Double-way cross-shaped head transmission mechanism for reciprocating piston type compressor

A technology of reciprocating piston and transmission mechanism, applied in the field of compressors, can solve the problems of large size of components, high production cost, complicated structure of crankshaft, etc., and achieve the effect of improving reliability and reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

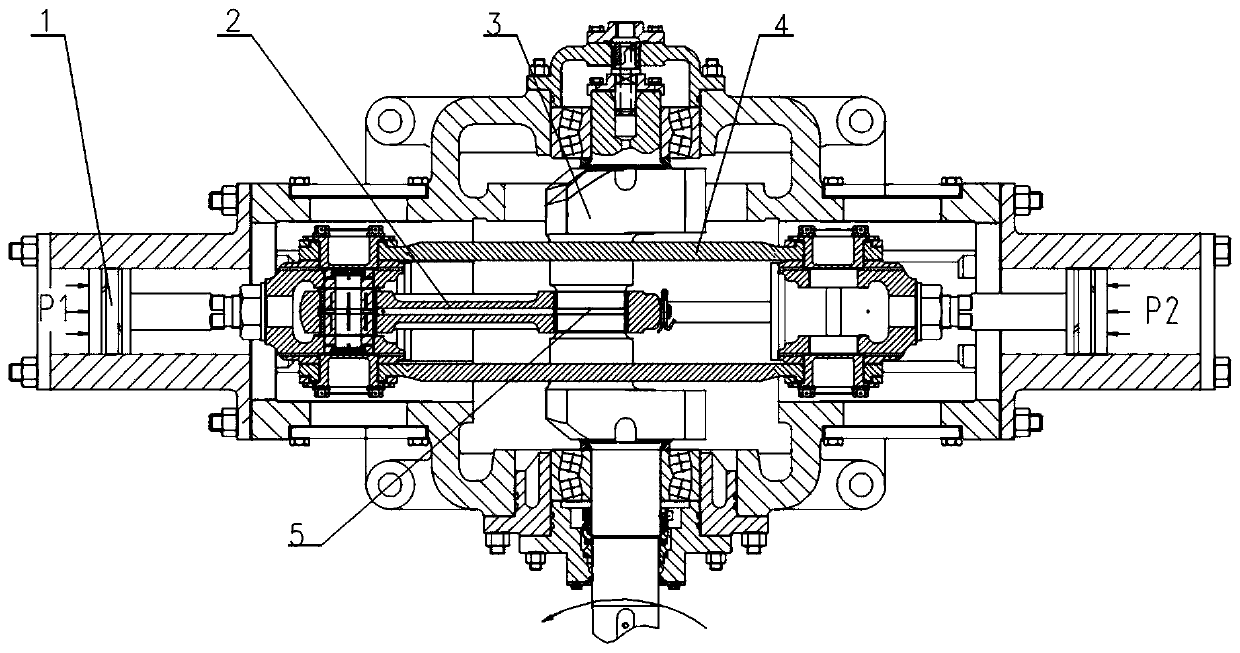

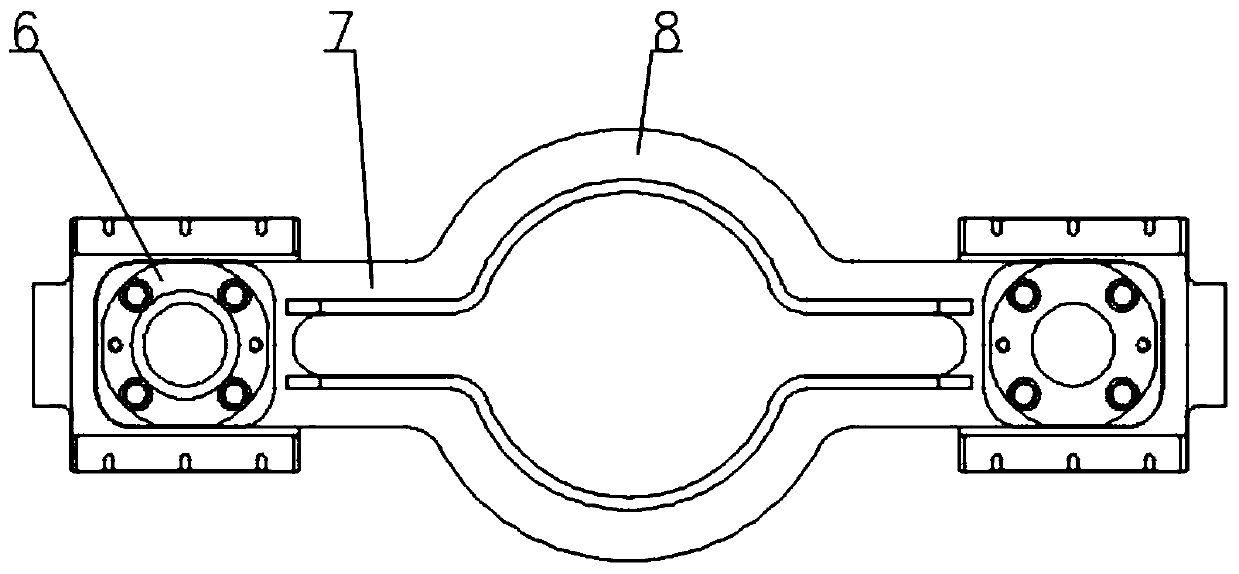

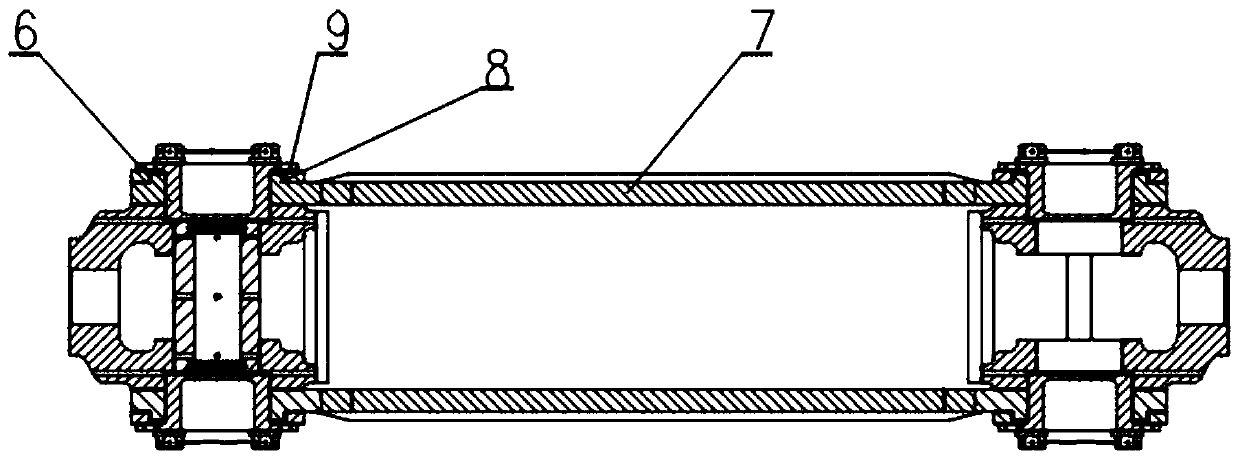

[0026] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0027] In this disclosure, unless stated otherwise, the used orientation words such as "up, down" are generally defined based on the orientation or positional relationship shown in the drawings, specifically refer to figure 1 The directions shown in the drawings are combined with the positional relationship of corresponding components in other drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

[0028] Such as figure 1 As shown, the bidirectional crosshead transmission mechanism for a reciprocating piston compressor according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com