U-shaped biconical fiber biofilm sensor and method of making and measuring

A biofilm and sensor technology, which is applied in U-shaped biconical fiber optic biofilm sensors and in the field of production and measurement, can solve the problems of inability to accurately measure the thickness of biofilm online, achieve good application prospects, unique structure, and improve the effect of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

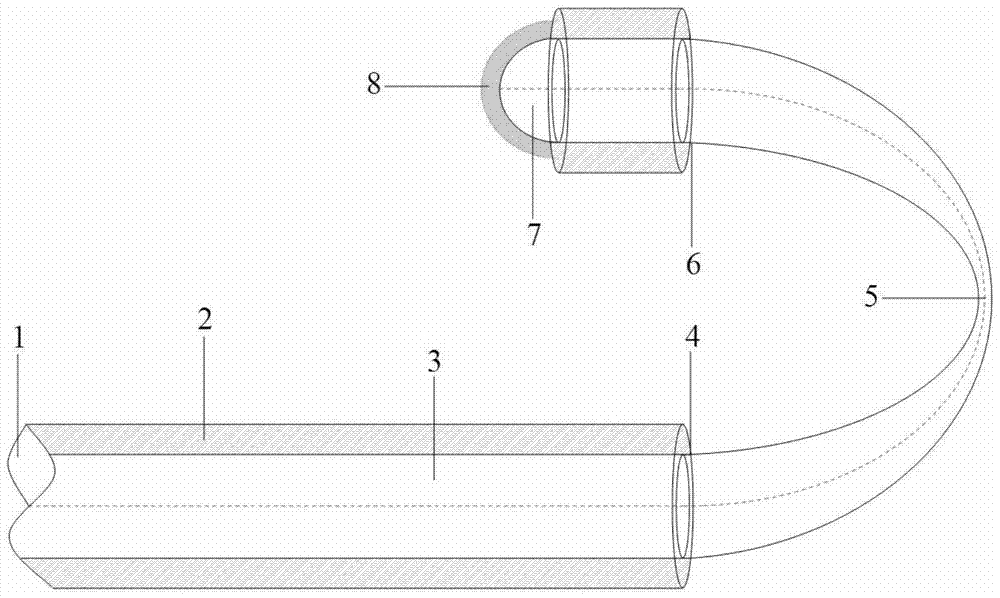

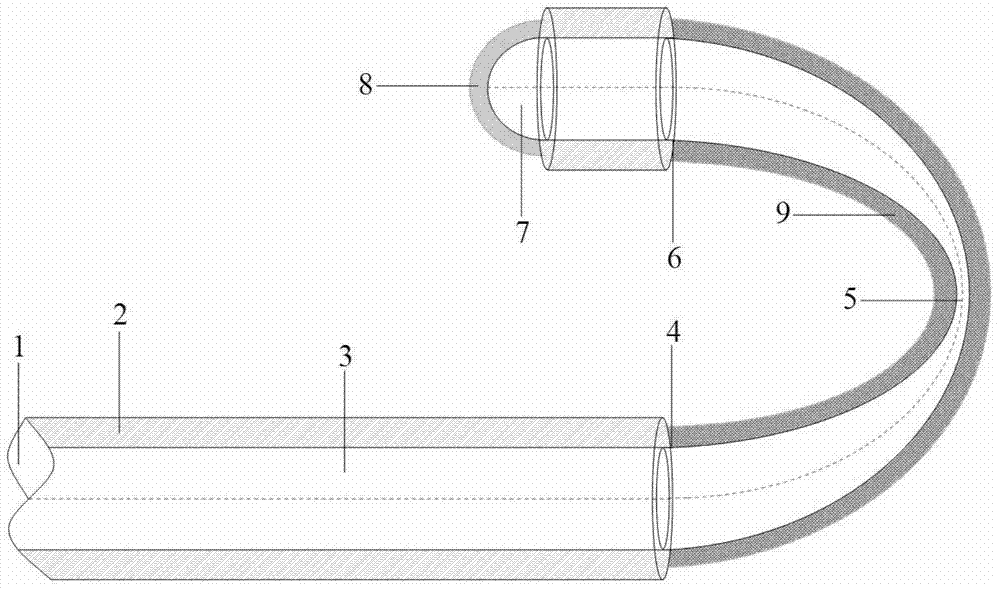

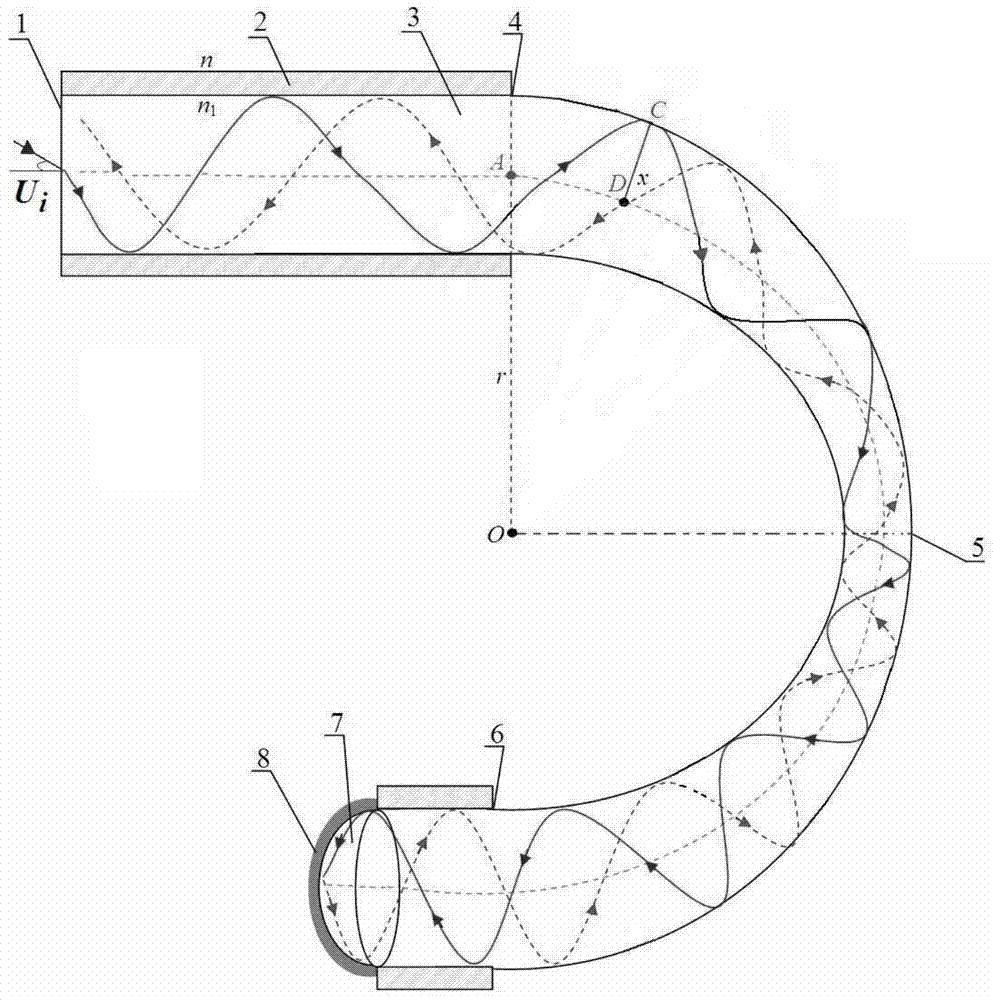

[0033] see Figure 1 to Figure 3 , a U-shaped biconical fiber optic biofilm sensor, including a measurement sensing arm and a reference sensing arm, the measurement sensing arm and the reference sensing arm are multimode optical fibers, including an optical fiber protective layer 2, a fiber core and an optical fiber cladding 3 , the middle region of the multimode optical fiber is the measurement area, the measurement areas of the measurement sensing arm and the reference sensing arm are all set as U-shaped, and the left and right arms of the U-shaped optical fiber have a taper that is large at the top and small at the bottom; The tail ends 7 of the measurement sensing arm and the reference sensing arm are all arranged in a hemispherical shape, and the surface of the hemispherical optical fiber cladding is coated with a metal film 8; the surface of the optical fiber in the measurement area of the reference sensing arm is coated with polyamide Imide silica hybrid membrane9.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com