Excavator tamping device for groove

A technology for compaction devices and excavators, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of complex trench backfill compaction equipment, inability to guarantee quality, and high labor costs, so as to avoid quality failure and ensure compaction The effect of solidity requirements and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in more detail below with reference to the accompanying drawings and reference numerals, so that those skilled in the art can implement it after studying this specification. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

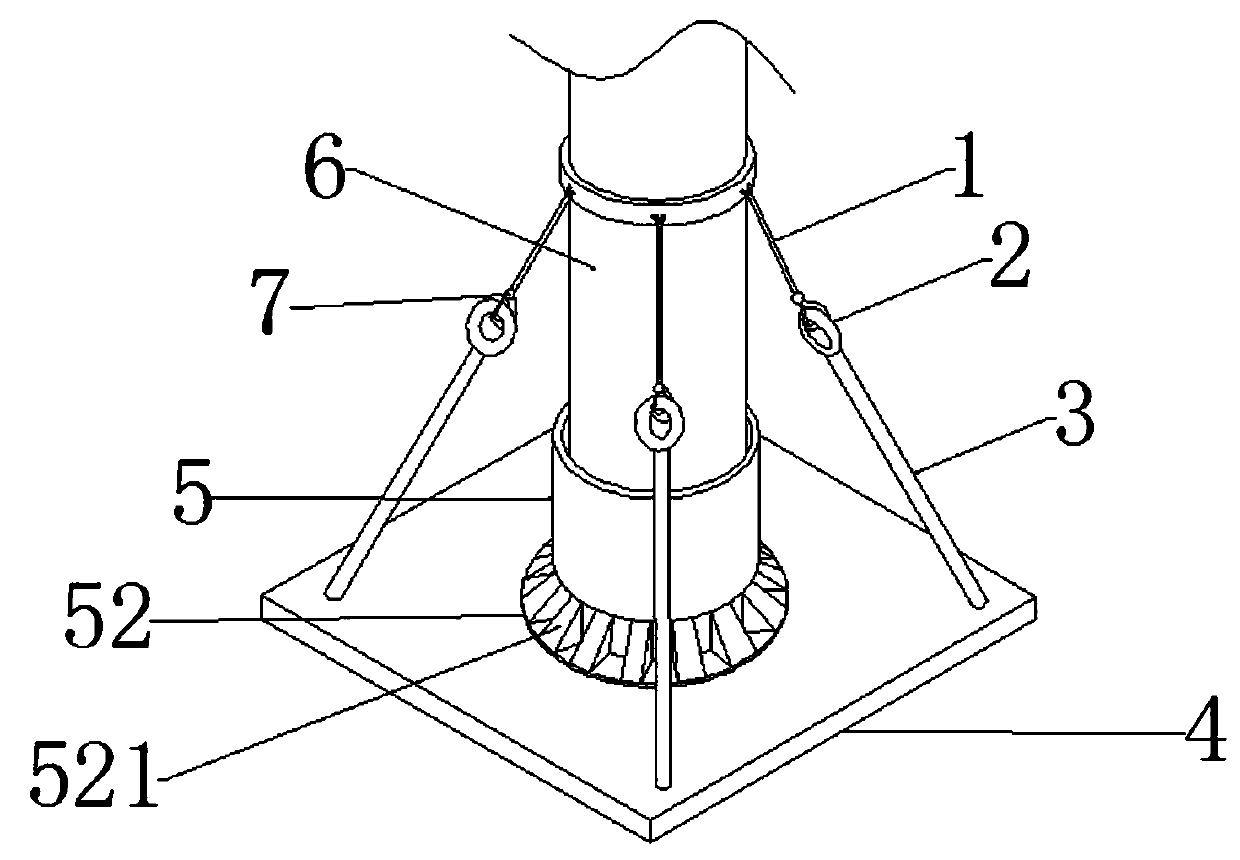

