A Small-diameter Tunnel Inverted Arch Concrete Transport Cart that Can Quickly Switch Tracks

A technology for transporting trolleys and fast switching, which is applied in the transportation of passenger cars, tunnels, railways, etc. It can solve the problems of concrete pipe blockage and the inability to directly transport concrete, and achieve the goal of avoiding pumping construction, reducing the risk of pipe blockage, and quickly switching tracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

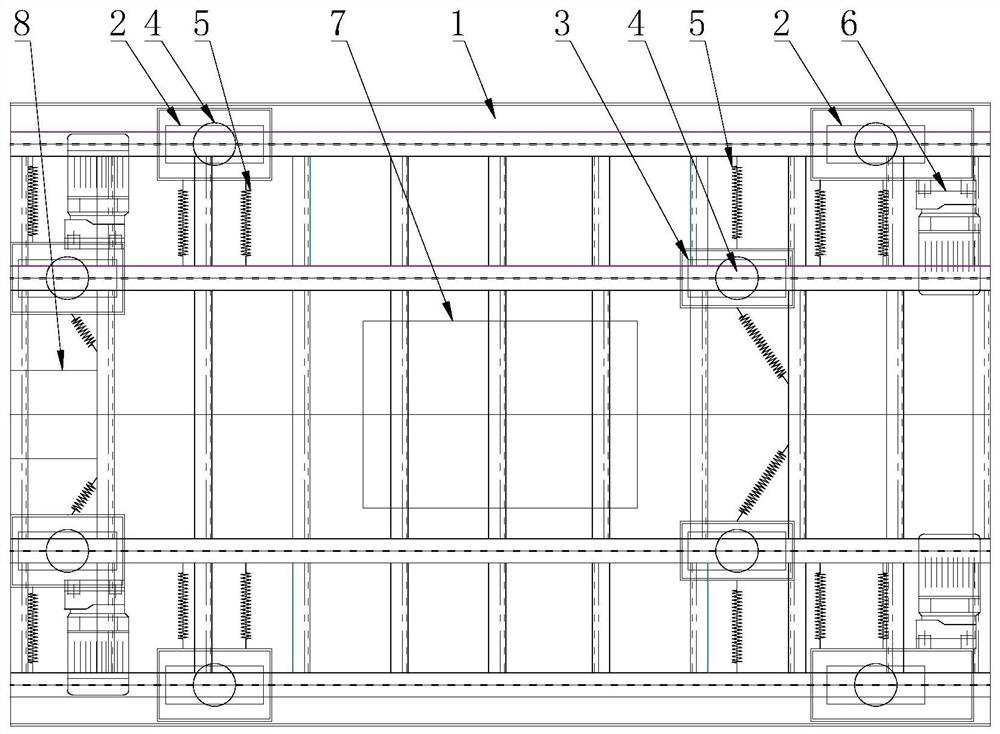

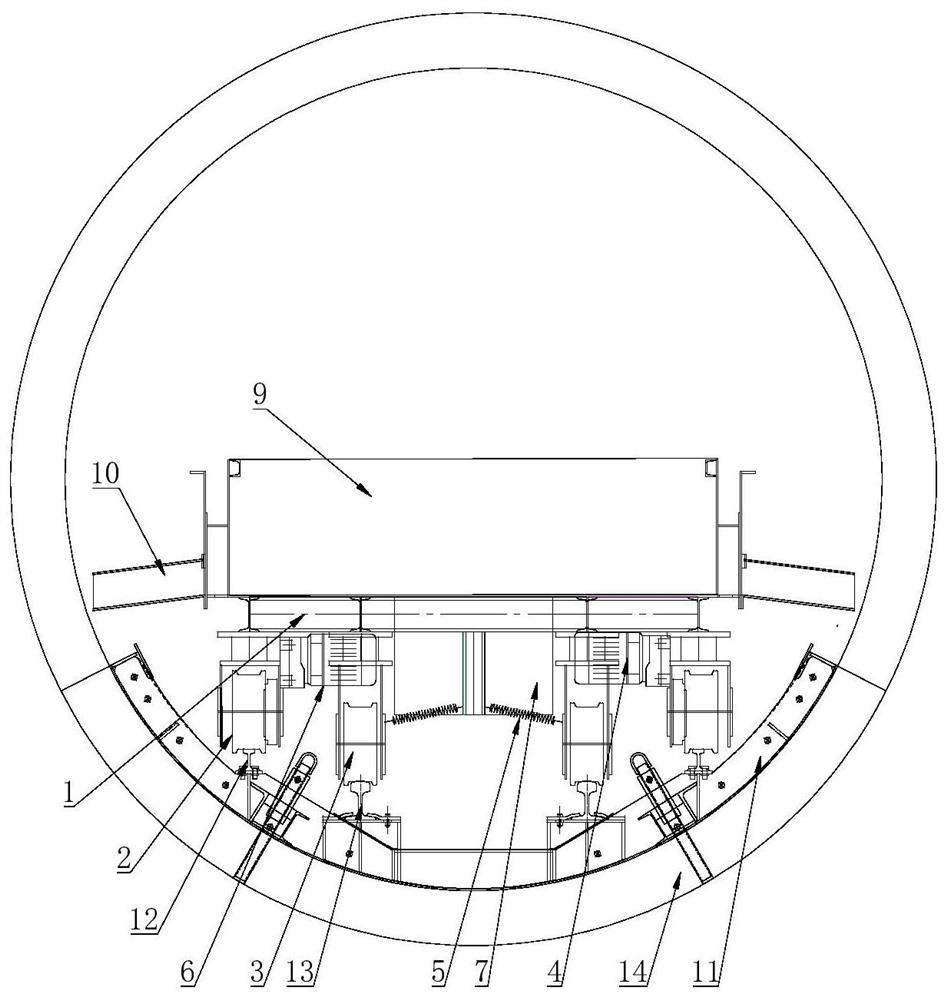

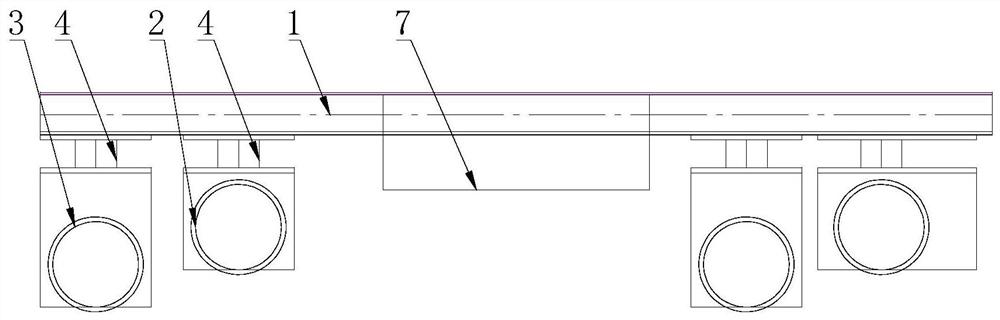

[0019] Such as figure 1 and figure 2 As shown, it is a top view and a right side view of a small-diameter tunnel inverted arch concrete transport trolley that can quickly switch tracks in the present invention, including a vehicle frame 1, a wheel set, a steering bearing 4, a limit spring 5, a gear motor 6, and a storage battery Group 7 and Control Box 8.

[0020] The bottom of vehicle frame 1 is equipped with 4 pairs of wheel groups, and wheel group is connected with vehicle frame 1 by steering bearing 4, can guarantee that wheel group adapts to track curve to rotate when the curve section walks.

[0021] One end of the limit spring 5 is welded on the side of the wheel group, and the other end is welded on the vehicle frame 1, which can ensure that when the non-curve section is walking, the wheel group returns to normal in time under the active force of the limit spring 5.

[0022] The four pairs of wheel sets are respectively two pairs of wide-gauge wheel sets 2 and two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com