Pipe hole cutting device for simple type metal pipe fitness

A technology for cutting devices and metal pipe fittings, applied in metal processing equipment, welding equipment, plasma welding equipment, etc., can solve the problems of no economic value, high purchase cost, large floor space, etc., achieve simple structure, expand the scope of use, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

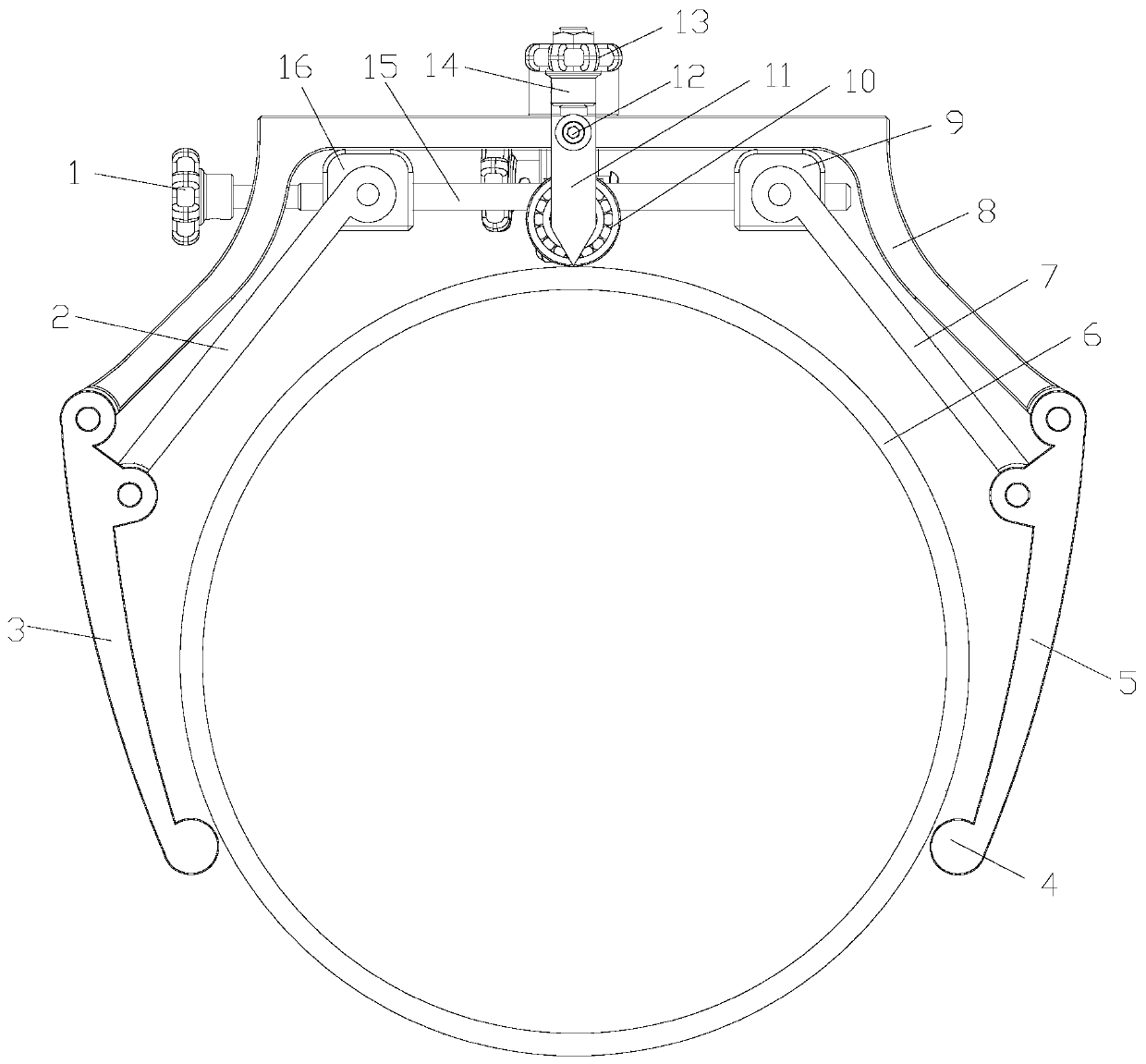

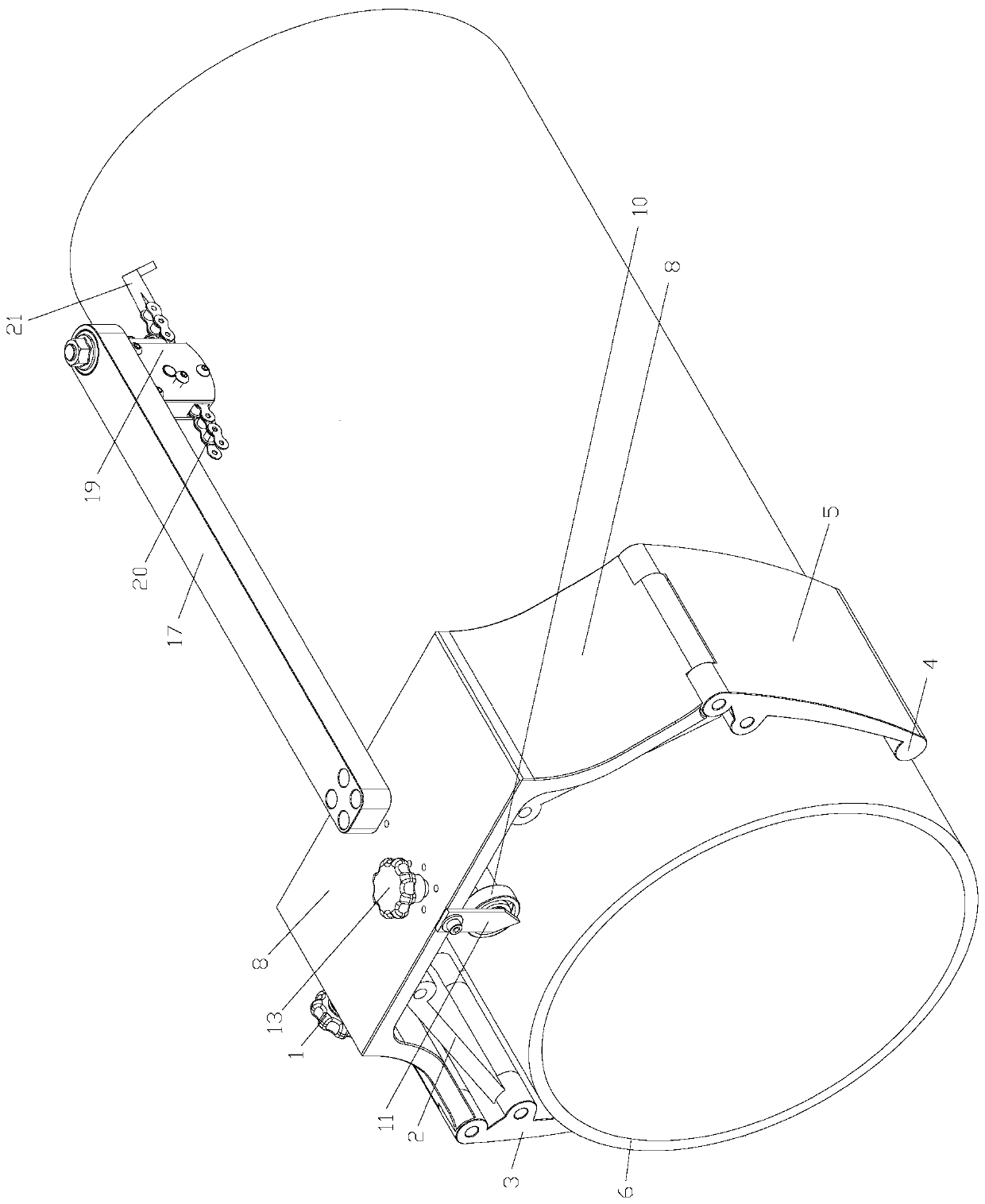

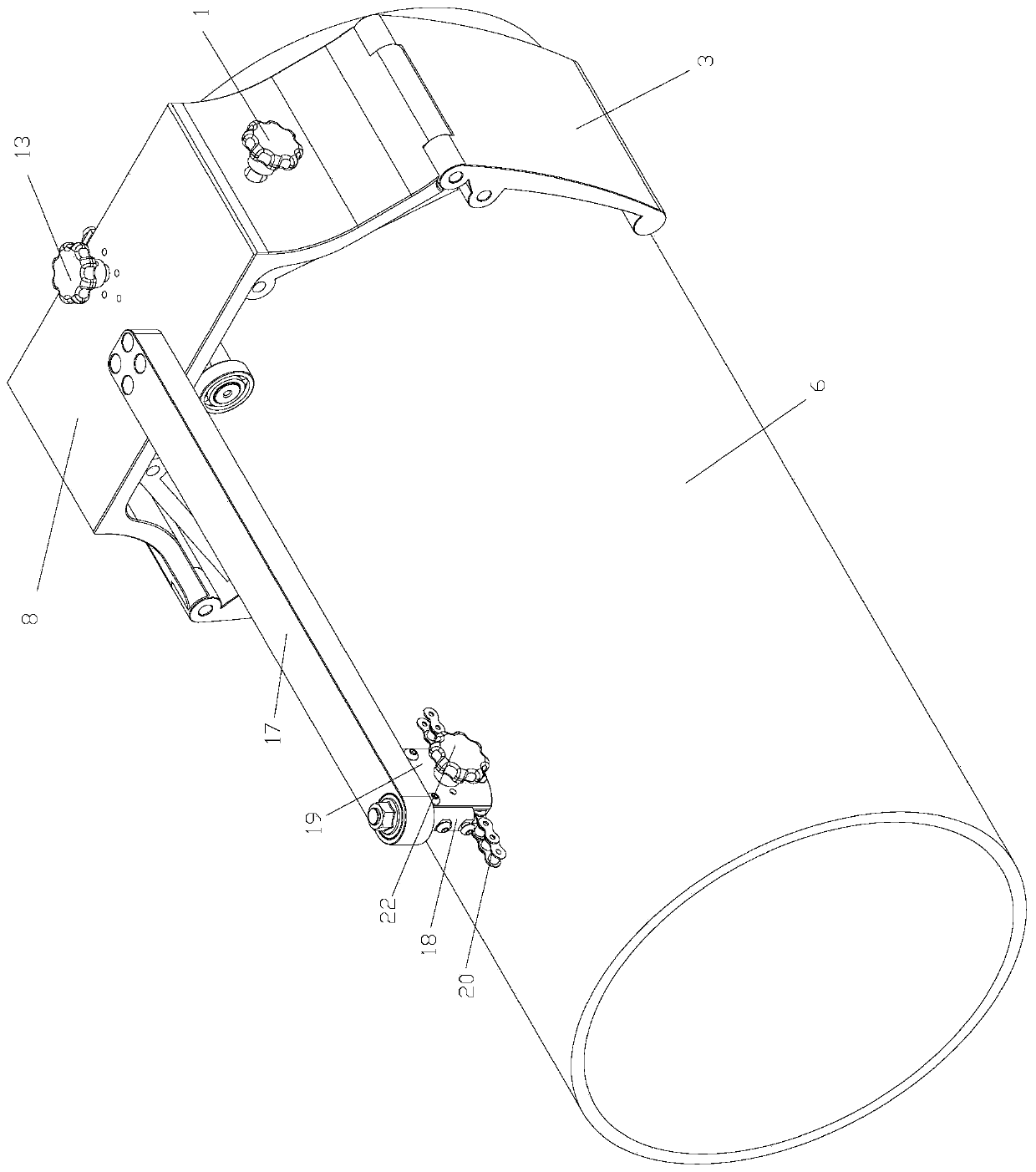

[0024] Example: such as Figure 1-3 As shown, a simple metal pipe fitting pipe hole cutting device includes a positioning device for positioning and installing a workpiece 6 and a cutting device for processing holes. The left clamping plate 3 and the right clamping plate 5 at the lower ends of the two sides of the positioning frame 8 and the left slide plate 2 and the right slide plate 9 whose lower ends are hingedly connected with the left clamping plate 3 and the right clamping plate 5 respectively, the left slide plate 2 and the right slide plate 9 The upper ends of the right slide plate 9 are all slidably mounted on the positioning frame 8, and the positioning frame 8 is provided with the upper end for driving the left slide plate 2 and the upper end of the right slide plate 9 to slide towards each other synchronously or slide backward to drive the left clamping plate 3 and the right clamping plate 5. A driving device for rotating and clamping the workpiece 6. The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com