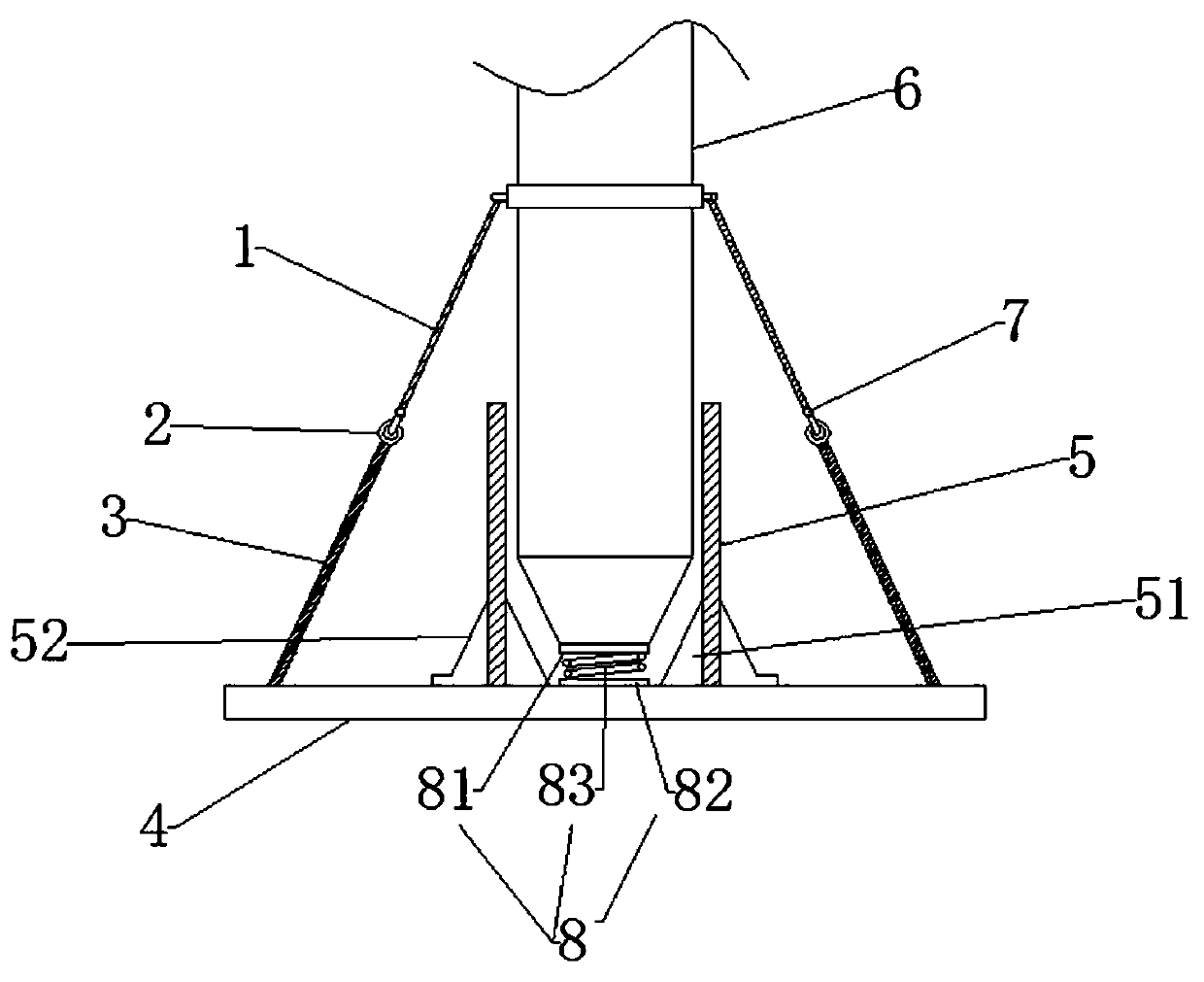

[0017] see Figure 1 to Figure 2 , an excavator tamping device for a trench, comprising a breaker hammer 6 and a tamping device; the upper part of the breaker 6 is connected to an excavator, and the upper part of the breaker is provided with three or more steel wire ropes 1; The tamper includes a steel plate 4, a steel pipe 6, and a steel bar 3, the steel pipe 6 is fixedly arranged at the center of the steel plate 4, the breaker hammer steel drill 6 is set inside the steel pipe 6, and the periphery of the steel plate 6 There are steel bars 3 that are fixedly connected with the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com