Circuit layout construction for measuring whether concave falls are generated by copper wire

A technology of layout structure and copper wires, which is applied in the direction of circuits, electrical components, and electrical solid devices, and can solve problems such as complex testing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

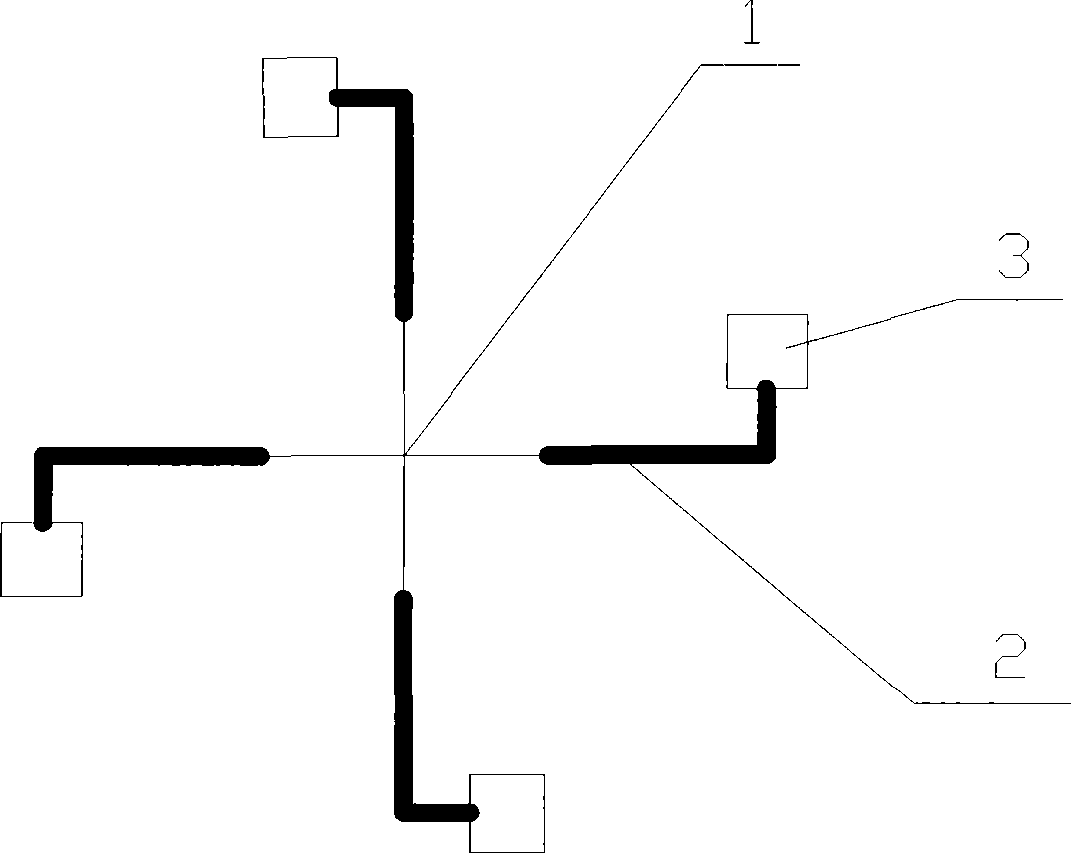

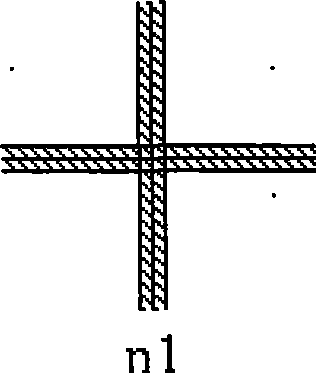

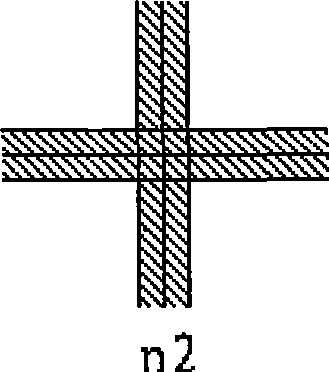

[0016] The present invention is a layout structure for testing concave pits of copper leads by an electrical testing method. The layout structure includes a set of independent copper lead cross unit arrays, and the independent cross unit array is composed of at least two mutually independent cross units. ,Such as figure 1 As shown, each independent cross unit is composed of copper leads 1 of equi-arm cross structure. The copper leads of each independent cross unit have four output terminals 2 . The copper lead groove depth of each independent cross unit is the same. The copper lead line width of each individual cross unit is different. Such as diagram 2-1 , Figure 2-2 with Figure 2-3 As shown, the independent cross unit array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com