A distribution box with good heat dissipation performance for two-way linkage cranes

A heat dissipation performance, crane technology, applied in the direction of electrical components, substation/switch layout details, substation/switchgear cooling/ventilation, etc., can solve the problems of air pump inhaling a large amount of dust, difficult installation of electrical components, dustproof box and other problems , to increase the heat dissipation contact area, facilitate maintenance and cleaning, and ensure the effect of dustproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

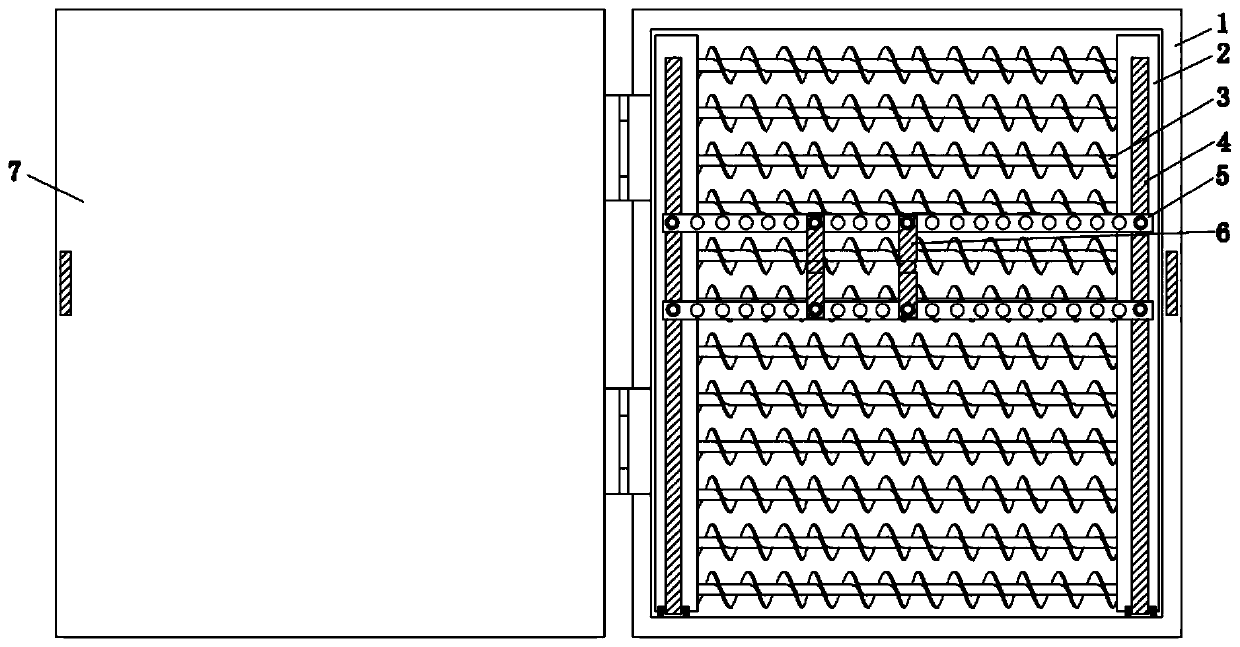

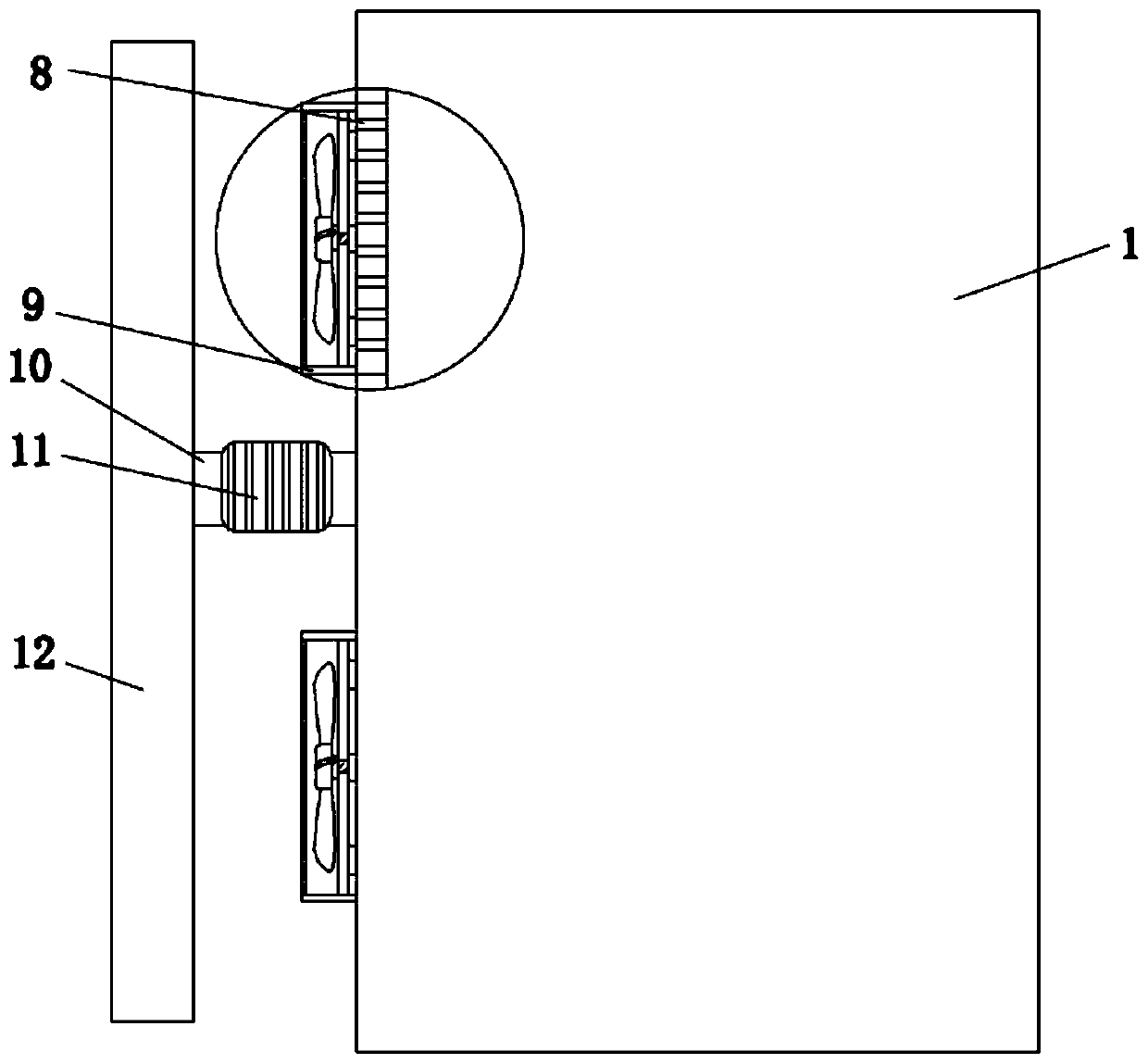

[0027] Such as Figure 1-2 As shown, it includes a box body 1, and vertically arranged inner flow pipes 2 are fixed on the left and right sides of the inner wall of the backboard of the box body 1, and a number of equidistantly distributed inner flow pipes 2 are provided on the side walls opposite to each other. The first installation hole, the two first installation holes where the internal flow pipes 2 on both sides are located on the same horizontal line are all screw-connected with the same heat-absorbing pipe 3, and are fixed on both sides of the outer wall of the backboard of the box body 1 with the inner Outflow tubes 12 arranged horizontally, and the side walls of the two outflow tubes 12 opposite to each other are provided with a number of equidistantly distributed second installation holes, and the outflow tubes 12 on both sides are located on the two second mounting holes on the same horizontal line. The installation holes are all screwed with the same cooling pipe ...

Embodiment 2

[0031] Embodiment 2 is a technical solution further optimized on the basis of Embodiment 1. Embodiment 2 is based on Embodiment 1. The bottom of the inner wall of the box body 1 is hinged with a pillar 4 arranged parallel to the inner flow pipe.

