A kind of slurry automatic preparation system and preparation method thereof

A preparation system and slurry technology, applied in chemical instruments and methods, clay preparation devices, control devices, etc., can solve the problems of difficult sediment cleaning, small output of the preparation system, poor slurry uniformity, etc., to improve continuity and pulping output , Realize the effect of automation and refinement, easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

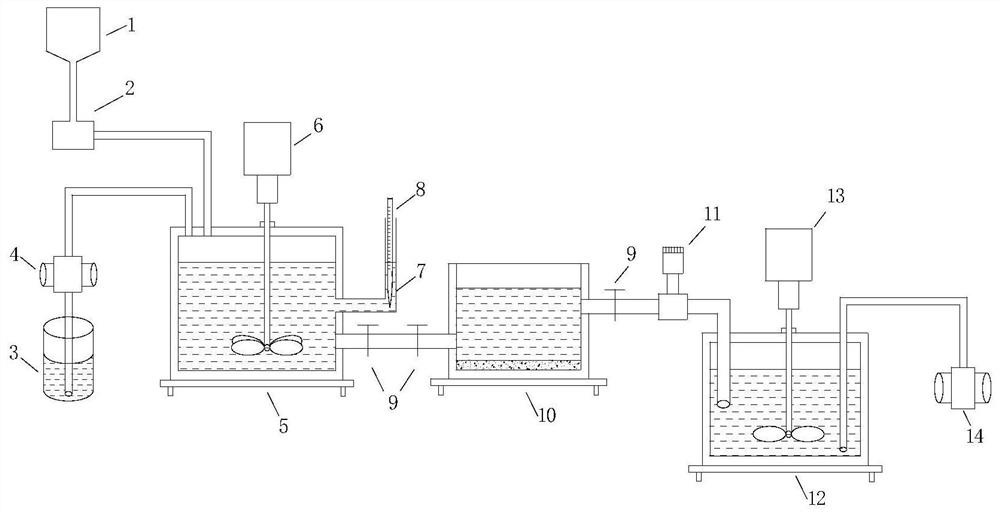

[0034] In one or more embodiments, a method for implementing a slurry preparation system is disclosed, comprising the following steps:

[0035] A. According to the set ratio, use the water pump 4 to pump a certain quality of water into the first-stage mixing tank 5, then start the automatic feeding platform 2, and stir synchronously when adding slurry materials.

[0036] B. Observe the value of the density meter 8 in the upper U-shaped pipe 7 of the primary mixing tank 5, and close the automatic feeding platform 2 when the slurry density reaches the design value.

[0037] C. After the slurry is stirred in the primary stirring tank 5 for 20 minutes, open the one-way valve 9 to allow the slurry to flow through the sedimentation tank 10 and the flow meter 11, and then flow into the secondary stirring tank 12.

[0038] D. When the slurry flows into the secondary mixing tank 12, it can be stirred, and after all the slurry flows in, each one-way valve 9 is closed, and now the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com