A bag filter dust removal device

A bag-type dust collector and ash cleaning device technology, applied in chemical instruments and methods, separation methods, climate sustainability, etc., can solve the problems of increased investment cost, insufficient space layout, and many blowing pipes, etc., and increase the dust removal area. , The effect of reducing equipment investment and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

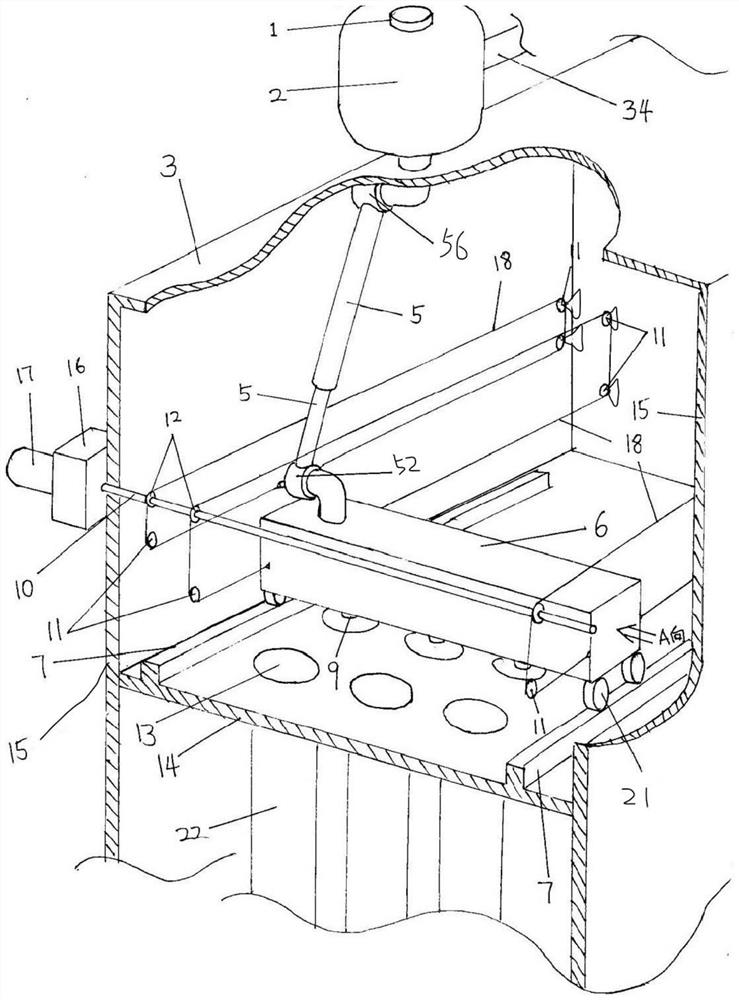

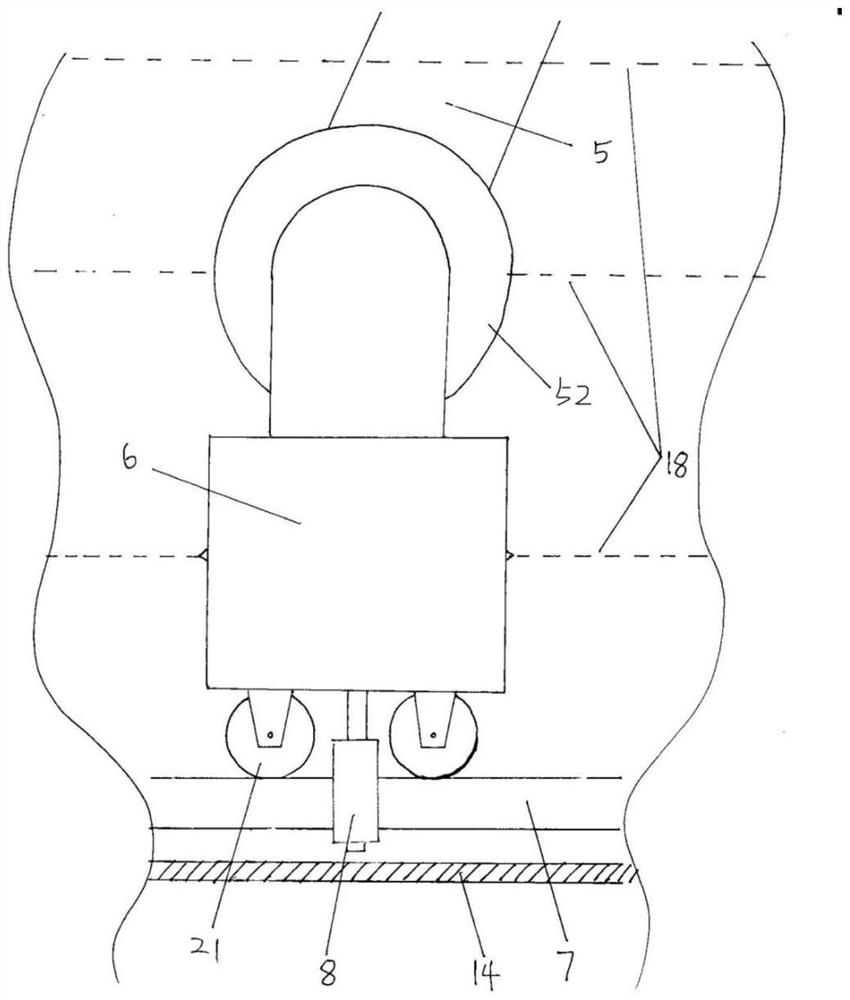

[0107] Such as figure 1 As shown, the side plate 15 of the clean air chamber, the flower plate 14, and the top plate 3 of the clean air chamber jointly constitute the clean air chamber of the bag filter. Outside the top surface of the clean air chamber and fixed on the top plate 3 of the clean air chamber and its structural beams, an air bag 2 is provided, which is connected to the Roots blower through the air bag inlet pipe 34 . The gas bag 2 is equipped with a pulse valve 1, and the pipeline connected to the outlet of the pulse valve 1 passes through the top plate 3 and enters the clean gas chamber to become horizontal, and connects the swivel joint 56 in the horizontal section, and then connects the gas delivery pipe 5. Air pipe 5 is the telescoping tube that is moved and matched suit by big and small two section tubes. The lower casing of the air pipe is connected to a rotary joint 52, which is connected to the end of the blowing pipe 6. The bottom of the blowing pipe 6 ...

Embodiment 2

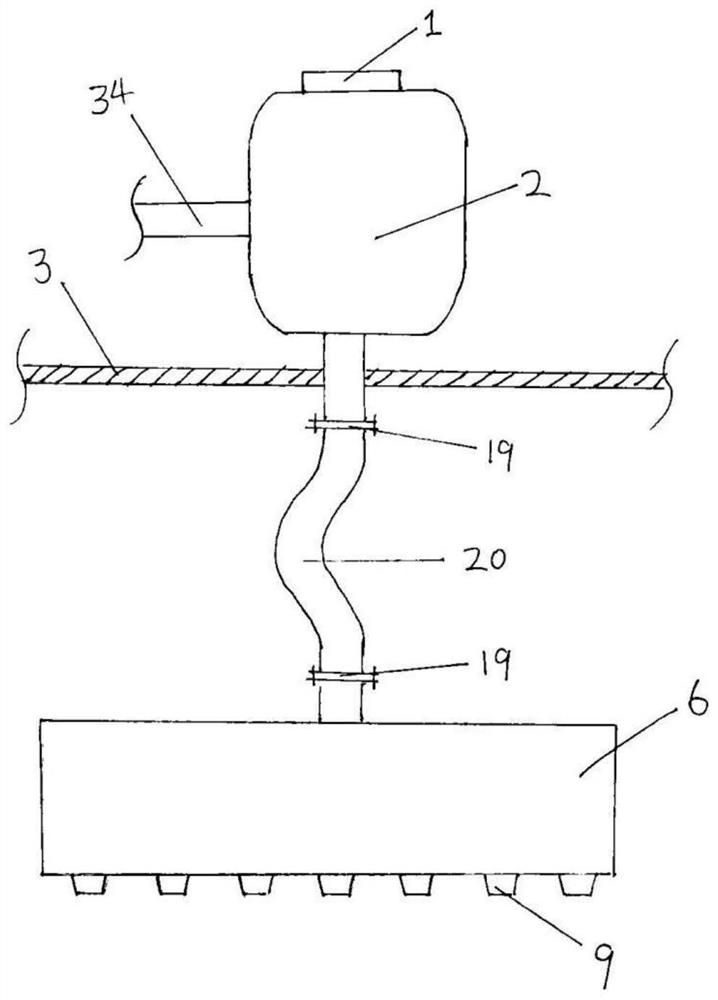

