Crankshaft type wine brewing grape vibration threshing device

A vibrating threshing and crankshaft technology, which is applied to harvesting machines, agricultural machinery and tools, and other applications, can solve the problems of manual harvesting difficulties, low threshing efficiency, and large plant damage, and achieve good toughness, improved threshing rate, and wear resistance powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

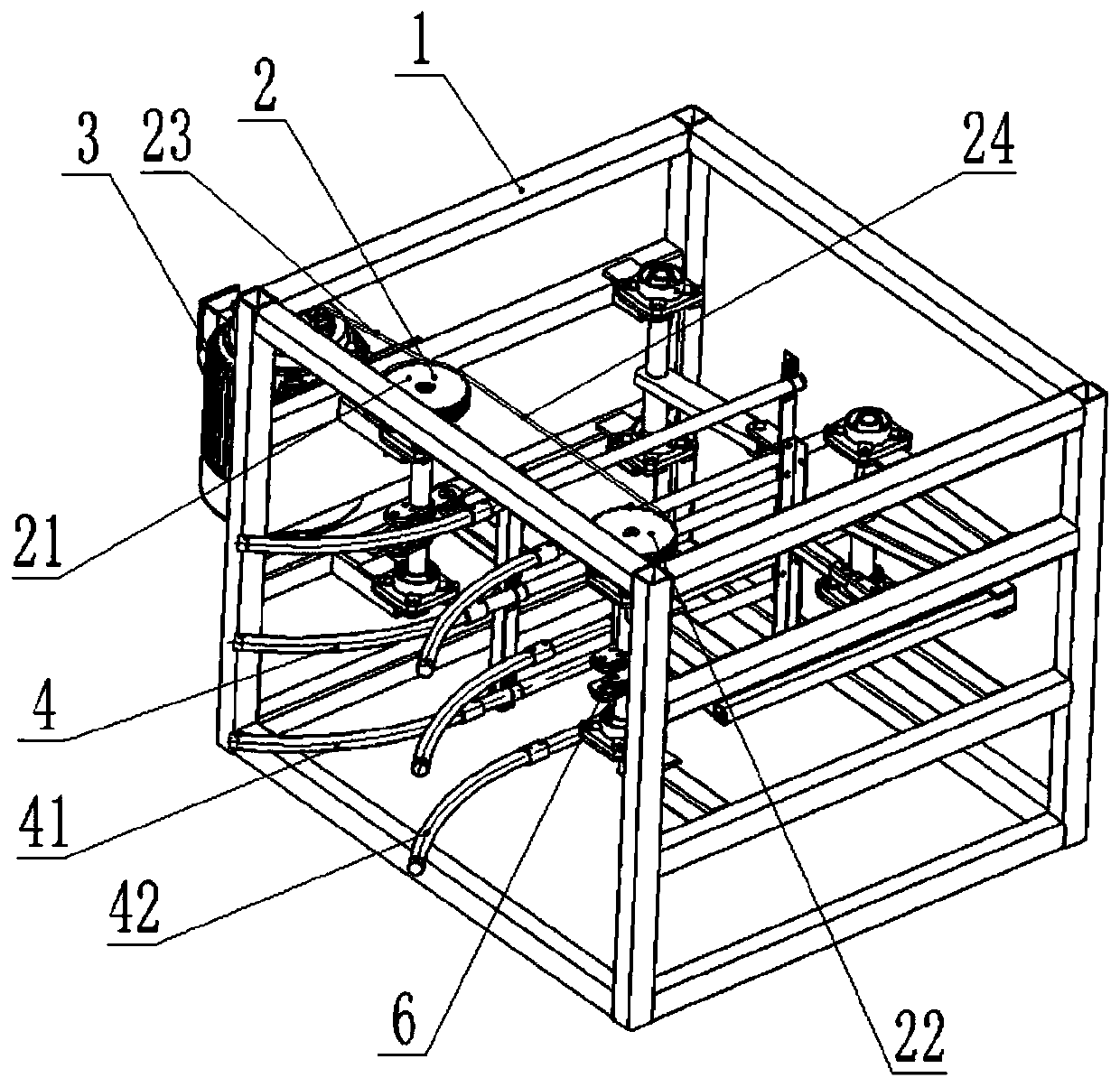

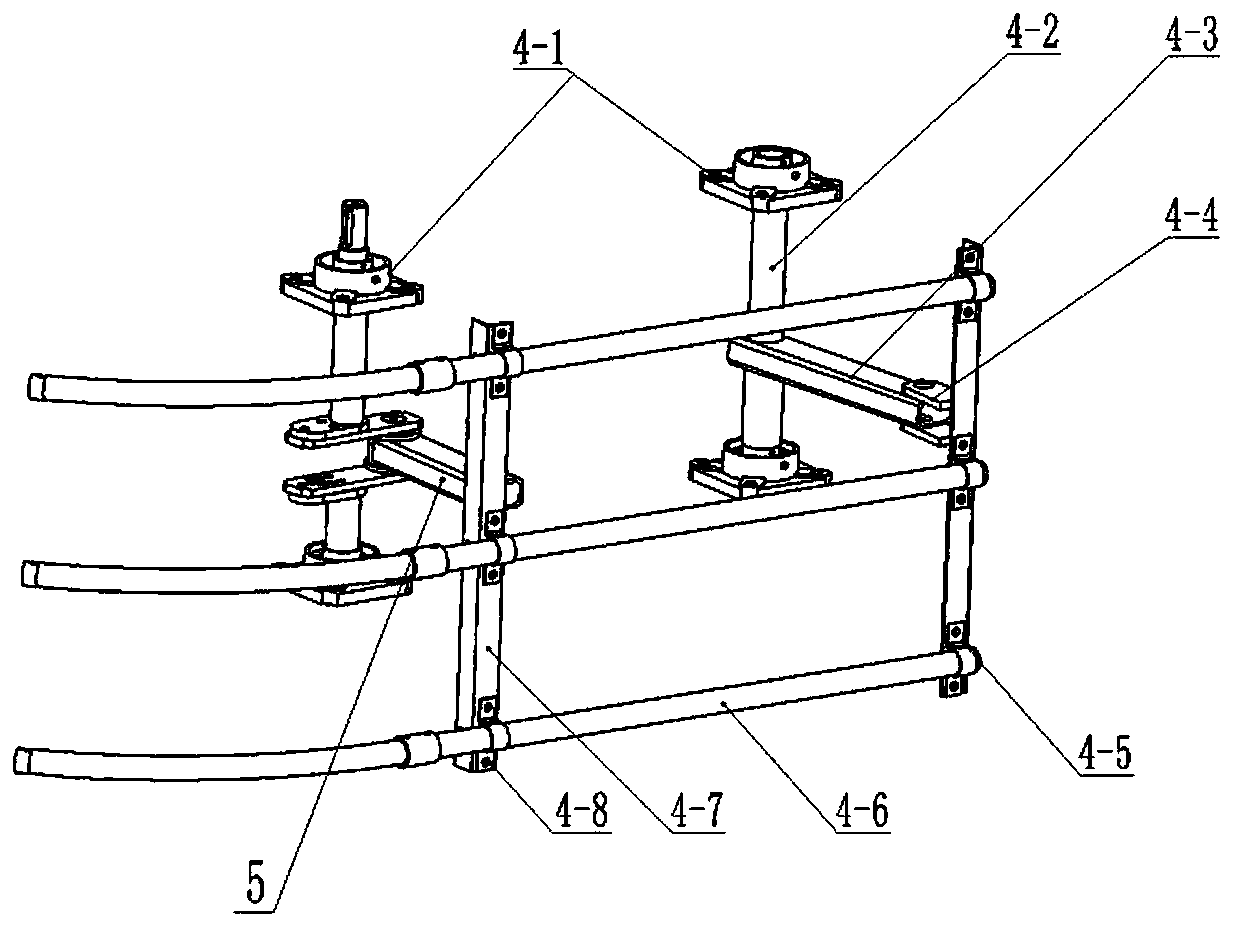

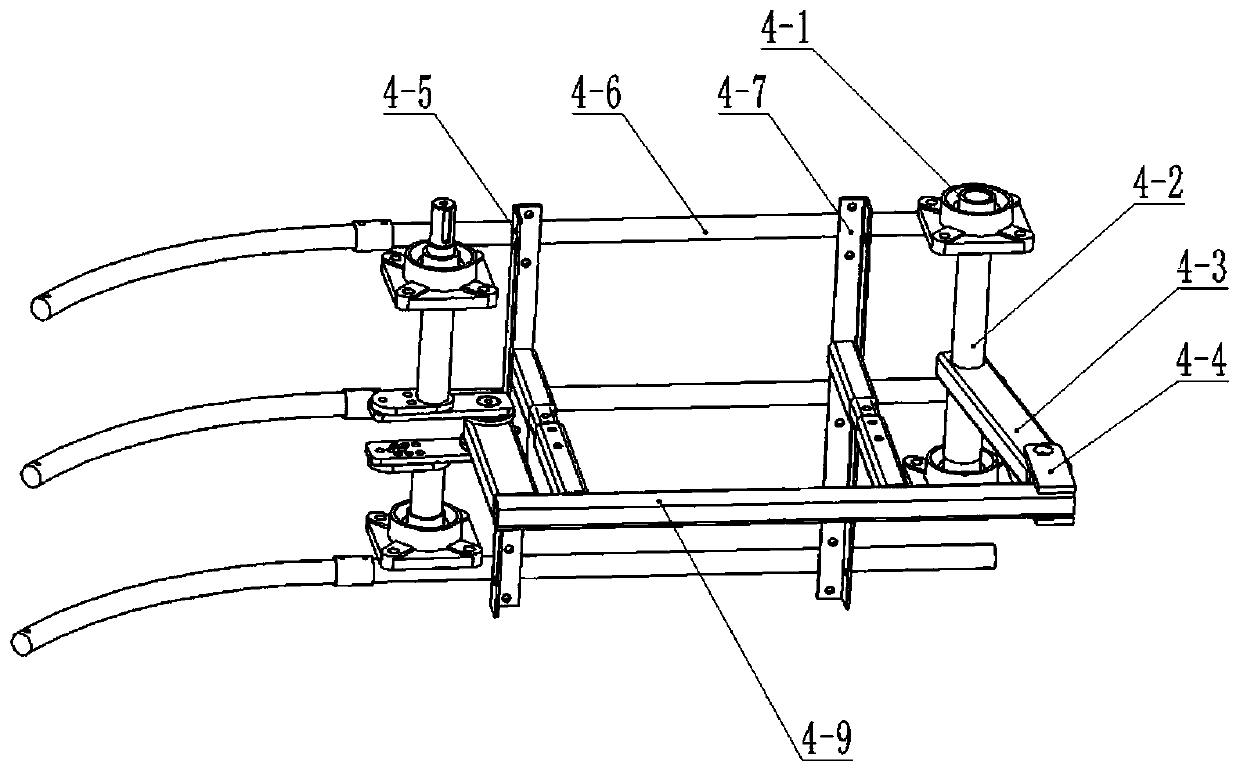

[0022] Such as figure 1 , 2 , 3, 4 and 5, a crankshaft-type vibrating threshing device for wine grapes, including a frame 1, a synchronous belt transmission system 2, a motor 3, an elastic clamping vibration mechanism assembly 4, a connecting rod 5 and a crankshaft 6, the The frame 1 is a welded structure made of steel profiles, and the synchronous belt drive system 2 includes a double-layer synchronous pulley 21, a synchronous pulley 22, a synchronous belt I 23 and a synchronous belt II 24, and the double-layer synchronous pulley 21 and the synchronous belt The pulleys 22 are fitted and fixed on the crankshaft 6 through hole shafts, and are connected with the output shaft of the motor 3 through the timing belt I23, and connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com