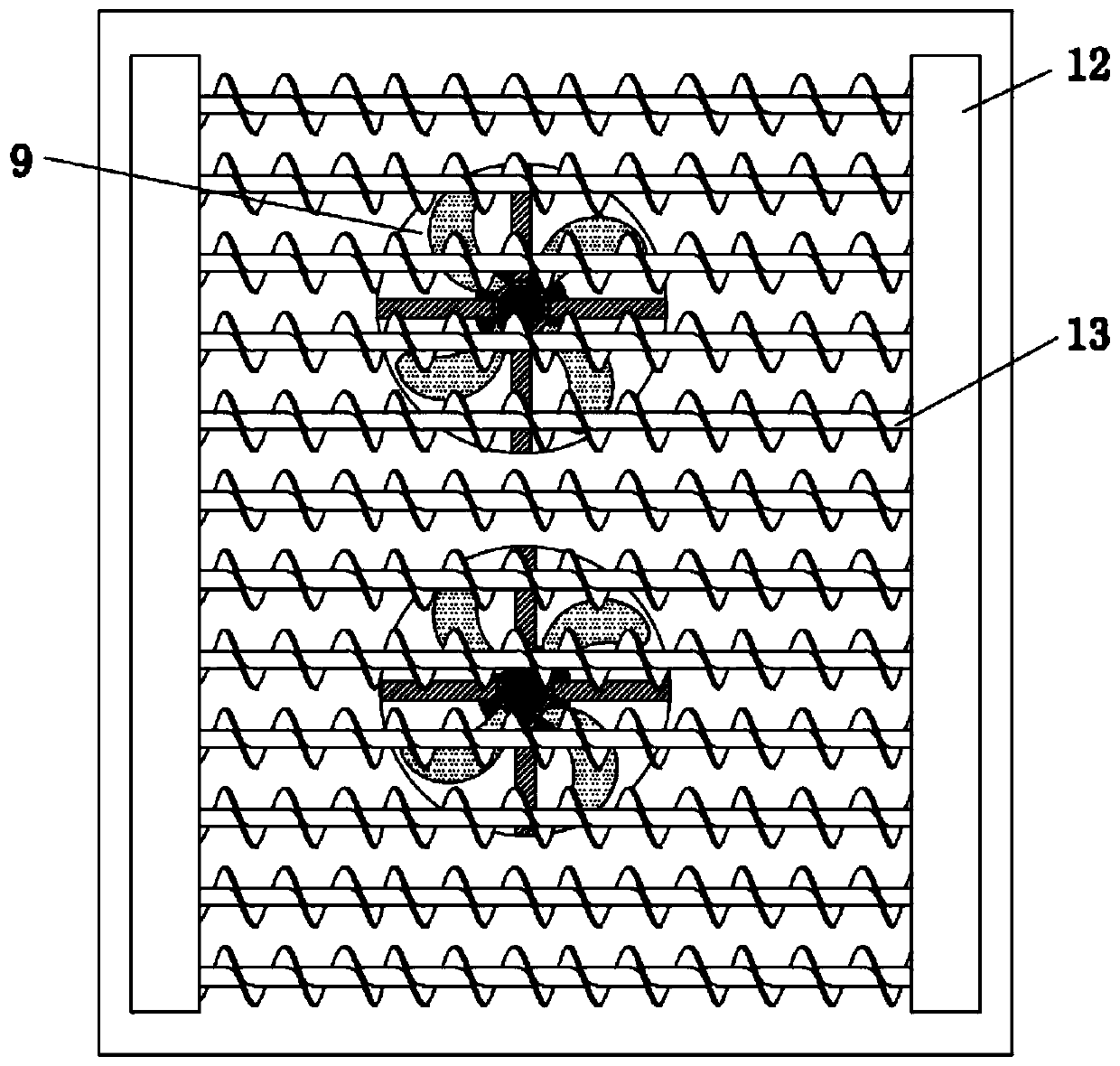

[0032] Such as Figure 5 As shown, the two inner flow pipes 2 and the two pillars 4 are connected by electric telescopic rods 14, and the two ends of the two electric telescopic rods 14 are respectively arranged opposite to the inner flow pipes 2 and the outer walls of the pillars 4. Hinged, the telescopic length of the electric telescopic rod 14 controls the distance between the pillar 4 and the inner flow pipe 2 .

[0033] Such as Figure 4 As shown, there are two horizontally arranged beam frames 5 slidingly connected between the two pillars 4, and several installation holes 17 are equidistantly distributed on the beam frames 5, and the vertical beam frames 6 are fixed between the two beam frames 5 by bolts. Install vertically w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap