V-shaped ball valve

A technology for ball valves and valve bodies, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc. It can solve the problems of easily damaged valve disc sealing surface and valve seat sealing surface, short service life, and easy adhesion. To achieve the effect of long service life, not easy to leak, and clean the sealing surface of the disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

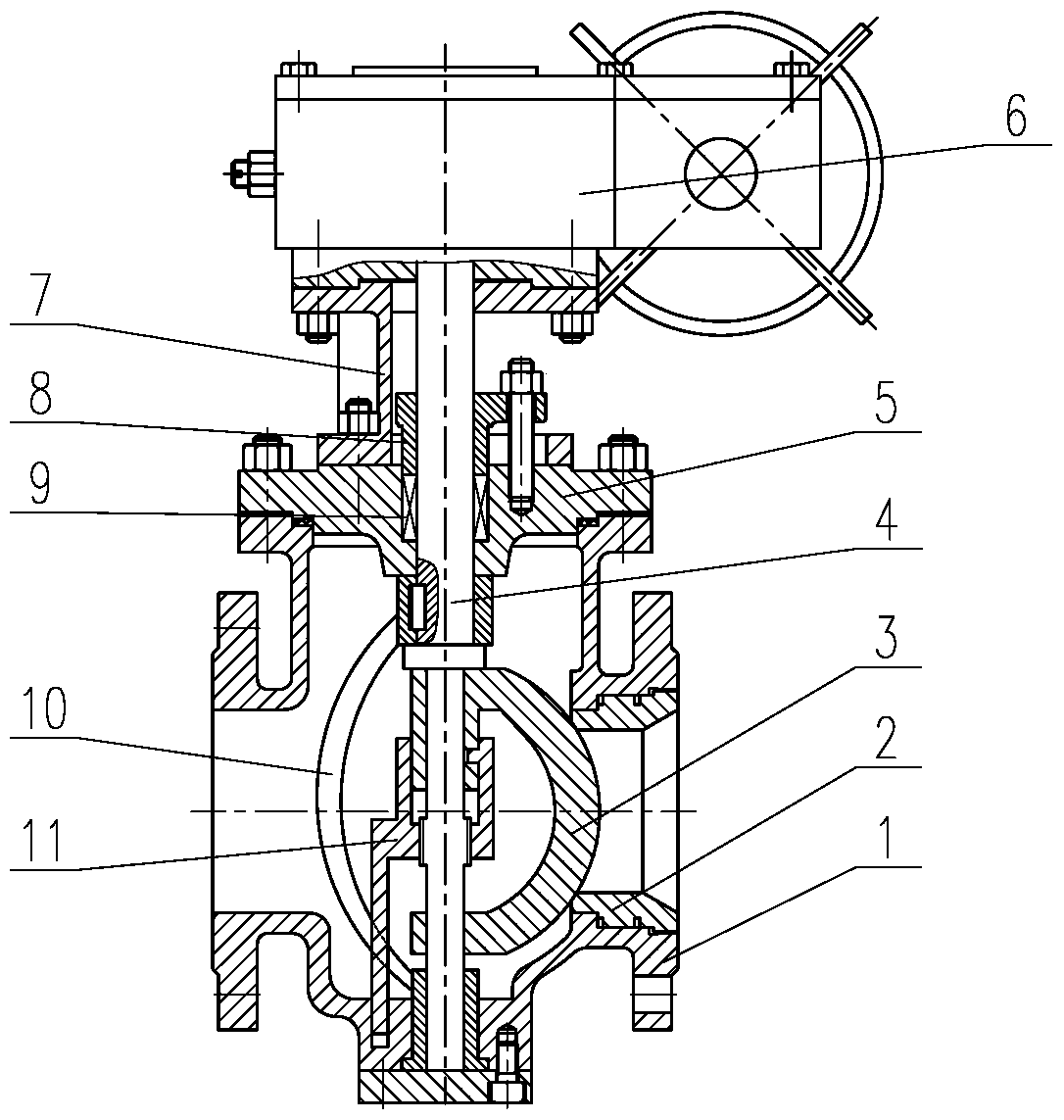

[0010] according to figure 1 It can be seen that this V-shaped ball valve includes: valve body 1, valve seat 2, V-shaped ball 3, valve cover 5, bracket 7, valve stem 4, packing 9, gland 8 and driving device 6, and the valve cover 5 is fixed Set on the upper end of the middle part of the valve body 1, the upper end of the bonnet 5 is provided with a stuffing groove, the gland 8 is installed above the stuffing groove, the stuffing 9 is fixedly installed in the stuffing groove by the gland 8, the lower end of the bracket 7 is fixedly connected with the bonnet 5, and the drive The device 6 is fixedly arranged on the upper end of the bracket 7, the V-shaped ball 3 is placed in the inner cavity of the valve body 1 as a whole, the outer surface of the V-shaped ball 3 is provided with a spherical disc sealing surface, the upper end of the valve stem 4 is connected with the driving device 6, and the valve stem 4 The lower end passes through the bracket 7, the gland 8, the packing 9, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com