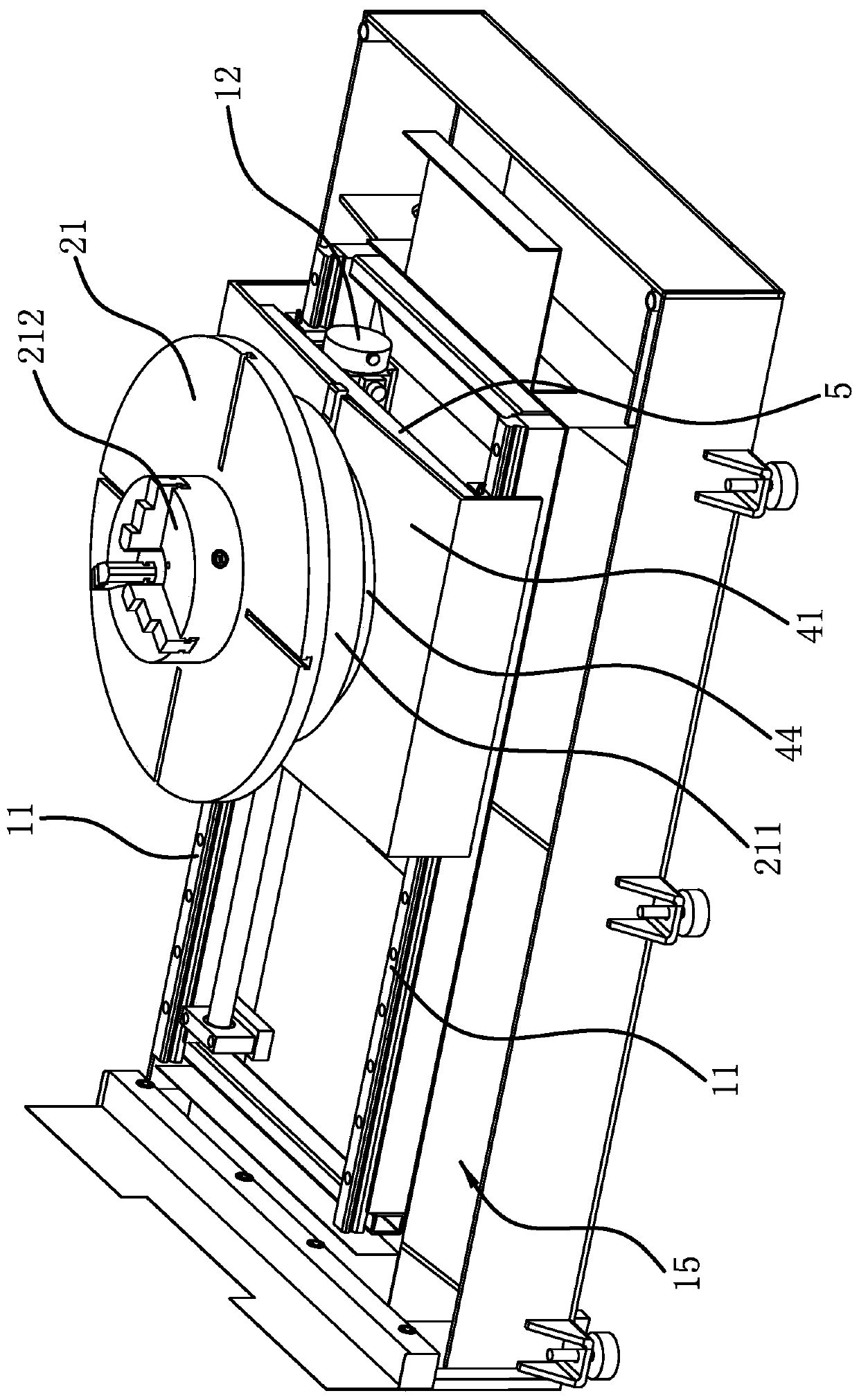

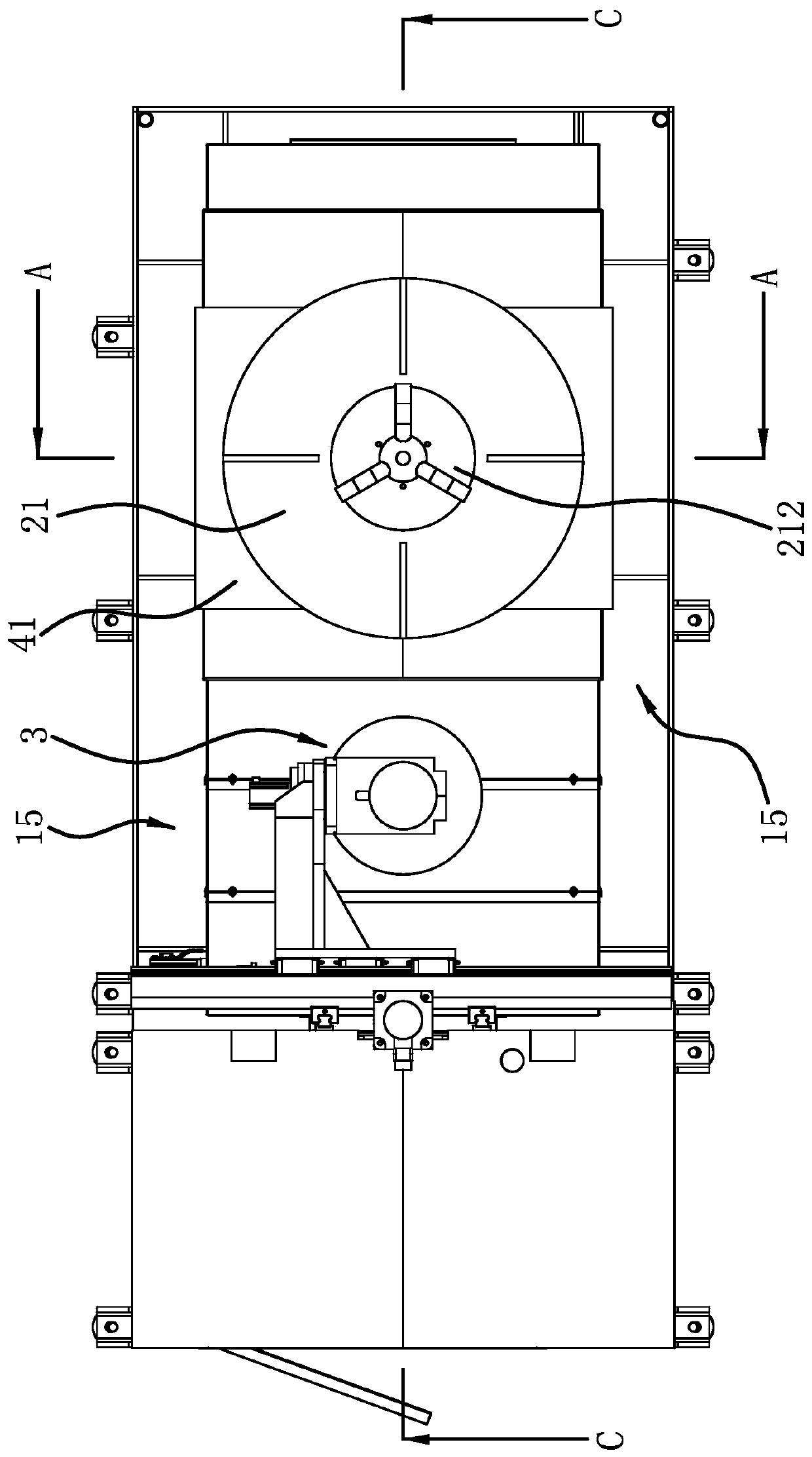

[0035] Such as figure 1 As shown, a stone engraving machine includes a frame 1, a processing assembly 3 and a processing table 2, a pair of vertical slide rails 13 are vertically fixed on the top of the frame 1, and vertical slide rails 13 are slidably connected with vertical The carriage 6 is also provided with a vertical motor 14 on the frame 1, and the vertical motor 14 drives the vertical carriage 6 to slide vertically through the cooperation of the screw nut. A pair of horizontal slide rails 61 are horizontally fixed on the vertical carriage 6, and the horizontal carriage 7 is slidably connected to the horizontal slide rails 61. A horizontal motor 62 is also arranged on the vertical carriage 6, and the horizontal motor 62 passes through a screw nut. Cooperate to drive the horizontal carriage 7 to slide laterally. A rotatable steering seat 71 is connected on the horizontal carriage 7, and the rotation axis of the steering seat 71 is arranged laterally. Saw disc 731 and e...

Embodiment 2

[0039] The structure of the stone engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 10 As shown, the diversion sleeve 211 includes an outer body 2111 and an inner body 2112, the upper part of the outer body 211 is fixedly connected to the lower side of the turntable 21, the upper part of the inner body 2112 is located inside the lower part of the outer body 2111, and the inner body 2112 The top and the bottom of the outer casing 2111 are fixedly connected by screws, and the distance from the lower edge of the outer casing 2111 to the upper side of the waterproof cover 4 is greater than the height of the waterproof cover 44.

Embodiment 3

[0041] The structure of this stone engraving machine is basically the same as the second embodiment, the difference is that Figure 11 As shown, the inner sleeve body 2112 includes two arc-shaped deflectors 2113, the two ends of the two deflectors 2113 are respectively butted to form the inner sleeve body 2112, the distance from the lower edge of the outer sleeve body 2111 to the upper side of the waterproof cover 4 Greater than the height of the inner sleeve body 2112, the two deflectors 2113 can be directly removed at the screw loosening opening to facilitate the disassembly and assembly of the waterproof cover 44.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap