Liquid lifting device for accelerating aging of liquor with power ultrasonic waves

A liquid lifting and ultrasonic technology, which is used in the field of liquor aging, can solve the problems of liquid transportation that cannot be equal in volume and different liquid volumes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

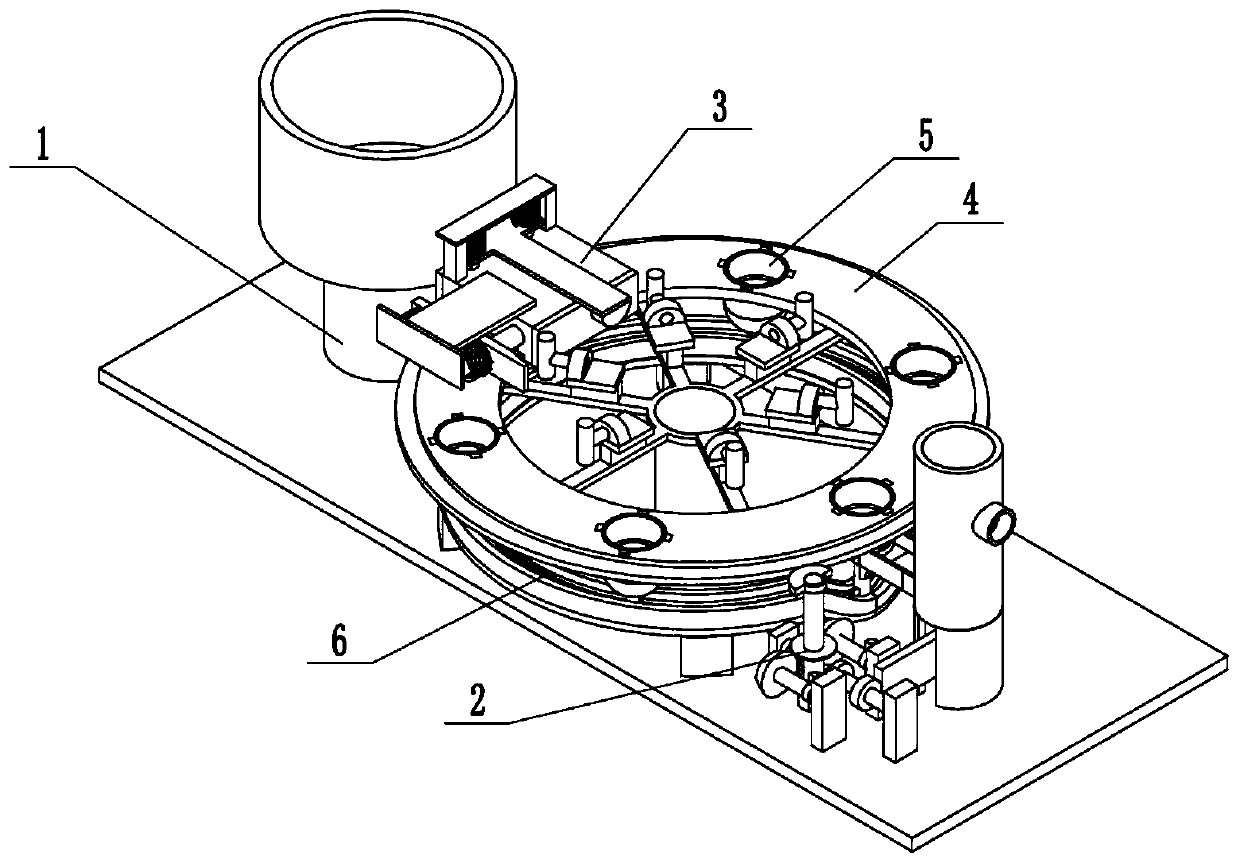

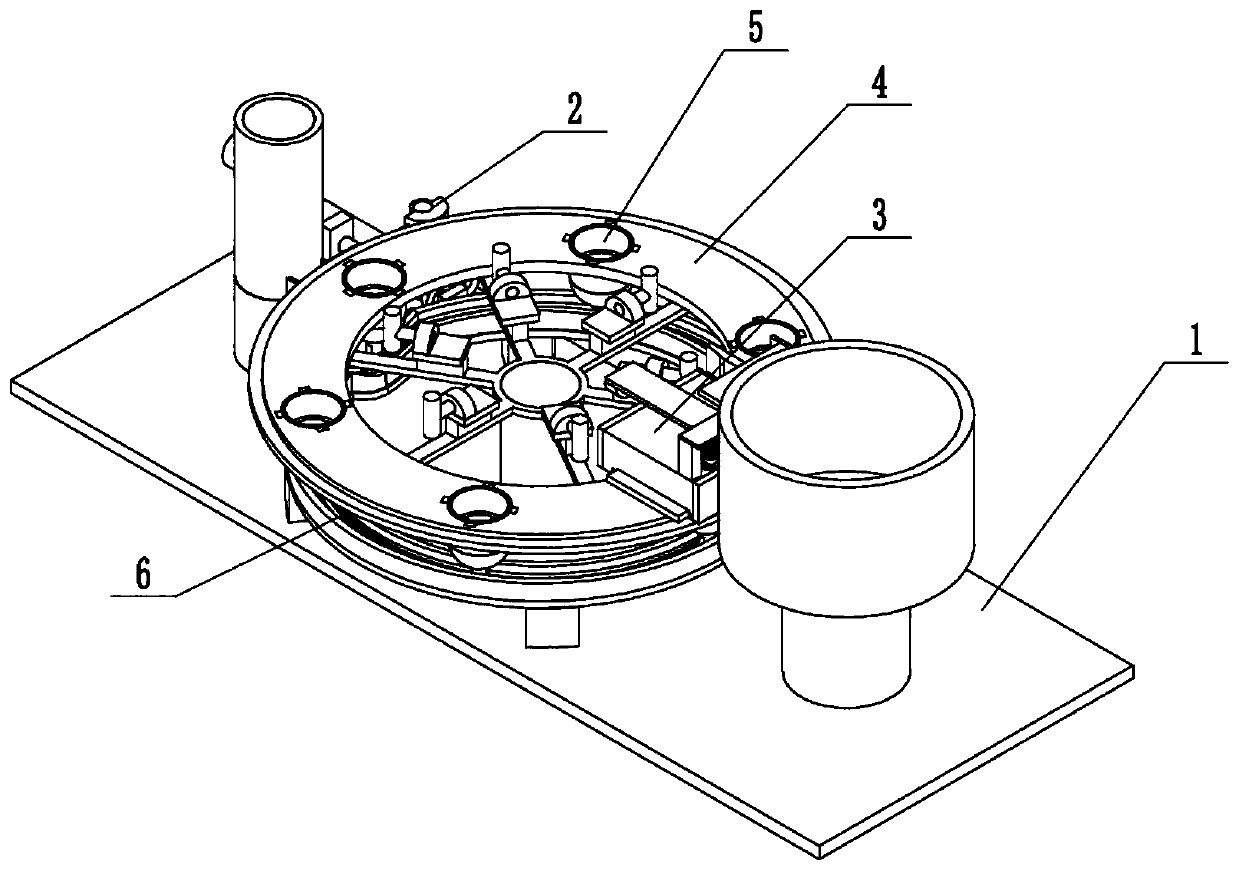

[0032] Such as Figure 1 to Figure 13 As shown, the power ultrasonic liquor aging liquid lifting device includes a material storage lifting base 1, a driver 2, a slow flow device 3, a rotating flow divider 4, six homogeneous transporters 5 and a sliding base 6, the described The driver 2 is rotatably connected to the material storage lifting base 1, the driver 2 is engaged with the rotating diverter 4 for transmission, the rotating diverter 4 is rotatably connected to the material storage lifting base 1, and the rotating diverter 4 is slidably connected to the slow flow device 3 Inside, the slow flow device 3 is fixedly connected to the material storage lifting base 1, the six homogeneous conveyors 5 are evenly plugged into the rotating diverter 4, and the six homogeneous conveyors 5 are all slidably connected to the sliding base 6 , the sliding base 6 is fixedly connected on the storage lifting base 1. Driven by the driver 2, the liquor stored in the storage lifting base 1 i...

specific Embodiment approach 2

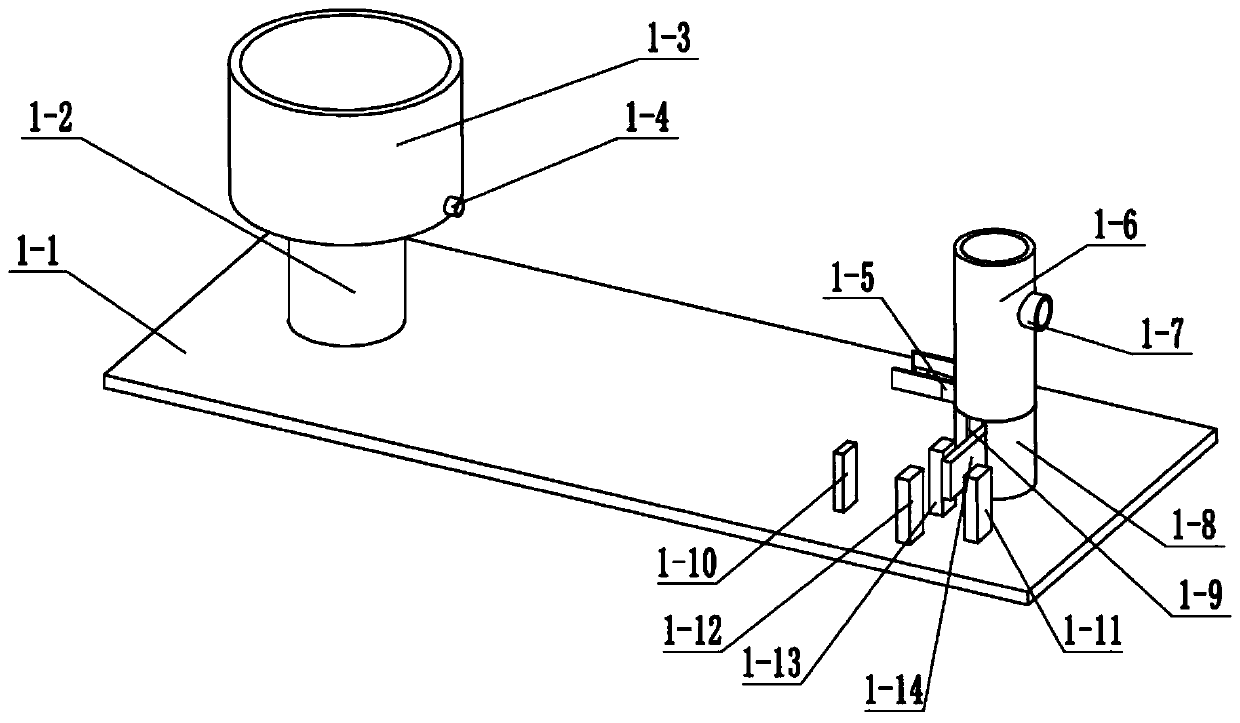

[0033] Such as Figure 1 to Figure 13 As shown, this embodiment will further explain Embodiment 1. The storage lifting base 1 includes a bottom plate 1-1, a storage tank base 1-2, a storage tank 1-3, a discharge pipe 1-4, Drainage frame 1-5, lifting cylinder 1-6, recovery pipe 1-7, fixed bottom frame 1-8, sliding opening 1-9, first rotating seat 1-10, second rotating seat 1-11, third rotating seat Seat 1-12, the fourth rotating seat 1-13, drive rack 1-14, push rod 1-15, receive push seat 1-16 and push sealing ring 1-17, storage tank base 1-2, fix The bottom frame 1-8, the first rotating seat 1-10, the second rotating seat 1-11, the third rotating seat 1-12 and the fourth rotating seat 1-13 are all fixedly connected on the base plate 1-1, and the material storage cylinder 1-3 is fixedly connected to the storage tank base 1-2, the discharge pipe 1-4 is fixedly connected to the right end of the storage tank 1-3, and the drainage frame 1-5 is fixedly connected to the lower side o...

specific Embodiment approach 3

[0034] Such as Figure 1 to Figure 13 As shown, this embodiment further explains the second embodiment, the driver 2 includes a servo motor 2-1, a main shaft 2-2, a main drive bevel gear 2-3, a semicircular drive gear 2-4, a double-toothed Drive gear 2-5, the first rotating shaft 2-6, the first driving circular gear 2-7, the second driving circular gear 2-8, the second driving rotating shaft 2-9, the first semicircle driving gear 2-10, the third Drive shaft 2-11, second semicircular drive gear 2-12, reciprocating drive gear 2-13, reciprocating drive shaft 2-14 and driven reciprocating drive gear 2-15, servo motor 2-1 is fixedly connected to base plate 1-1 Above, the main rotating shaft 2-2 is connected to the transmission shaft of the servo motor 2-1 through a coupling, the main driving bevel gear 2-3 is fixedly connected to the main rotating shaft 2-2, and the semicircular driving gear 2-4 is fixedly connected to the main rotating shaft 2 -2, the main driving bevel gear 2-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com