Oil peony fruit pod threshing and sorting device and process

A cleaning device and oil peony technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of easily damaged peony grains, low production efficiency, low threshing rate, etc., to increase the cleaning efficiency and the degree of mechanization. , Improve the effect of dirty air and working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

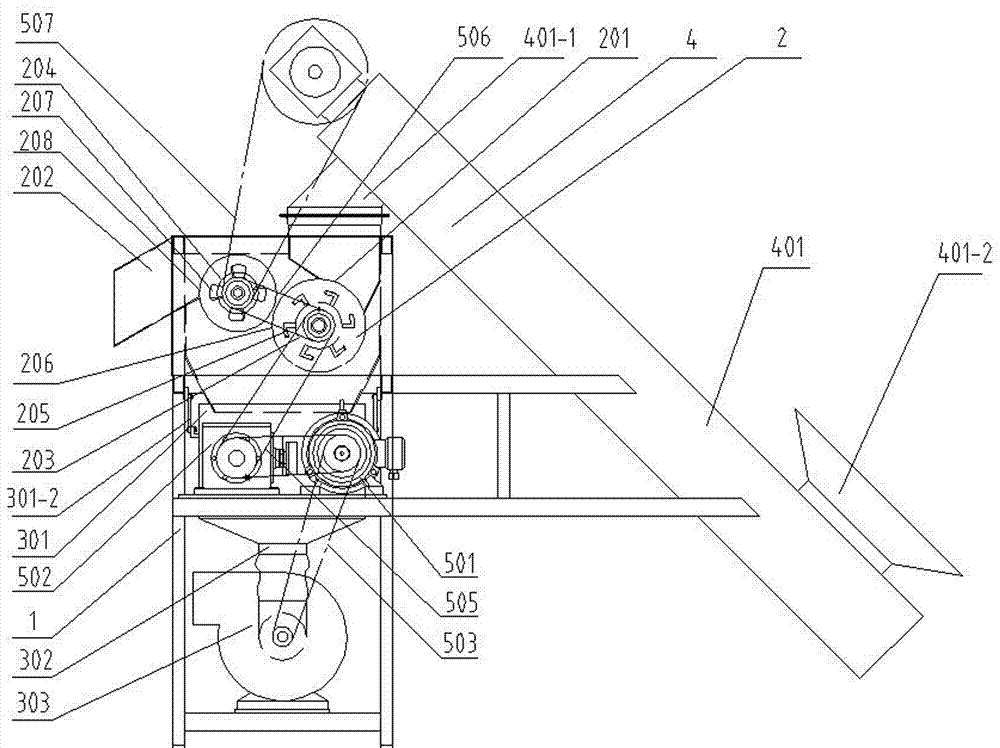

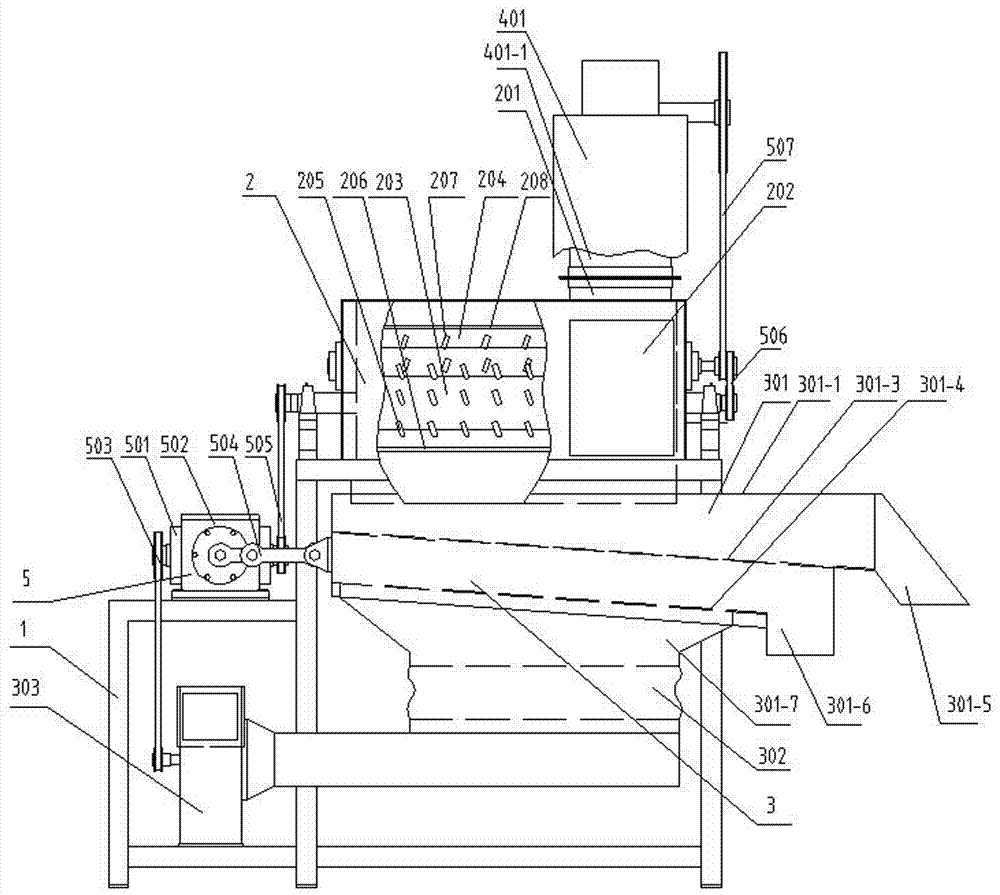

[0031] Such as Figure 1 to Figure 4 As shown, a kind of oil peony pod threshing and cleaning device of the present invention includes a frame 1 on which a step-by-step threshing system 2, a cleaning system 3, a feeding system 4 and a driving system 5 are arranged.

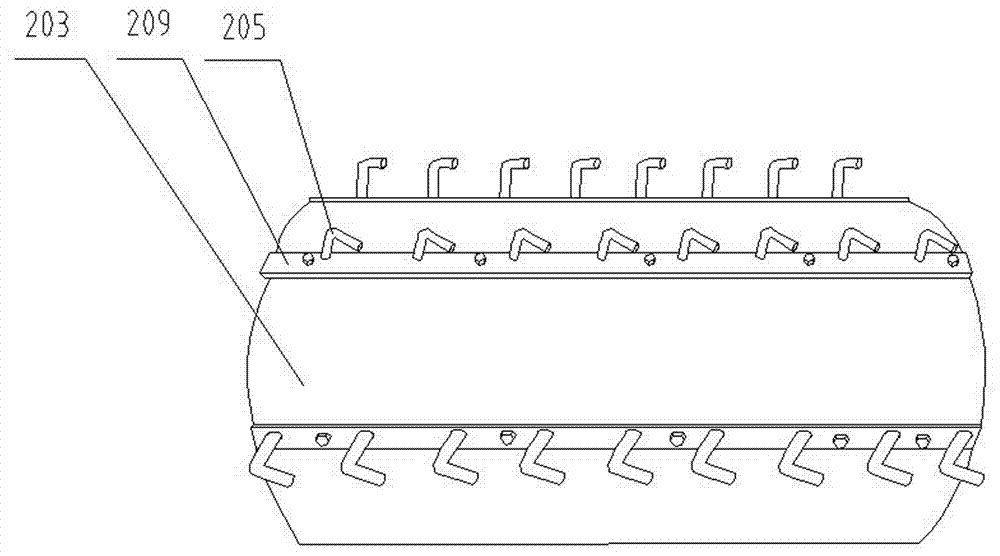

[0032] The step-by-step threshing system 2 includes a primary drum 203 and a secondary drum 204 horizontally arranged on the upper part of the frame 1, and the primary drum 203 and the secondary drum 204 are arranged in parallel. The outside of the primary cylinder 203 and the secondary cylinder 204 are coaxially sleeved with cylindrical screens fixed to the frame 1, which are respectively the primary cylindrical screen 206 and the secondary cylindrical screen 208, and the primary cylindrical screen 206 The sieve holes on the secondary cylindrical sieve 208 have the same aperture, and the sieve holes are evenly spaced at the lower part of the primary cylindrical sieve 206 and the secondary cylindrical sieve 208 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com