Dust removal device for calcining cokeand dust removal method thereof

A technology of dust removal device and coke, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., can solve the problems of low dust removal efficiency, small filtration area, environmental impact, etc., achieve improved dust removal effect, increase dust removal area, and facilitate maintenance and the effect of replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

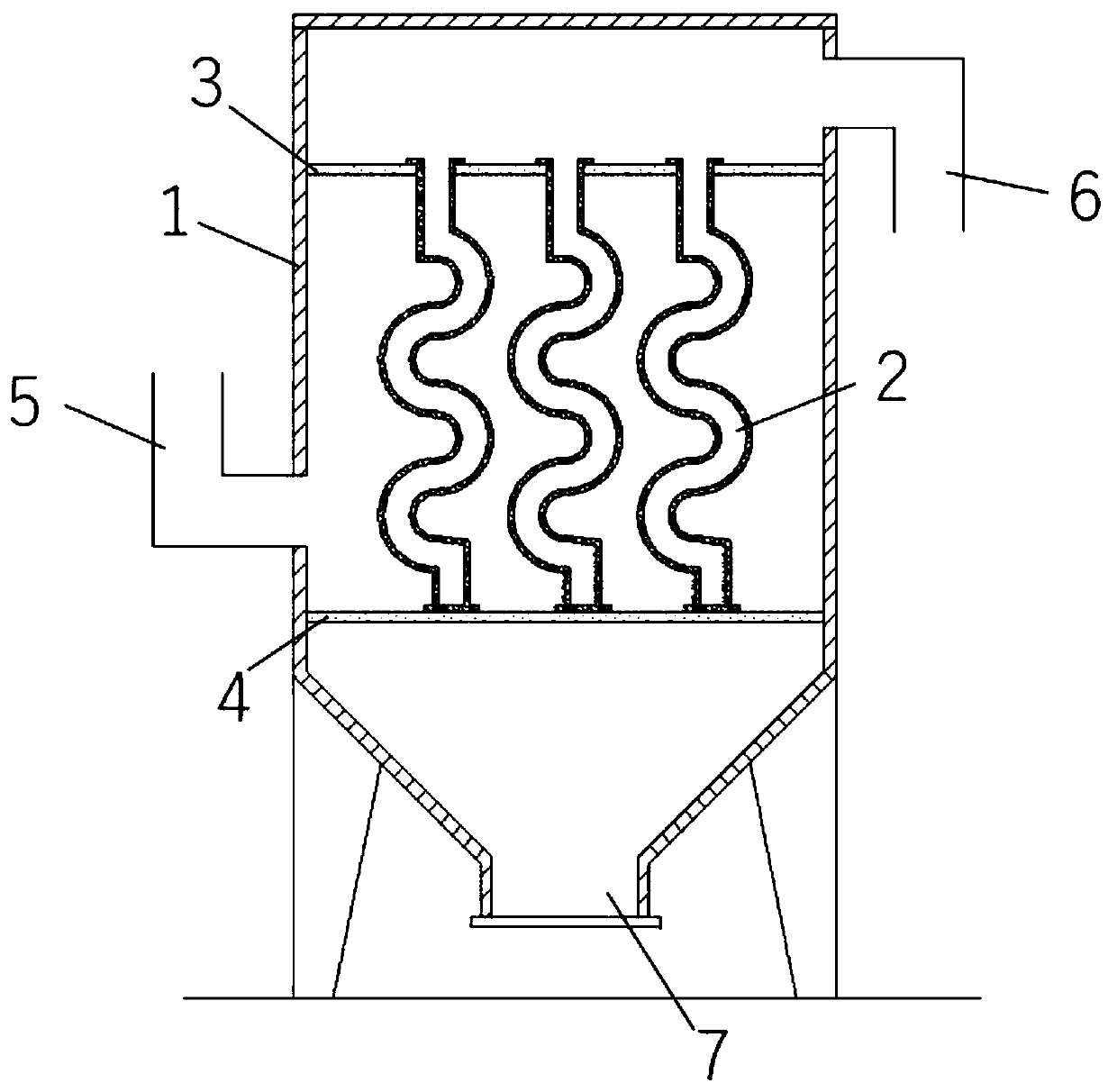

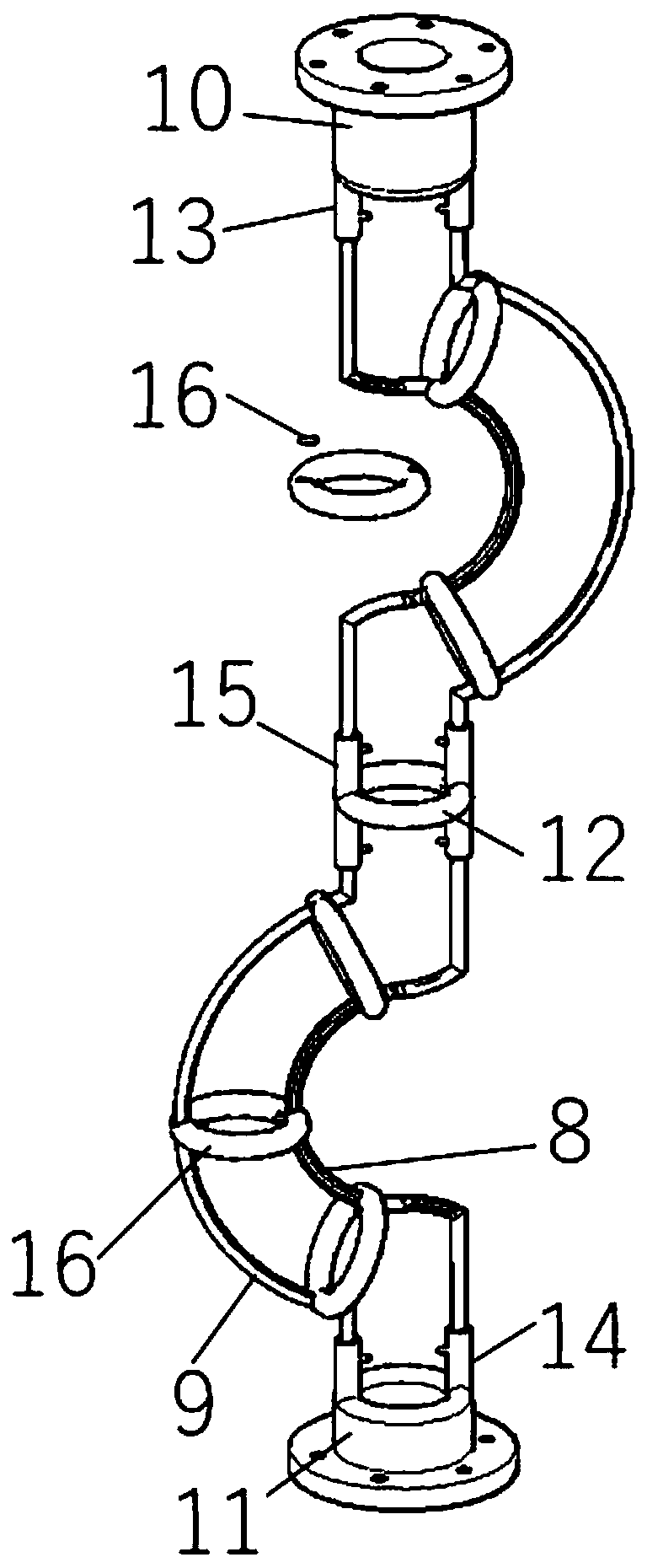

[0027] Such as Figure 1 to Figure 2 As shown, a dust removal device for calcined coke and a dust removal method thereof include a dust removal box 1 and a dust removal bag, the lower end of the dust removal box 1 is provided with a dust outlet 7, and the dust outlet 7 is located in the dust removal box 1 The second partition 4 and the first partition 3 are arranged in sequence above; the top of the first partition 3 is located on the side of the dust removal box 1 and an outlet 6 is provided; between the first partition 3 and the second partition 4 An inlet 5 is provided on the other side of the dust removal box 1; several dust removal bags are arranged between the first partition 3 and the second partition 4, and a skeleton 2 is arranged inside the dust removal bag; the skeleton 2 is integrally It is S-shaped, the dust removal bag is set on the periphery of the skeleton 2, and fits the outline of the skeleton 2; through the S structure, the dust removal area of the dust re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com