Activated carbon flue gas purification system and its roller feeder discharge flow measurement method

A technology of flue gas purification system and feeder, which is applied in the field of flue gas purification, can solve problems such as inability to achieve accurate online measurement, and achieve the effect of accurate online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

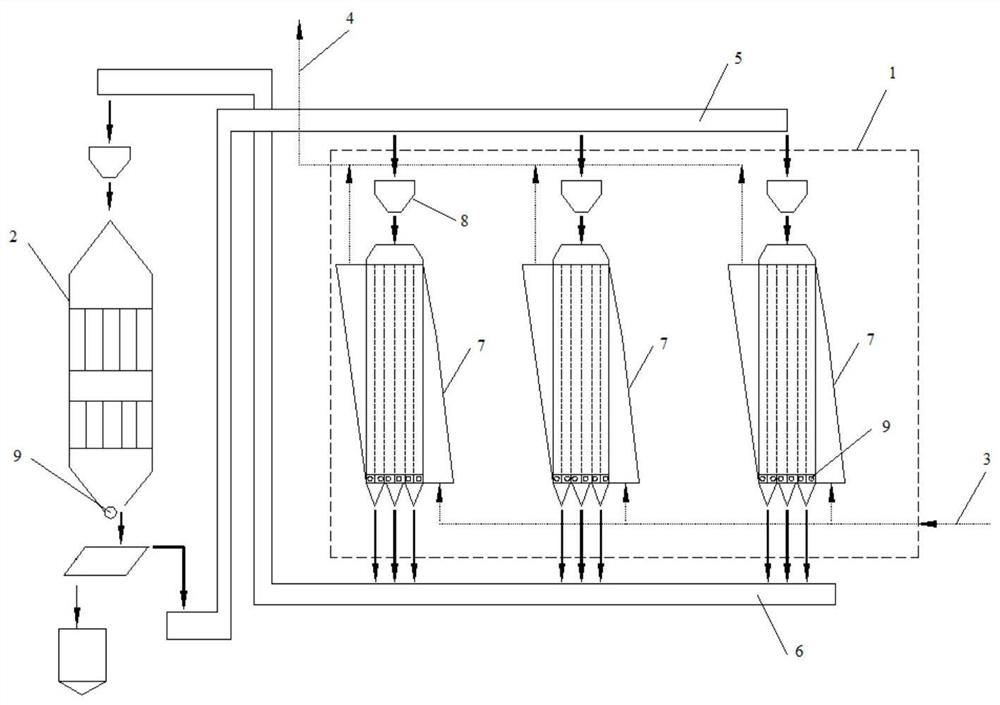

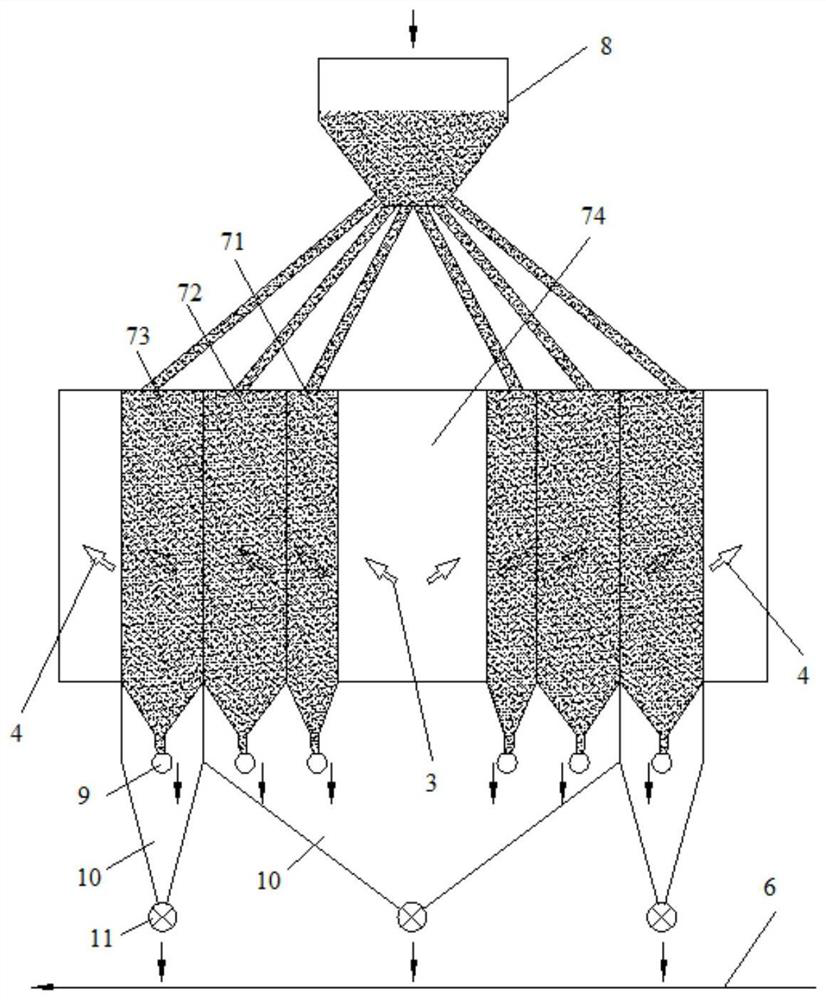

Embodiment Construction

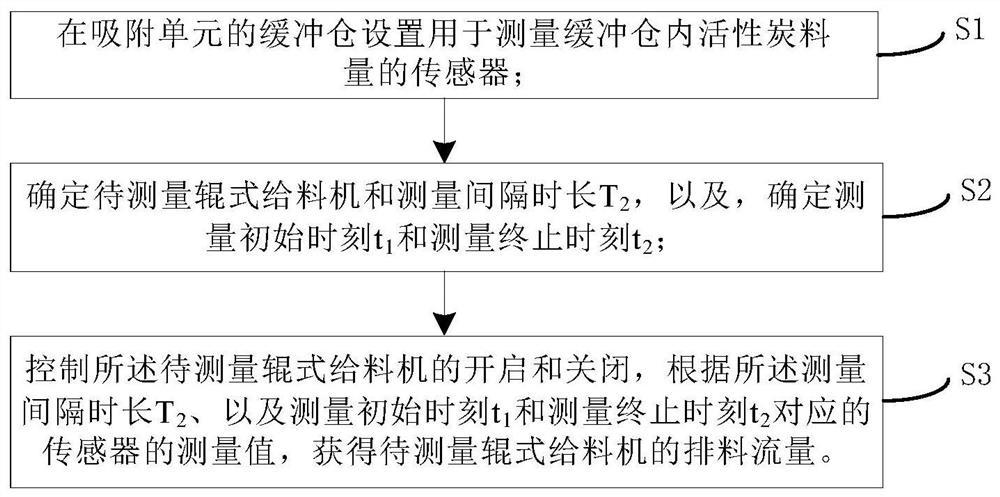

[0082] The measurement method provided in the embodiment of the present application is based on the structural characteristics of the activated carbon flue gas purification system. When the roller feeder is unloading, the amount of material discharged from the roller feeder is equal to the amount of material that the activated carbon in the buffer bin flows into the corresponding small chamber. Furthermore, each small chamber can be filled with activated carbon to give full play to the adsorption of activated carbon. Therefore, the reduced amount of material in the buffer bin can be used as the amount of material discharged by the roller feeder. According to this equivalence relationship, the technical solution of the present application controls the opening and closing of the roll feeder to be measured to obtain the change of the amount of activated carbon in the buffer bin under different conditions, thereby obtaining the discharge flow rate of the roll feeder. The technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com