Transparent polyurethane coating composite and preparation method thereof

A technology of polyurethane coatings and compositions, applied in the direction of polyurea/polyurethane coatings, coatings, etc., which can solve problems that do not involve research on impact resistance, flexibility, and transparent polyurethane two-component coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

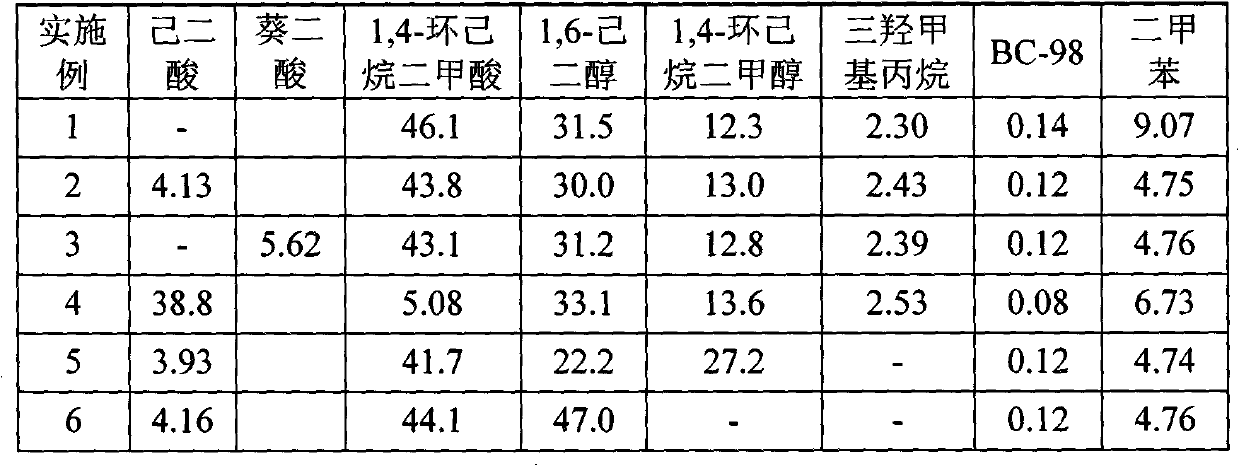

[0027] Synthesis of polyester polyols: according to the formula in Table 1, metered 1,4-cyclohexanedicarboxylic acid, 1,6-hexanediol, 1,4-cyclohexanedimethanol, trimethylolpropane were added to the general In a four-neck flask equipped with a thermometer and a stirrer under nitrogen, raise the temperature to 100-110°C, add catalyst BC-98 and azeotropic solvent xylene into the reaction system, raise the temperature to 140°C, keep it warm for 30min, and then gradually raise the temperature to 210°C ℃, the measured acid value is less than 1.0mgKOH / g, cool down and discharge. The hydroxyl value of the synthesized polyester polyol is 93.8, the acid value is 0.37, the number average molecular weight is 3066, and the molecular weight distribution is 1.25.

Embodiment 2

[0029] Synthesis of polyester polyols: according to the formula in Table 1, metered adipic acid, 1,4-cyclohexanedicarboxylic acid, 1,6-hexanediol, 1,4-cyclohexanedimethanol, trimethylol Add propane to a four-neck flask equipped with a thermometer and a stirrer with nitrogen, raise the temperature to 100-110°C, add catalyst BC-98 and azeotropic solvent xylene into the reaction system, raise the temperature to 140°C, keep it warm for 30min, and then Gradually raise the temperature to 210°C, the measured acid value is less than 1.0mgKOH / g, cool down and discharge. The hydroxyl value of the synthesized polyester polyol is 86.1, the acid value is 0.5, the number average molecular weight is 3127, and the molecular weight distribution is 1.26.

Embodiment 3

[0031] Synthesis of polyester polyol: according to the formula in Table 1, the synthetic method is shown in Example 2. The hydroxyl value of the synthesized polyester polyol is 84.8, the acid value is 0.54, the number average molecular weight is 3384, and the molecular weight distribution is 1.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com