Carbonless trolley

A carbon-free car and frame technology, which is applied in toy cars, toys, entertainment and other directions, can solve the problems of complex steering mechanism of carbon-free cars, reducing the steering sensitivity of the car, and low controllability of the walking trajectory, so as to improve the energy utilization rate. , The effect of less intermediate parts and less resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

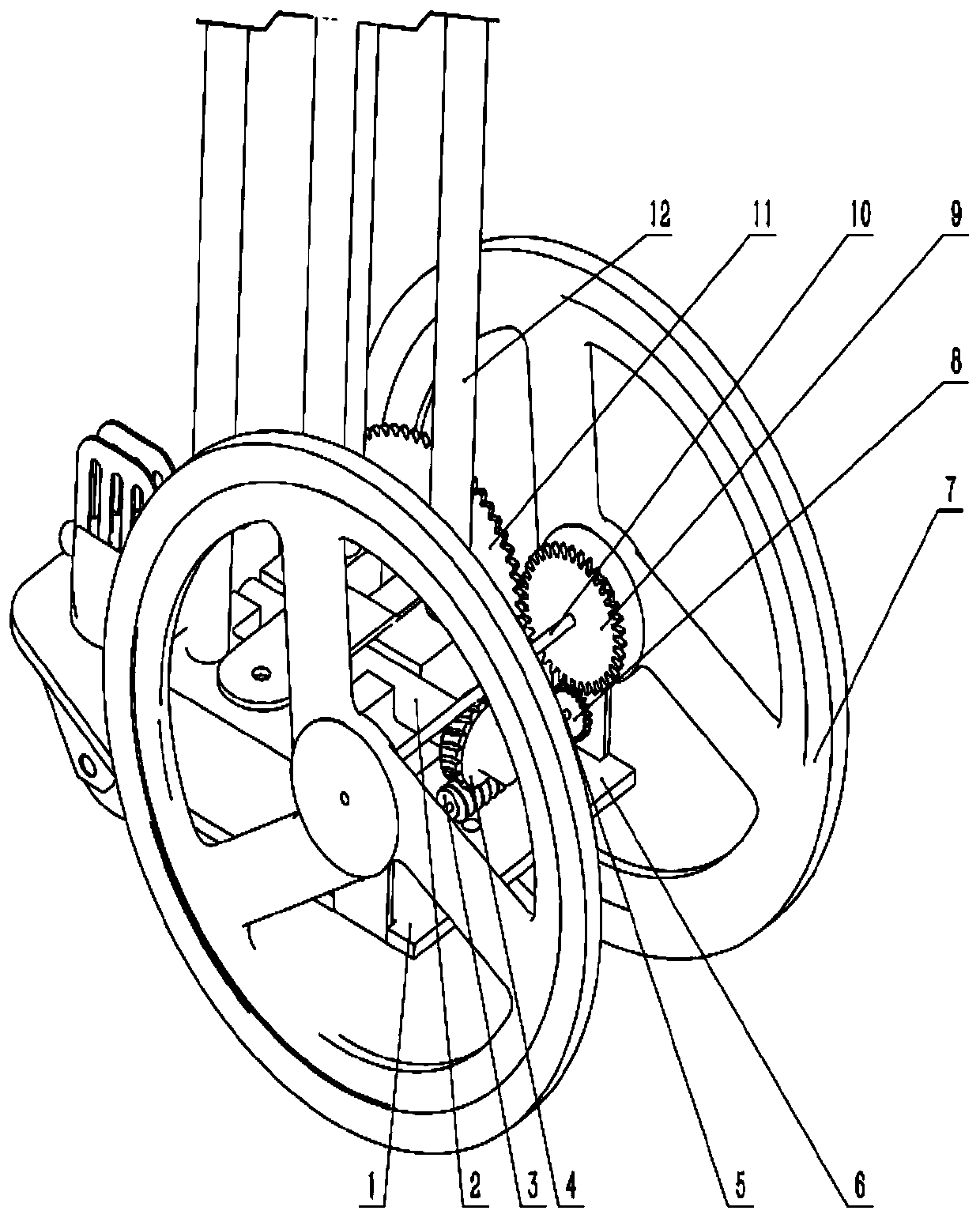

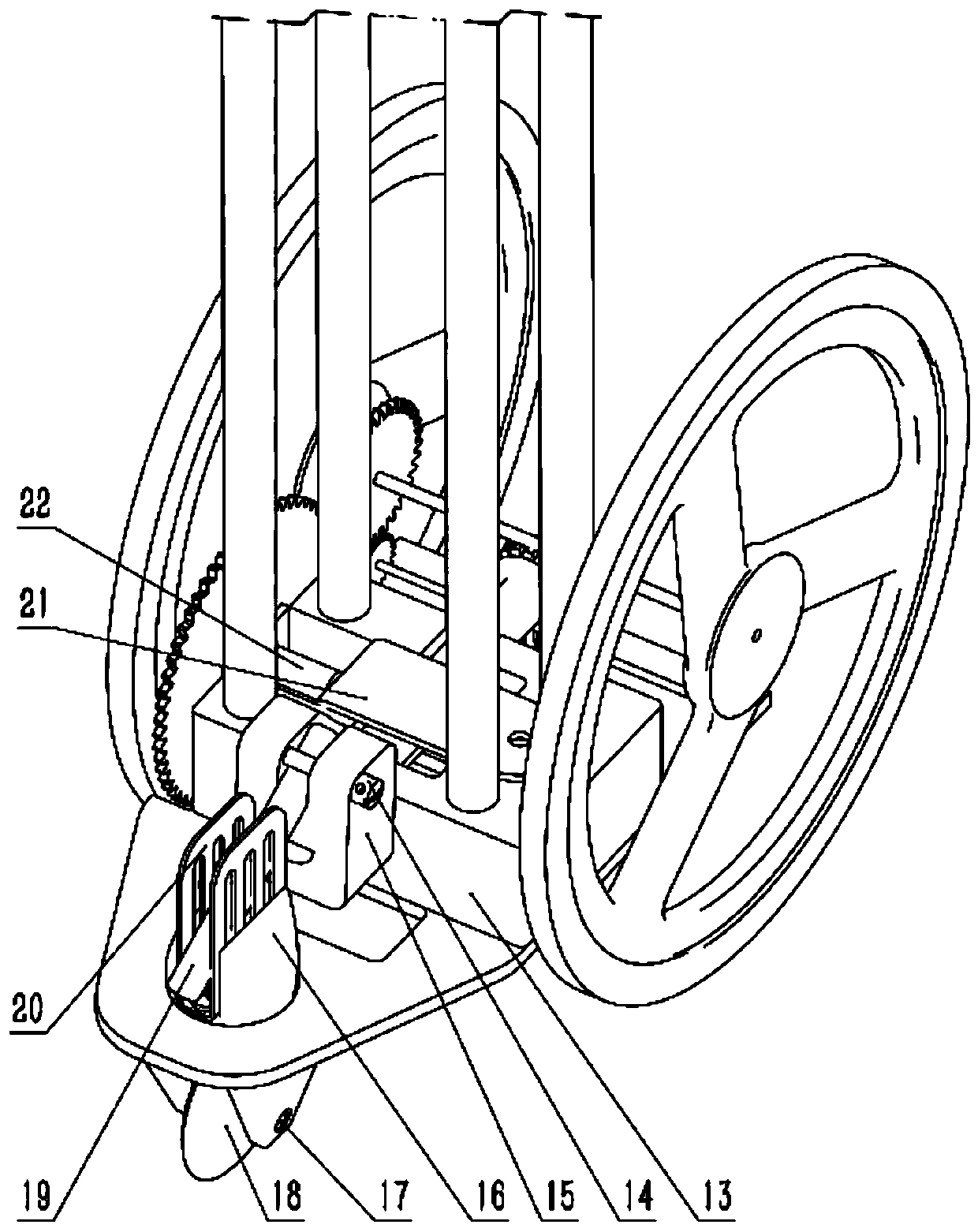

[0019] First, take out a rope, wind one end of the rope around the rope winding shaft 22, and tie the weight at the other end. When the weight falls freely from the top of the pole 12 by its own gravity, under the traction of the rope, the winding shaft 22 Do fixed axis rotation, which is the source of power.

[0020] Transmission gear set is made of large and small gears, and bull gear 11 is connected with bobbin shaft 22, and transmission pinion 9 is installed on rear axle 10, drives rear wheel 5,7. The specific action process is: the large gear 11 rotates on a fixed axis under the drive of the winding shaft 22. Since it is in mesh with the large gear 11, the transmission pinion 9 will rotate according to the transmission ratio and drive the rear axle 10 to rotate. The rear axle 10 and The trailing wheels 5 and 7 are connected, so the trailing wheels 5 and 7 can be driven, which is the working principle of the transmission mechanism driving the trailing wheels.

[0021] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com