Liquid nitrogen freezing device with freezing pipe provided with partition plate and construction method

A technology of freezing tubes and freezers, which is applied in basic structure engineering, soil protection, construction, etc., and can solve the problems that the development of frozen soil cannot be accurately controlled, the control is difficult, and the uniformity of the frozen wall is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

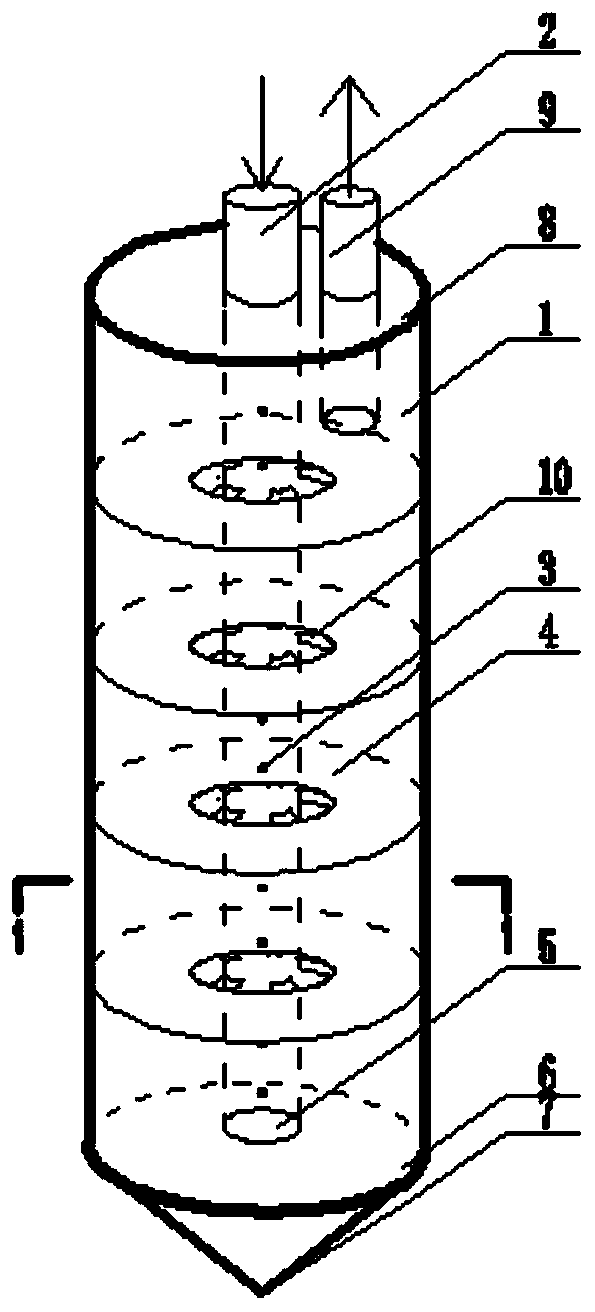

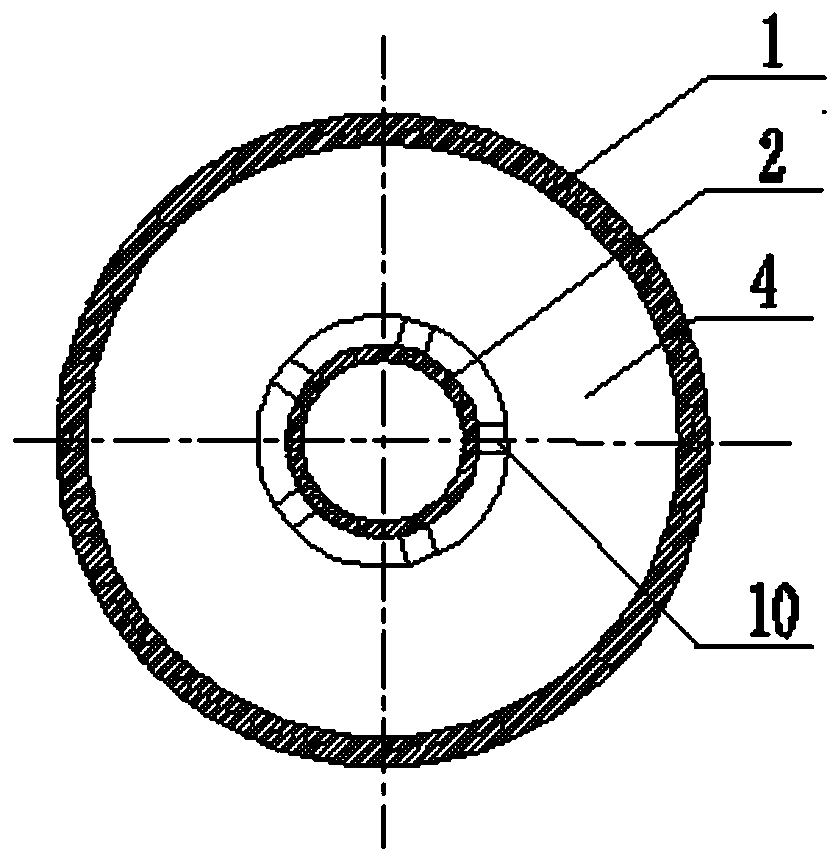

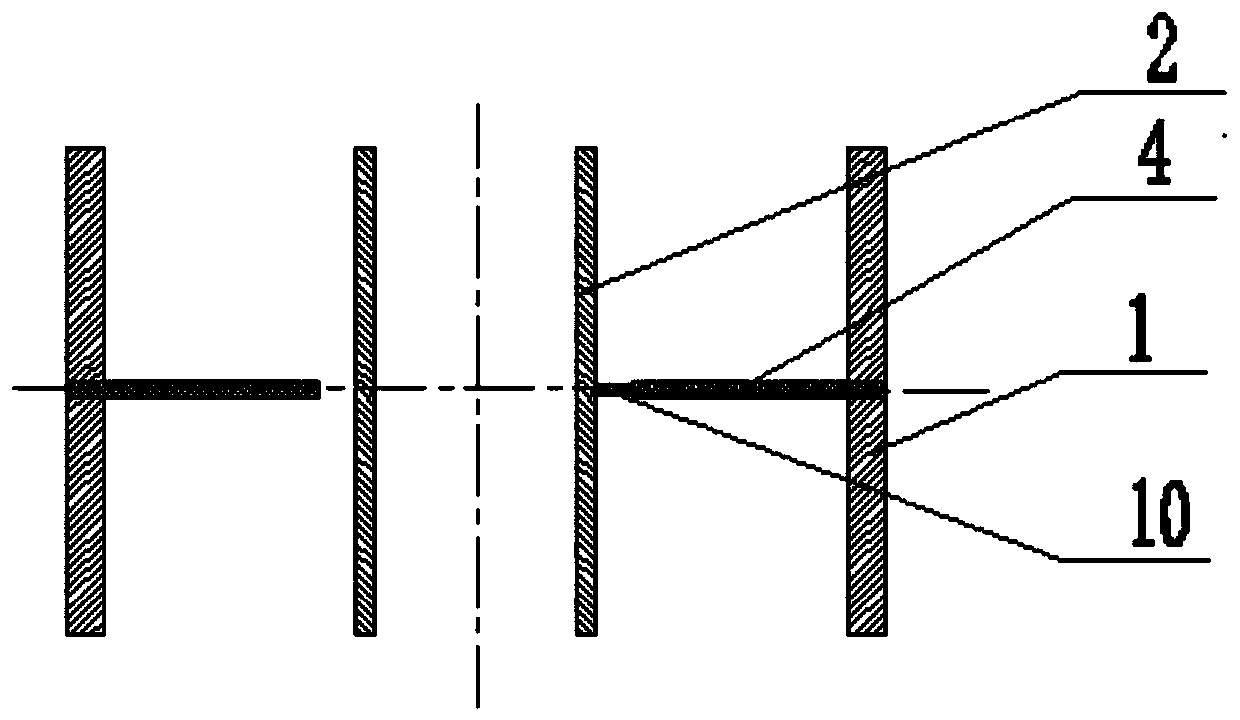

[0033] The first step is to measure the depth range of the bottom layer that needs to be frozen according to the needs of actual construction. According to the measurement situation, open spray holes 3 along the direction of the freezing pipe 1 where holes need to be opened. Five spring supports 10 are welded at the inner edge of the plate, and the upper and lower sides of the circular dividing plate 4 are welded with the freezing tubes 1 at both ends to form the joints where the dividing plate is in the middle and freezing the tubes 1 on both sides. According to the needs of freezing depth during construction, joints with partitions are welded at different positions of the freezing tube 1 to form liquid nitrogen freezing tubes 1 with different partition intervals;

[0034] In the second step, use the plugging 5 to block one end of the liquid supply pipe, and insert the liquid supply pipe along the spring support 10 on the dividing plate into the freezing pipe with the end that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com