PECVD film thickness automatic statistical compensation system

A technology of statistical compensation and film thickness, which is applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of difficult to obtain film thickness and high defect rate of products, and achieve the effect of reducing color difference film and avoiding debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

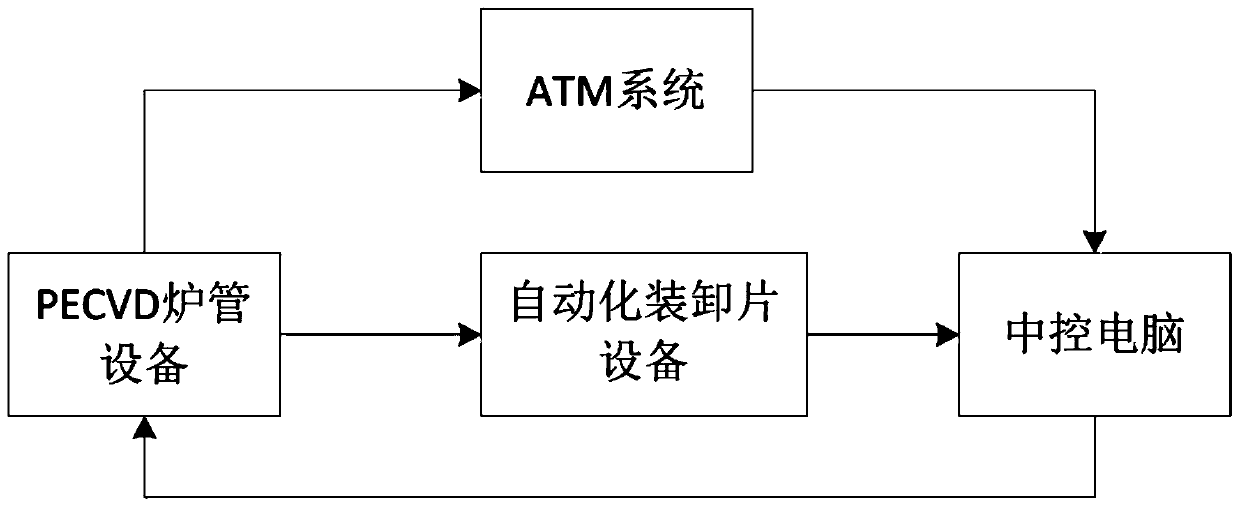

[0042] A PECVD film thickness automatic statistical compensation system, including PECVD furnace tube equipment, automatic loading and unloading equipment, is characterized in that it also includes an ATM system and a central control computer; the ATM system is used to collect PECVD furnace tube equipment and automatic loading and unloading equipment. The film thickness data of solar cells transmitted between them, and the collected film thickness data are transmitted to the central control computer; the central control computer is used to calculate the compensation time required for the solar cell coating process in the PECVD furnace tube equipment and The time is sent to the PECVD furnace tube equipment for process compensation.

Embodiment 2

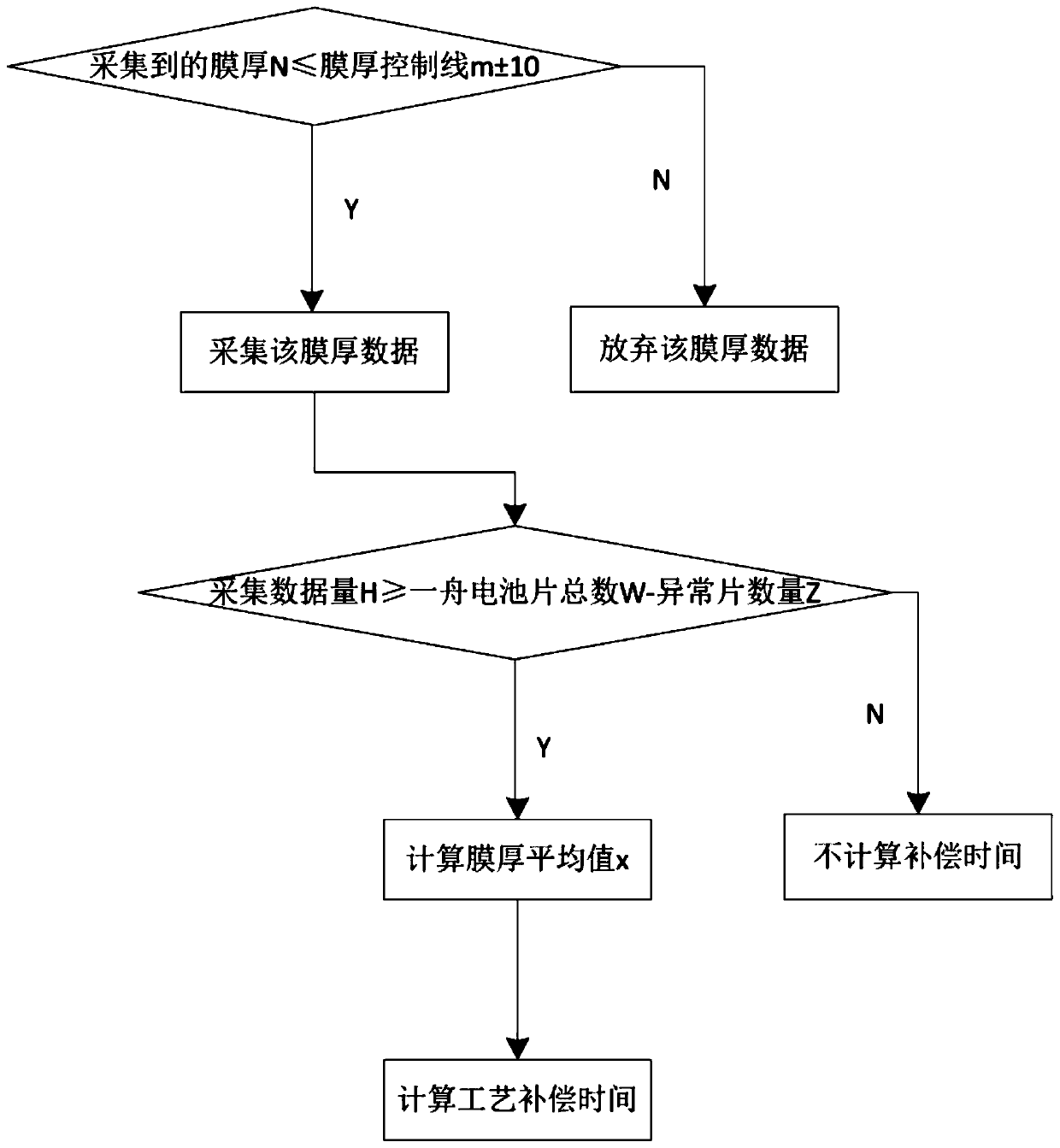

[0044] On the basis of Embodiment 1, the ATM system includes a film thickness acquisition module and a signal transmission module, and the film thickness acquisition module collects the film thickness data of each solar cell; the signal transmission module collects the film thickness collected by the film thickness acquisition module All the thickness data are sent to the central control computer; the central control computer also includes a communication module and a data processing module. The communication module is used to collect the film thickness data transmitted by the ATM system and the manually set film thickness control center value and film thickness control line. and the control number of abnormal film thickness; the data processing module processes the collected film thickness data on the basis of the set film thickness control center value, film thickness control line and abnormal film thickness control number; the communication module then The data processed by ...

Embodiment 3

[0046] On the basis of the above embodiments, when the number of abnormal film thickness slices exceeds the control number of abnormal film thickness slices, the PECVD furnace tube equipment will not perform process time compensation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com