Plied oilless nylon 6 DTY (draw textured yarn), production technique thereof and draw-texturing machine to implement production technique

A production process and technology of nylon, which is applied in the field of nylon DTY texturing, can solve the problems of bad influence of fabric dyeing, uneven fabric dyeing, poor color fastness, etc., and achieve the goals of reducing printing and dyeing wastewater, excellent physical properties, and saving equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

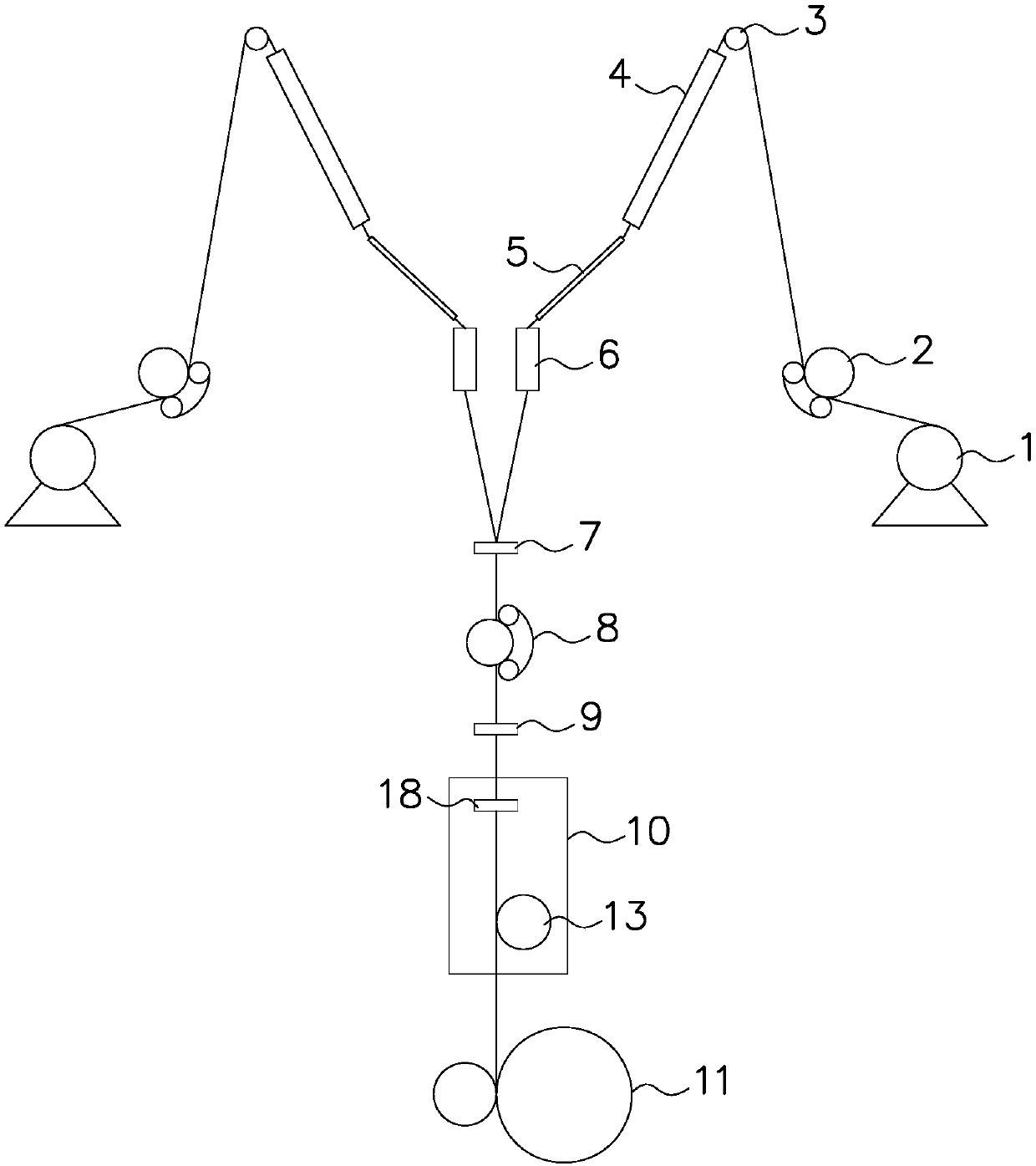

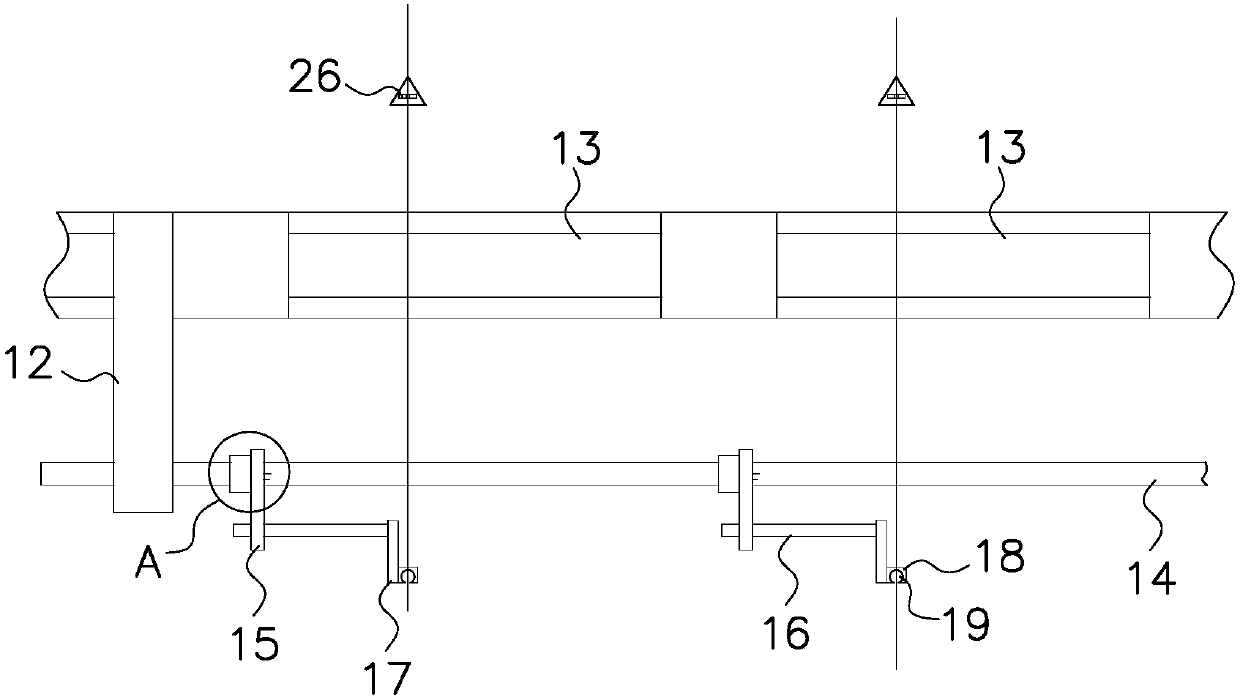

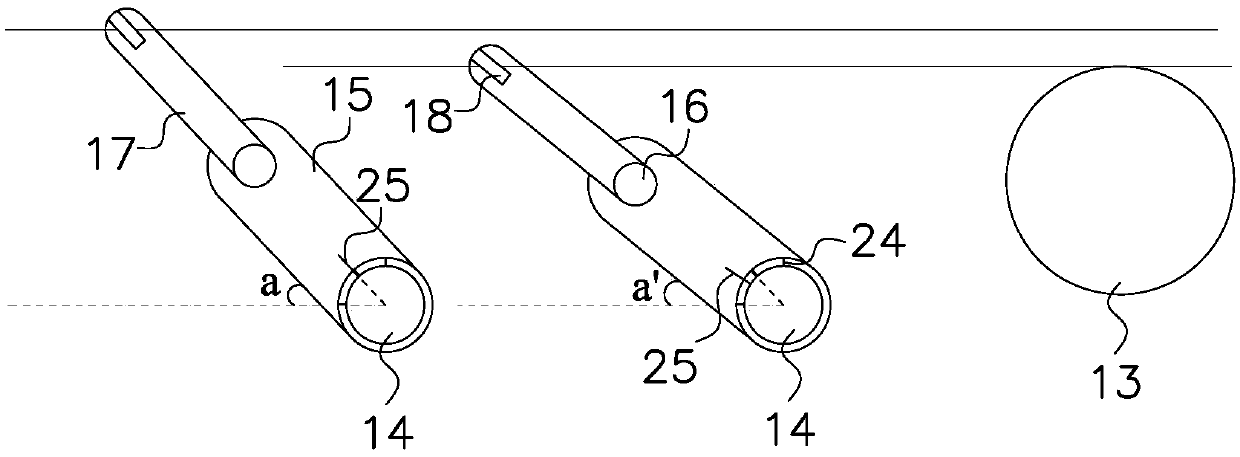

[0042] This embodiment introduces the production process of the present invention by taking 78dtex / 48f joint stock oil-free PA6DTY as an example.

[0043] The main equipment used in this production process is the joint texturing machine. For the structural diagram of the equipment, please refer to figure 1 .

[0044] Such as figure 1 Shown, under the assistance of this joint texturing machine, the production technology of the present embodiment comprises:

