Snowflake machine roller

A technology of snowflake machine and roller, which is applied in ice making, lighting and heating equipment, leisure ice making, etc. It can solve unresolved technical problems and other problems, and achieve the effect of reasonable design, improved condensation effect and consistent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

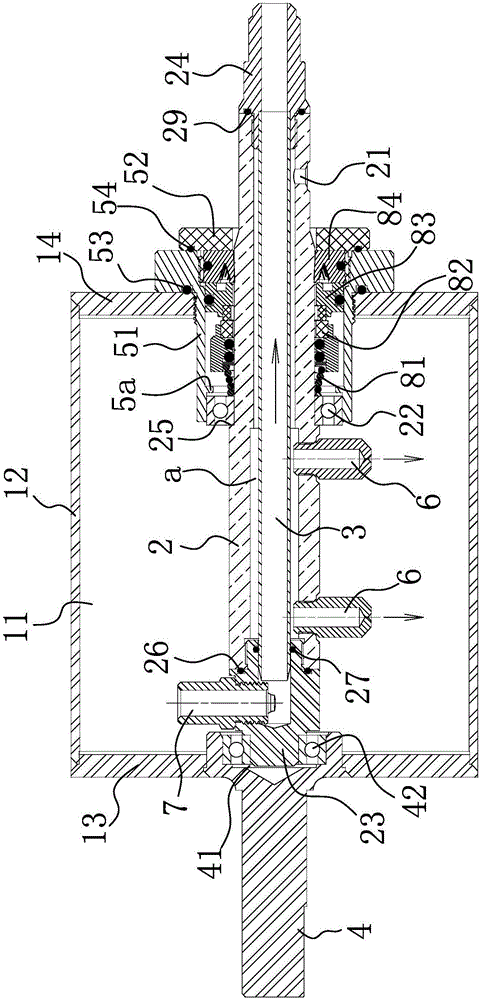

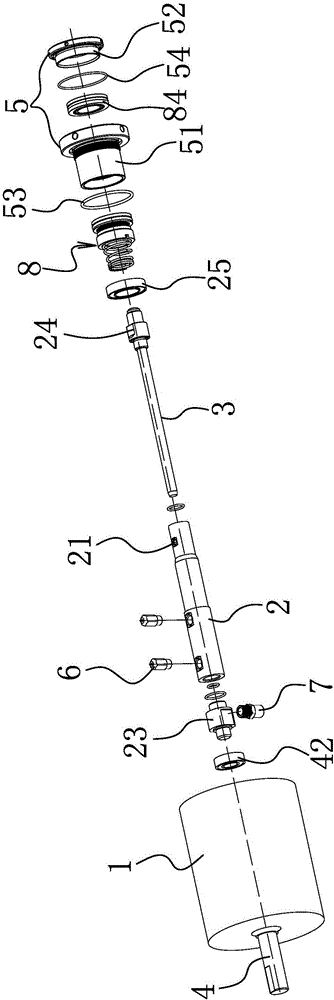

[0033] Such as Figure 1-2 As shown, the roller of this snowflake machine includes a roller body 1 with a cavity 11 inside, and the roller body 1 includes a roller ring 12, a left end cover 13 is provided at one end of the roller ring, and a right end cover 14 is provided at the other end of the roller ring. The axial center of the left end cover 13 is provided with a left mounting hole, and the axial center of the right end cover 14 is provided with a right mounting hole. The axis line of the left mounting hole coincides with the axis line of the right mounting hole. 13 joints are welded and connected, and the joints of the roller ring 12 and the right end cover 14 are welded and connected, that is, leakage at the joints is avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com