Flash defect recognition method for complex injection molded products based on multi-template low-rank decomposition

A technology for injection molding products and low-rank decomposition, which is used in image analysis, instrumentation, computing and other directions to achieve the effects of high reliability, high detection robustness, and low requirements for image acquisition environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

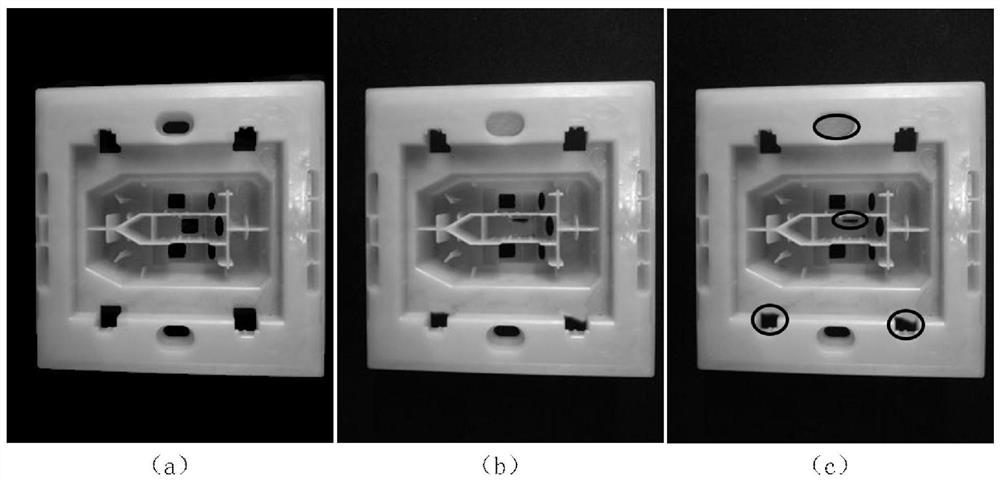

[0046] The method for identifying flash defects of complex injection molded products based on multi-template low-rank decomposition of the present invention will be further described below using the drawings and examples.

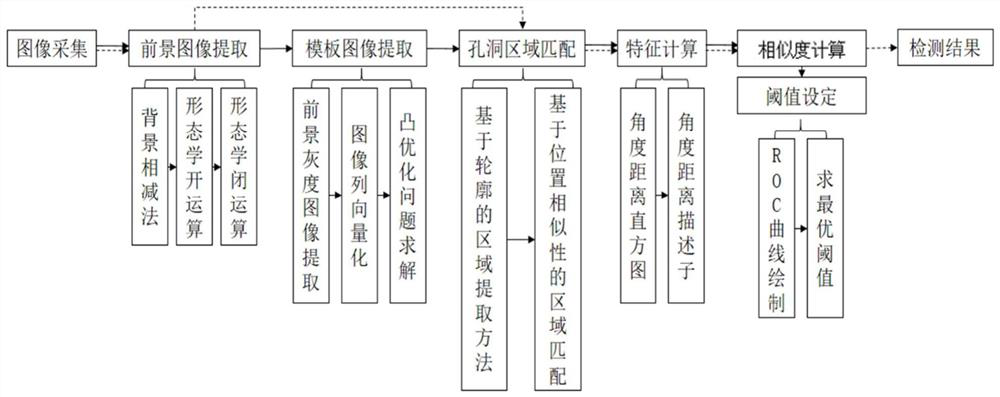

[0047] Such as figure 1 As shown, the solid line process represents the offline training stage, and the dotted line process is the online test stage. The present invention mainly includes the following steps:

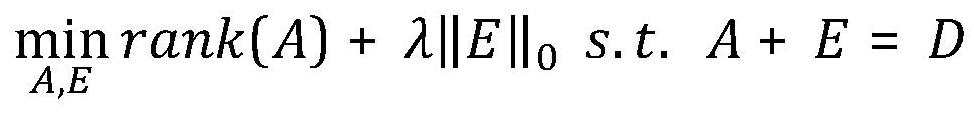

[0048] Step 1: Collect multiple images of injection molded products with flash defects under the background image as sample images, convert multiple sample images into corresponding initial grayscale images, and then use the background subtraction method to obtain multiple sample binary images and optimize. The step 1 specifically includes:

[0049] 1.1) Select a background with a large color difference from the injection molded product, collect a background image without an injection molded product and convert it into a background grayscale image,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com