Wood transferring device

A wood, No. 1 technology, applied in the field of wood transfer devices, can solve problems such as high cost, and achieve the effects of reducing the strength of the material, easy to adjust, easy to transfer and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

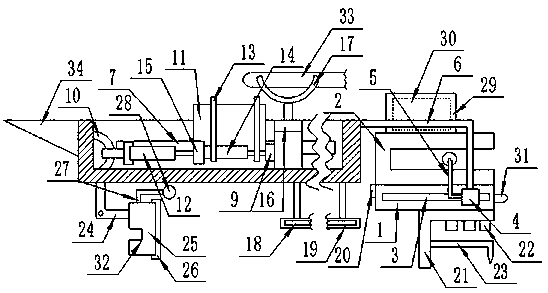

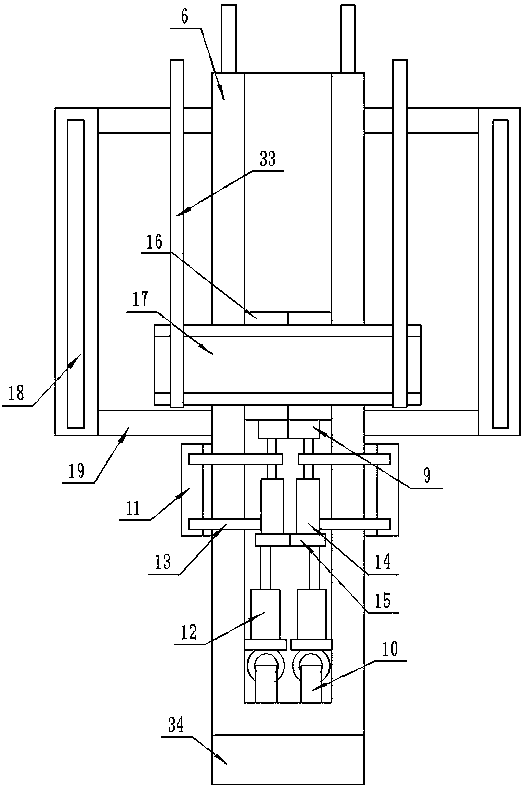

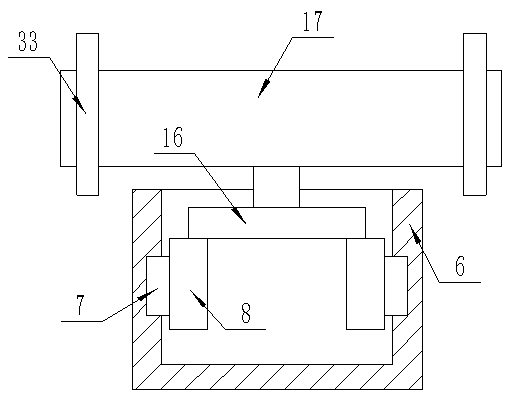

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a kind of wood transfer device comprises a strip support base 1, the upper surface of the strip support base 1 is provided with an intelligent wood transfer mechanism, and the lower surface of the strip support base 1 is provided with a fixing mechanism, so The intelligent wood transfer mechanism is composed of an inverted U-shaped support block 2 fixedly connected to the upper surface of the strip-shaped support base 1, a group of horizontal slides 3 embedded in the front and rear surfaces of the strip-shaped support base 1, and arranged on each level. The sliding block 4 in the slideway 3, the sliding limit rod 5 fixedly connected to the side surface of a group of sliding blocks 4 and overlapping with the inside of the inverted U-shaped support block 2, and the swing of the upper surface of a group of sliding blocks 4 connected by hinges Support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com