A construction method for prestressed pipes in wet joints of prefabricated concrete components

A technology for prestressed pipes and precast concrete, which can be used in construction, bridge construction, bridges, etc., can solve problems such as blocked pipes, ruptures, and easy breaking, and achieves the effect of avoiding repair methods, low cost, and preventing easy breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Example.

[0023] A construction method for a prestressed pipeline connection structure of a prefabricated concrete component wet joint, comprising the following steps.

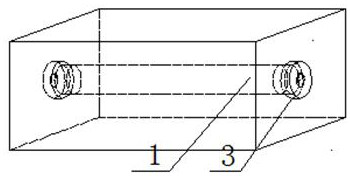

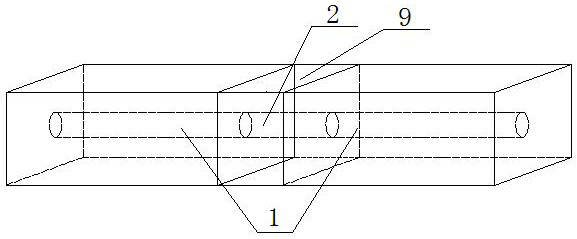

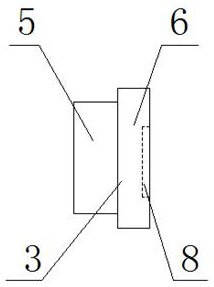

[0024] (1) Prefabricated concrete components are installed and fixed with prestressed pipeline pre-buried section 1 before pouring concrete, and plugs 3 are installed at both ends. The inner plug 5 of the plug is tightly inserted into the pre-embedded section 1 of the prestressed pipeline, and the outer side of the plug cap 6 is flush with the formwork of the prefabricated concrete component.

[0025] (2) After the initial setting of the concrete, pull out the plug 3 at the end of the embedded section 1 of the prestressed pipeline to form the joint part 4 of the prestressed pipeline.

[0026] (3) Connect the connecting section 2 of the prestressed pipeline to the joint part 4 of the embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com