Frame shaping device

A technology of shaping device and frame, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of poor calibration accuracy, slow movement, low sensitivity of oil cylinder, etc., and achieve the improvement of calibration accuracy and consistency, and continuous closed loop The effect of high correction and correction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

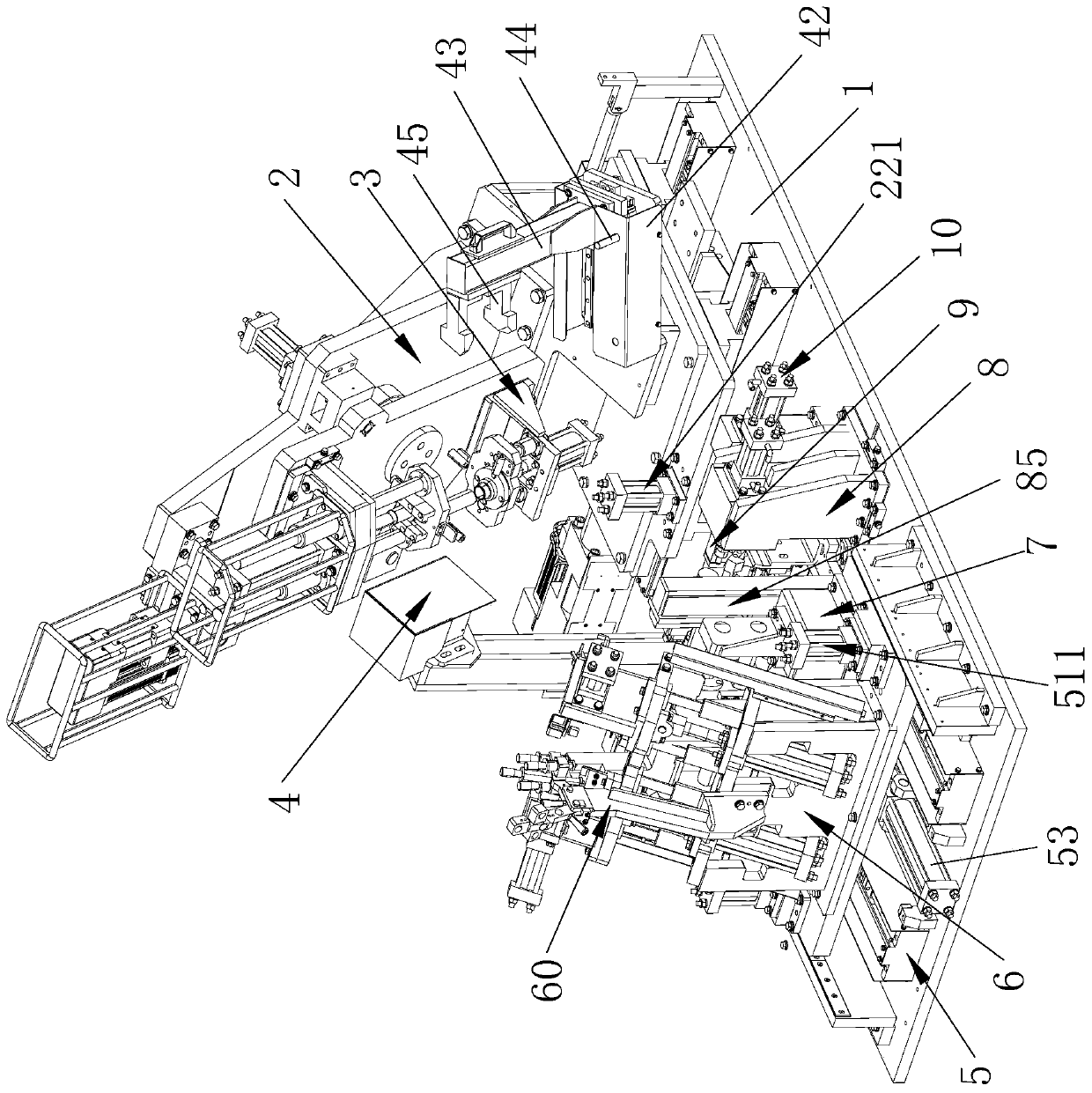

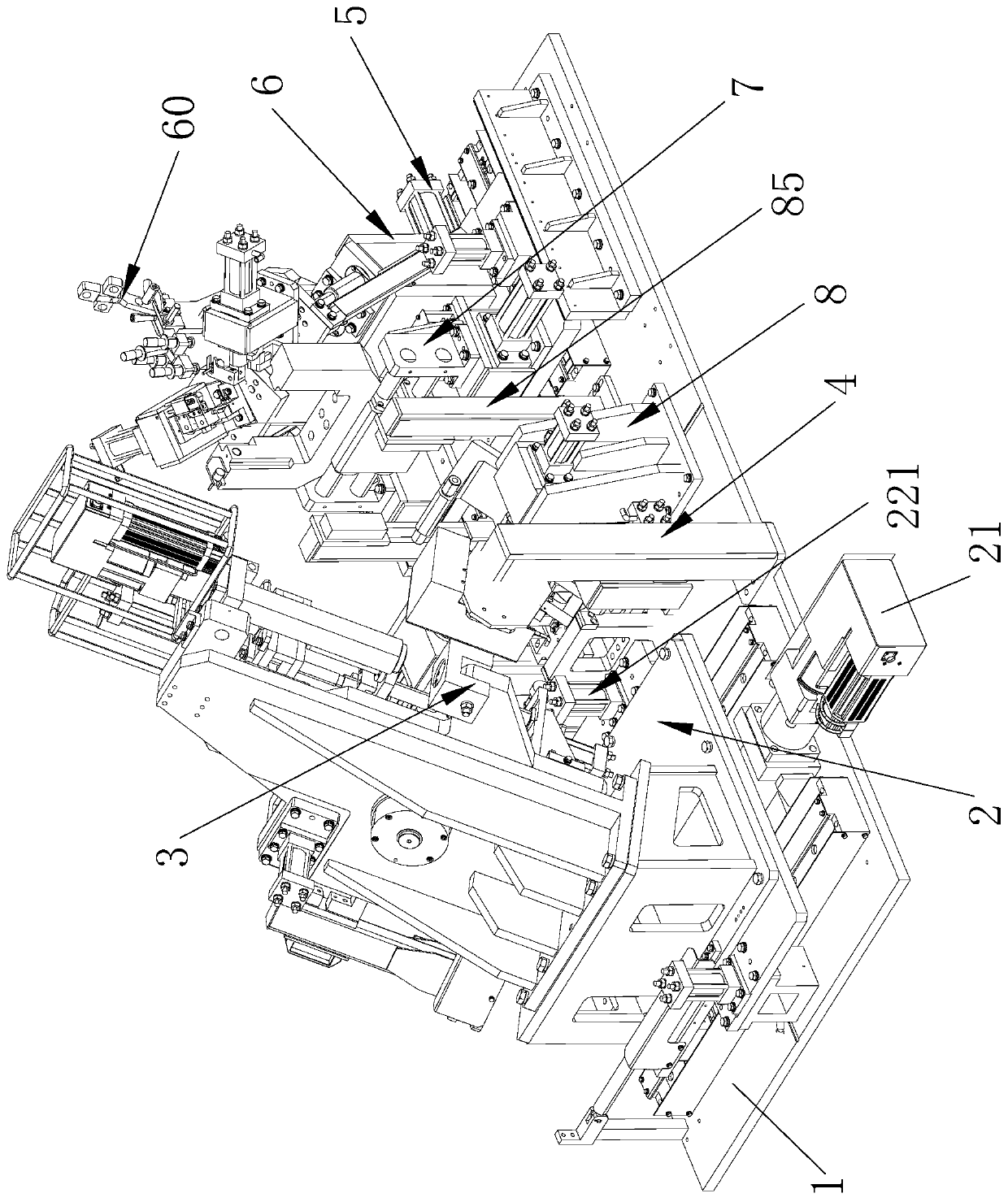

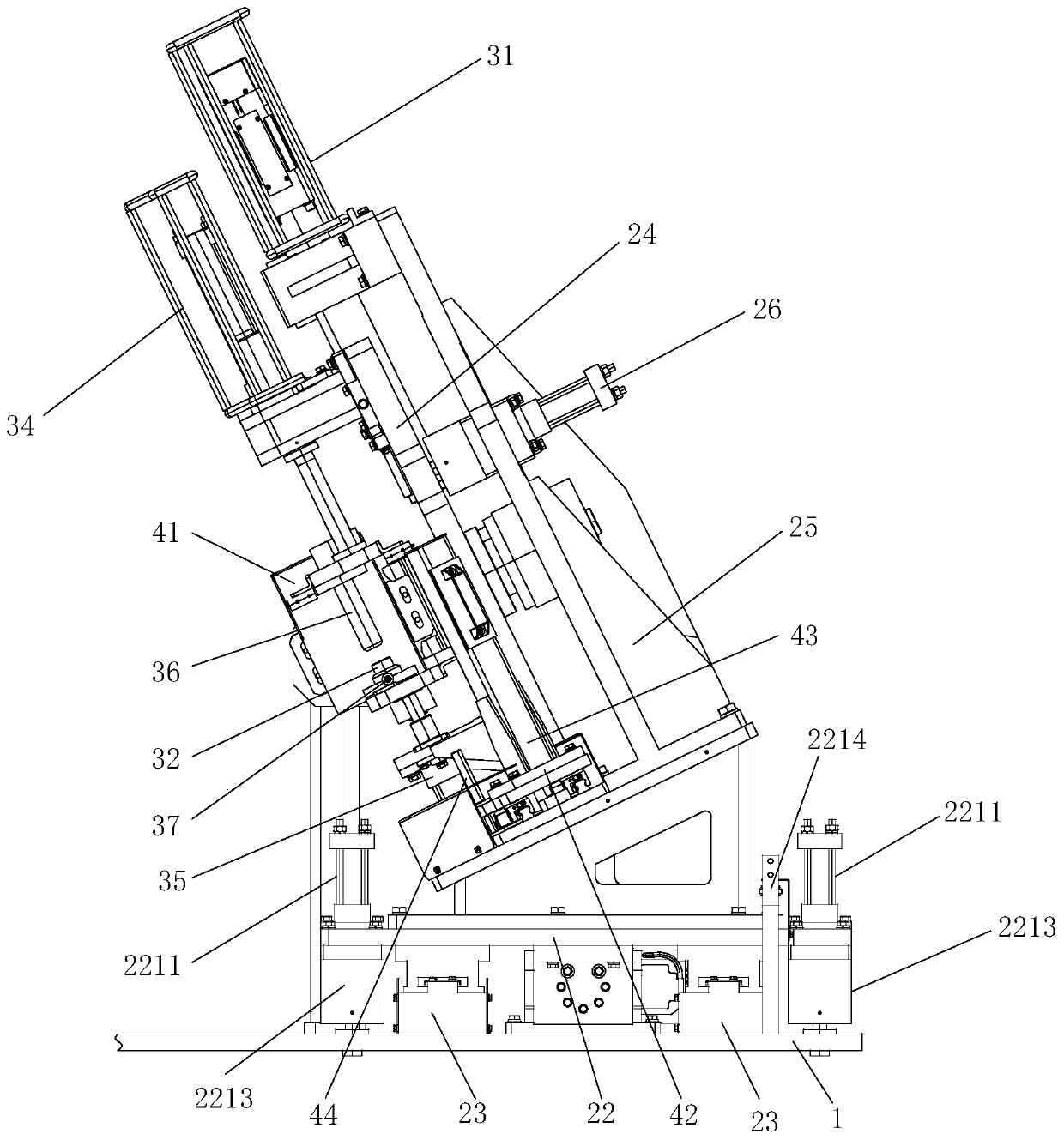

[0048] like Figure 1~14 As shown, a frame shaping device includes a base 1, and a frame positioning assembly, a frame front tube shaping assembly, a frame tail shaping assembly and a hydraulic system arranged on the base 1, and the frame positioning The assembly is located between the front tube shaping assembly and the tail shaping assembly of the frame, and the front tube shaping assembly includes the overall deviation correction mechanism 2 of the frame head, the front tube twist correction mechanism 3 and the front tube correction detection Agency 4,

[0049] The frame head overall deflection correction mechanism 2 includes a first servo electric cylinder 21, a front tube shaping pallet 22, a first guide rail 23, a torsion plate 24, a torsion base 25 and a torsion plate locking cylinder 26, The first guide rail 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com