A notoginseng stalk harvester

A harvester and stalk technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., to achieve the effect of light body, convenient maintenance, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

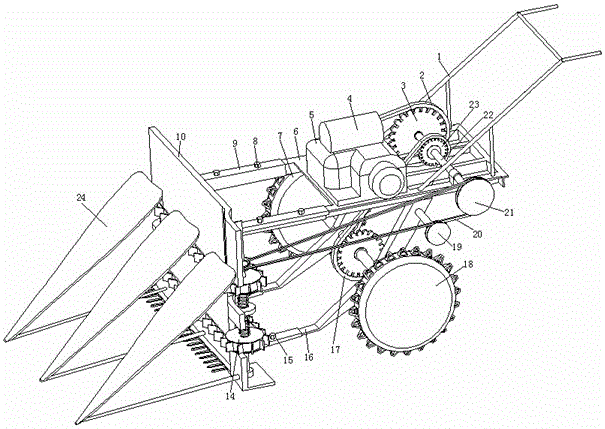

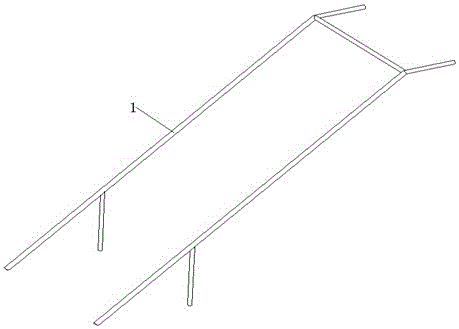

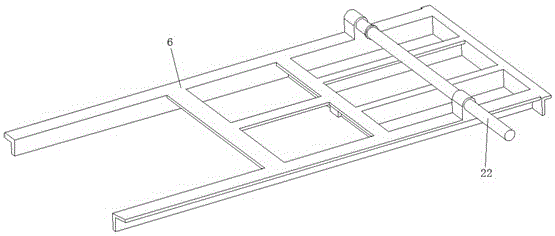

[0039] Embodiment 1: as Figure 1-15 As shown, a notoginseng stalk harvester includes handrail 1, chain 2, sprocket I3, fuel tank 4, engine 5, frame 6, right wheel 7, upper adjustment nut 8, adjustment arm 9, front baffle 10 , Upper reel 11, lower reel 12, harvesting knife 13, lower left drive wheel 14, lower adjustment nut 15, wheel bracket 16, sprocket II 17, left wheel 18, lower pulley 19, belt 20, upper pulley 21, Upper pulley shaft 22, sprocket III 23, grain divider 24, front baffle bracket 25, wheel shaft 26, lower pulley shaft 27, right lower drive wheel 28, spring 29, right upper drive wheel 30, cutting drive shaft 31, left upload Moving wheel 32 and cam 33;

[0040] The handrail 1 and the upper pulley shaft 22 are installed on one end of the vehicle frame 6, one end of the upper pulley shaft 22 is provided with a sprocket I3, the middle part is provided with a sprocket III 23, and the other end is provided with an upper pulley 21; the fuel tank 4 is installed on the ...

Embodiment 2

[0046] Embodiment 2: basically similar to Embodiment 1, its difference is:

[0047] The handrail 1 is a hollow pipe, and the vehicle frame 6 and the front baffle bracket 25 are formed by welding angle steel.

[0048] The plate and the surface of the belt form an angle of 45°, and the material of the plate is a rubber plate.

Embodiment 3

[0049] Embodiment 3: as Figure 1-15 As shown, a notoginseng stalk harvester includes handrail 1, chain 2, sprocket I3, fuel tank 4, engine 5, frame 6, right wheel 7, upper adjustment nut 8, adjustment arm 9, front baffle 10 , Upper reel 11, lower reel 12, harvesting knife 13, lower left drive wheel 14, lower adjustment nut 15, wheel bracket 16, sprocket II 17, left wheel 18, lower pulley 19, belt 20, upper pulley 21, Upper pulley shaft 22, sprocket III 23, grain divider 24, front baffle bracket 25, wheel shaft 26, lower pulley shaft 27, right lower drive wheel 28, spring 29, right upper drive wheel 30, cutting drive shaft 31, left upload Moving wheel 32 and cam 33;

[0050] The handrail 1 and the upper pulley shaft 22 are installed on one end of the vehicle frame 6, one end of the upper pulley shaft 22 is provided with a sprocket I3, the middle part is provided with a sprocket III 23, and the other end is provided with an upper pulley 21; the fuel tank 4 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com