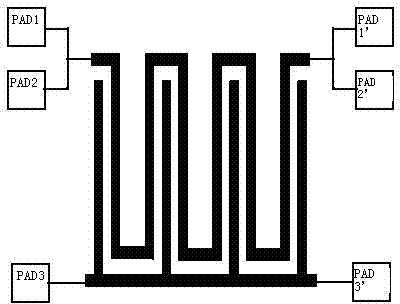

Circuit layout structure for detecting dishing on copper interconnect lines

A technology of layout structure and interconnection line, applied in material capacitance, electromagnetic measurement device, electric/magnetic depth measurement, etc., can solve the problems of general lateral resolution, complicated operation, wafer surface damage, etc. The experimental measurement is convenient to verify the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: The copper wire of the bending structure is a four-terminal structure, and its resistance value can be accurately measured by the Kelvin method; at the same time, PAD1, PAD1', PAD2, and PAD2' are placed at low or high levels, When PAD3 and PAD3' are placed at opposite levels, the capacitance value of the comb structure can be measured.

[0013] Comb-tooth structure capacitance value measured by The groove depth of the copper wire can be calculated according to formula (1), where represents the groove depth, is the vacuum permittivity, is the dielectric constant of the low-K medium, is the distance between the Cu meander line and the Cu comb line, is the length of the Cu meander.

[0014] Formula 1)

[0015] Therefore, the resistance value of the copper meandering wire can be further calculated by formula (2), where Indicates the copper meander resistance, is the resistivity of Cu, is the length of the Cu meander, is the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com