[0113] Such as figure 2 As shown, the difference from Embodiment 1 is that the pipeline connected to the outlet of the pulse valve 1 passes through the top plate 3 and enters the clean air chamber, and then connects with the flange 19 at one end of the flexible gas transportation hose 20 . The other flange 19 of the gas delivery hose 20 is connected to the end of the blowing pipe 6, and the pulse gas is introduced into the blowing pipe 6 and sprayed into the quasi-elliptical filter bag mouth 23 through the nozzle 9 to remove the filter bag 22. Dust accumulation on exterior surfaces.

[0114] Another difference from Embodiment 1 is that, as Figure 17 As shown, a brake line working end is provided above the pocket cover supporting plate 25, and the working end drives a lever-type mechanism 33 for relying on the steel wire of the brake line core, and the lever mechanism relies on spring force to keep the Fixed posture. When operating the operating end of the brake wire 28, t...

Embodiment 3

[0117] exist figure 1 Basically, the blowing pipe is also provided with a wind blocking baffle.

[0118] Figure 4 It is a schematic diagram of one side of the connection between the wind blocking cover plate 35 and the blowing pipe 6 , and the connection relationship on the other side is consistent with the connection relationship on this side.

[0119] Such as Figure 4 As shown, the wind blocking cover plate 35 is provided with a lifting guide rail 36, and the blowing pipe 6 is provided with a cover plate lifting guide wheel 37, and the lifting guide rail 36 moves up and down outside the cover plate lifting guide wheel 37, and the lifting guide rail 36 and the cover plate lifting guide wheel The connecting device that wheel 37 forms connects wind-blocking cover plate 35 with blowing pipe 6 . Both sides of the wind-blocking cover plate 35 are provided with lifting rollers 45, and the lifting rollers 45 are on the wind-blocking cover plate track 46 (see Figure 5 ), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com