Flexible film stretching and bending device

A technology of stretching, bending, and flexible film, which is applied in the direction of measuring device, using a stable bending force to test the strength and strength characteristics of materials, can solve the problems of inconvenience, single function of testing mold, and single optical testing of test samples, etc., to achieve The effect of convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

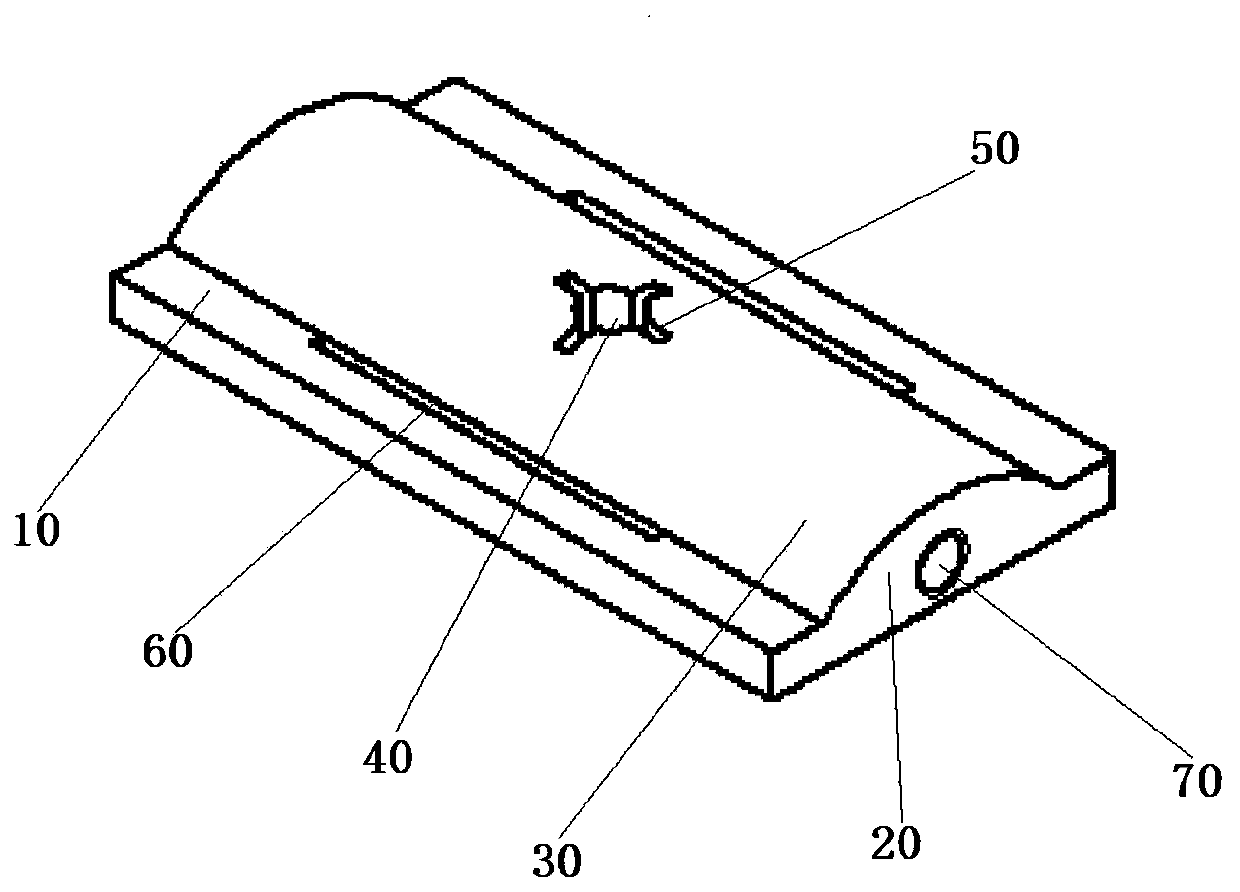

[0019] Please refer to figure 1 , a flexible film stretching and bending device, comprising a substrate 10, a surface of the substrate 10 is provided with a protrusion 20;

[0020] The surface of the protrusion 20 is a smooth arc surface 30, and the arc surface 30 of the protrusion 20 is provided with a light-through circular hole 40 penetrating through the substrate 10 at the top of the arc;

[0021] The arc surface 30 of the protrusion 20 is provided with a cross alignment groove 50 or a cross alignment line around the light hole 40 with the center of the light hole 40 as the center point. Card slots 60 are respectively provided on both sides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap