A temperature uniformity detection device for a conveyor belt vulcanizer

A detection device and a vulcanizing machine technology, which is applied in the field of temperature measurement, can solve the problems that cannot truly reflect the uniformity of the hot plate of the vulcanizing machine, cannot truly reflect the real working conditions of the closed space of the vulcanizing machine, and the hot plate of the vulcanizing machine is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

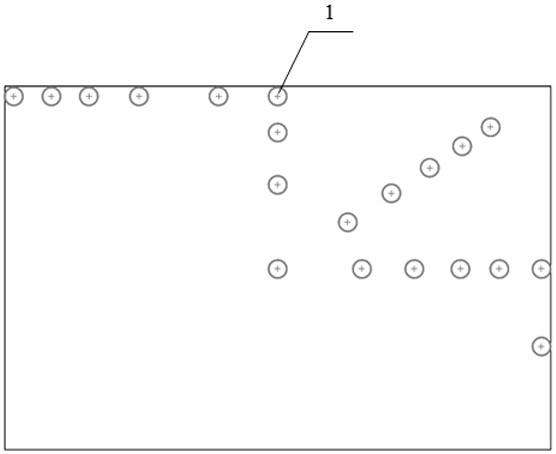

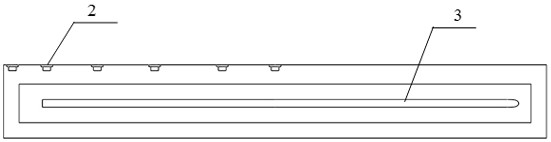

[0021] like figure 1 , 2 As shown, the present invention provides a temperature uniformity detection device for a conveyor belt vulcanizer, including a steel plate, a temperature sensor, a single-chip computer, a cooling water pipe, a spring, and a computer.

[0022] The steel plate is an assembled hollow structure, which is used to install a cooling pipeline inside, and a pressurizing device is connected to the outside, which accelerates the flow of cooling water and reduces the temperature more quickly;

[0023] The surface of the steel plate is provided with a countersunk hole. The upper part of the countersunk hole is used to install a temperature sensor, and the lower part is installed with a spring. The temperature sensor is completely fitted with the surface of the vulcanizer hot plate under the action of the spring elastic force. The countersunk hole is based on simulation and experimentation. The measured temperature cloud map of the surface of the hot plate is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com