A Realization Method of Sectional Temporary Prestress of Bridge Segment

A realization method and prestressing technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low pressure at the lower end, high pressure at the upper end of the joint, and inability to achieve uniform pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

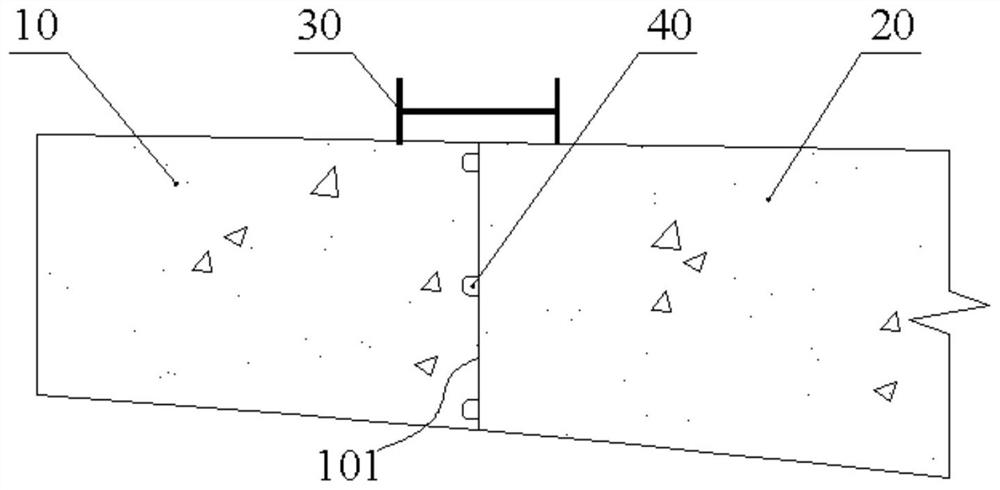

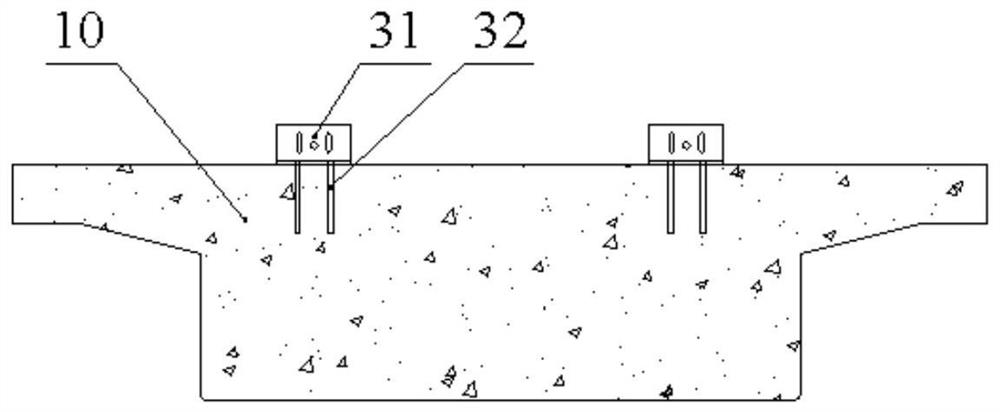

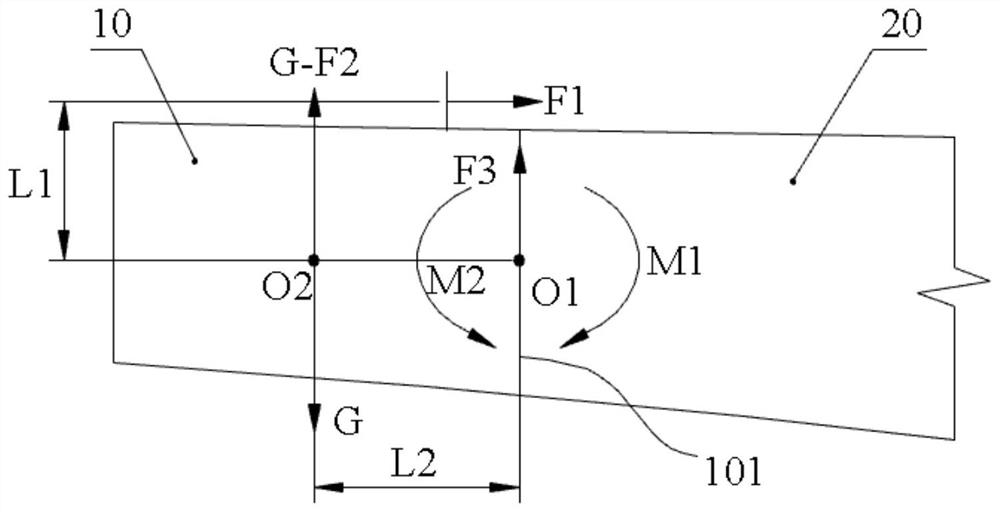

[0029] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0030] In the prior art, for variable-section bridges with vertical curves, when the height of the cavity in the segment cannot meet the operating conditions or there is no cavity, in order to achieve the extrusion force required by the glued joint, it must be placed at the bottom of the beam. Set up temporary prestressing devices. However, due to the large difference in beam height between adjacent segments, or when the bridge crosses existing roads, railways, and municipal roads, the way to install temporary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com