3D glass television base, television and preparation method of 3D glass television base

A TV and glass technology, applied in the field of TV, can solve the problem of unsatisfactory explosion-proof treatment and achieve good explosion-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In addition, the present invention also proposes a method for preparing the above-mentioned 3D glass TV base, comprising the following steps:

[0032] Step 1. Mix 90-110 parts by weight of main agent with 1.5-5 parts by weight of curing agent to obtain a mixed solution, dilute the mixed solution with 10-20 parts by weight of diluent to obtain a paint; the model is NK- 2 Iwata viscosity cup to measure the viscosity of the paint is 18 to 22 seconds;

[0033] Step 2. Spray the paint on the surface of the base body 1 with a spray gun, and let it flow for 3-5 minutes at room temperature;

[0034] Step 3. Place the base body 1 in a tunnel furnace or an oven for heating and curing. After the paint is cured, the adhesion is greater than 4B, which meets the explosion-proof quality of glass falling ball breaking test without splashing.

[0035] Specifically, before the paint material in step 1 is mixed, the main agent is filtered with 300-400 mesh gauze to ensure that the light ...

Embodiment 1

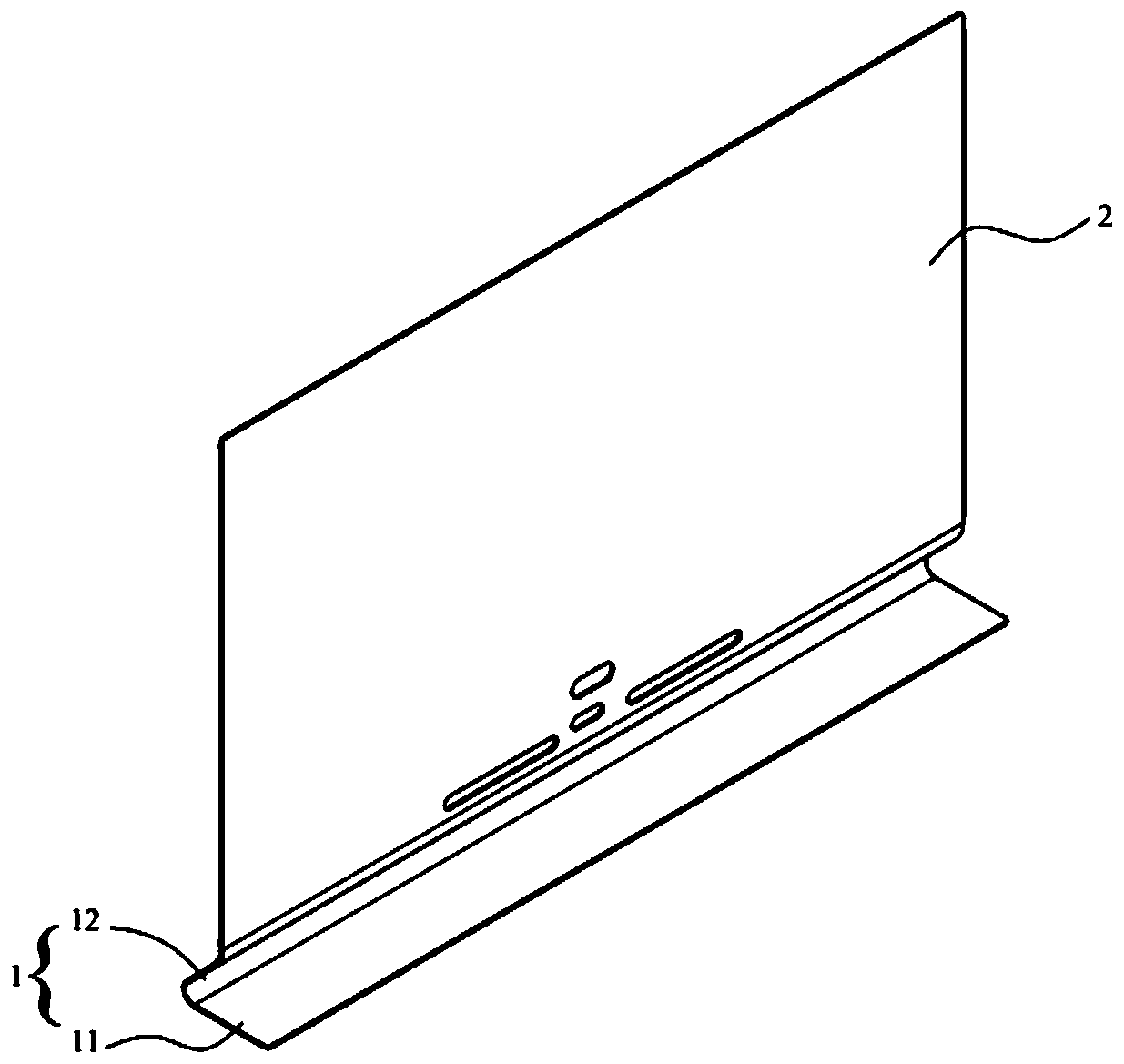

[0040] This embodiment proposes a TV, including a glass backplane 2 and the above-mentioned 3D glass TV base, the glass backplane 2 is located at the upper end of the base body 1, and the glass backplane 2 and the base body 1 are integrally formed. Its preparation method comprises the following steps:

[0041]S1. Using ultra-clear float glass material with a thickness of 4mm and a transmittance of 92% as raw material, it is processed by a CNC lathe and polished to smoothness. processing to obtain an integrated molding structure; on the surface of the glass back plate 2, use rollers to implement film explosion-proof and use a defoaming machine to remove bubbles. The thickness of the explosion-proof film is 0.12mm. One side is pasted with high temperature tape masking layer;

[0042] S2, adopt 300 mesh gauzes to filter the water-based polyurethane resin, mix the water-based polyurethane resin (particle diameter is 50nm) of 90g with 1.5g of toluene diisocyanate to obtain a mixed...

Embodiment 2

[0046] This embodiment proposes a TV, including a glass backplane 2 and the above-mentioned 3D glass TV base, the glass backplane 2 is located at the upper end of the base body 1, and the glass backplane 2 and the base body 1 are integrally formed. Its preparation method comprises the following steps:

[0047] S1. Using ultra-clear float glass material with a thickness of 4mm and a transmittance of 92% as raw material, it is processed by a CNC lathe and polished to smoothness. processing to obtain an integrated molding structure; on the surface of the glass back plate 2, use rollers to implement film explosion-proof and use a defoamer to remove bubbles. The thickness of the explosion-proof film is 0.13mm. One side is pasted with high temperature tape masking layer;

[0048] S2, adopt 400 mesh gauzes to filter the water-based polyurethane resin, the water-based polyurethane resin (particle diameter is 100nm) of 110g is mixed with the diphenylmethane diisocyanate of 5g, obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap