Construction method of pre-stressed pipeline on wet joint section of precast concrete component

A technology of prestressed pipes and prefabricated concrete, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., which can solve problems such as pipe blockage, easy breakage, and rupture, and achieve the effect of avoiding repair methods, low cost, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Example.

[0023] A construction method for a prestressed pipeline connection structure of a prefabricated concrete component wet joint, comprising the following steps.

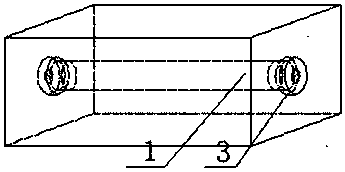

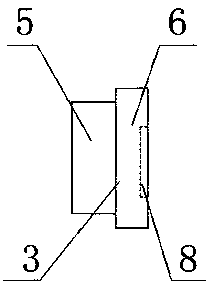

[0024] (1) Prefabricated concrete components are installed and fixed with prestressed pipeline pre-buried section 1 before pouring concrete, and plugs 3 are installed at both ends. The inner plug 5 of the plug is tightly inserted into the pre-embedded section 1 of the prestressed pipeline, and the outer side of the plug cap 6 is flush with the formwork of the prefabricated concrete component.

[0025] (2) After the initial setting of the concrete, pull out the plug 3 at the end of the embedded section 1 of the prestressed pipeline to form the joint part 4 of the prestressed pipeline.

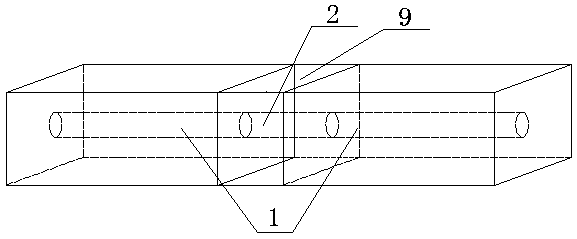

[0026] (3) Connect the connecting section 2 of the prestressed pipeline to the joint part 4 of the embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com