[0045](1) Two strands of raw silk are respectively drawn from the raw silk frame 1, and each is fed into the hot box 4 by a roller 2. The top of the hot box 4 is provided with a twist stopper 3, and the raw silk first passes through the twist stopper 3 and then enters the hot box. Box 4: In the hot box 4, the raw yarn is heated to 170°C and stretched under the action of the second roller 8. The surface line speed of the second roller 8 is 700m / min, the draw ratio is 1.265, and the D / Y ratio is 1.9;

[0046] (2) After be...

Embodiment 78

[0061] Adopt the equipment identical with embodiment 1 to carry out texturing, the production technology of present embodiment 78dtex / 48f joint stock oil-free PA6DTY comprises:

[0062] (1) Two strands of raw silk are respectively drawn from the raw silk frame 1, and each is fed into the hot box 4 by a roller 2. The top of the hot box 4 is provided with a twist stopper 3, and the raw silk first passes through the twist stopper 3 and then enters the hot box. Box 4: In the hot box 4, the raw yarn is heated to 170°C and stretched under the action of the second roller 8. The surface line speed of the second roller 8 is 700m / min, the draw ratio is 1.250, and the D / Y ratio is 1.7;

[0063] (2) After being cooled to 80 DEG C by the cooling plate 5, the two tows heated and stretched enter a false twister 6 respectively for false twist processing;

[0064] The rotating speeds of two false twisters 6 are the same but the twist direction is opposite, thereby obtaining two strands of tow...

Embodiment 3

[0070] Adopt the equipment identical with embodiment 1 to carry out texturing, the production technology of present embodiment 78dtex / 48f joint stock oil-free PA6DTY comprises:

[0071] (1) Two strands of raw silk are respectively drawn from the raw silk frame 1, and each is fed into the hot box 4 by a roller 2. The top of the hot box 4 is provided with a twist stopper 3, and the raw silk first passes through the twist stopper 3 and then enters the hot box. Box 4: In the hot box 4, the raw yarn is heated to 170°C and stretched under the action of the second roller 8. The surface line speed of the second roller 8 is 700m / min, the draw ratio is 1.280, and the D / Y ratio is 1.8;

[0072] (2) After being cooled to 80 DEG C by the cooling plate 5, the two tows heated and stretched enter a false twister 6 respectively for false twist processing;

[0073] The rotating speeds of two false twisters 6 are the same but the twist direction is opposite, thereby obtaining two strands of tow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com