Roofing structure for assembling house

A technology for housing and supporting frame, applied in truss structure, building structure, joists, etc., can solve the problems of troublesome construction and installation, troublesome disassembly, complicated operation, etc., to reduce the construction procedure and workload, save time and The effect of short labor costs, production and installation cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

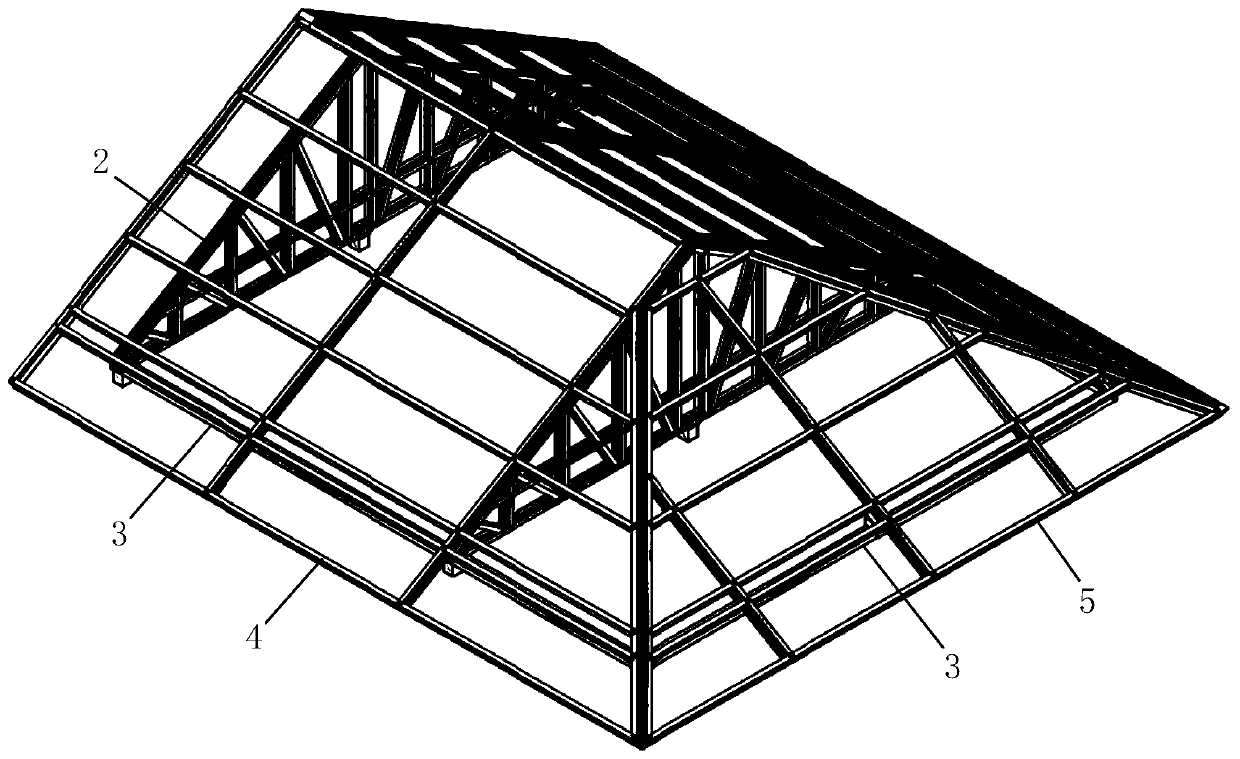

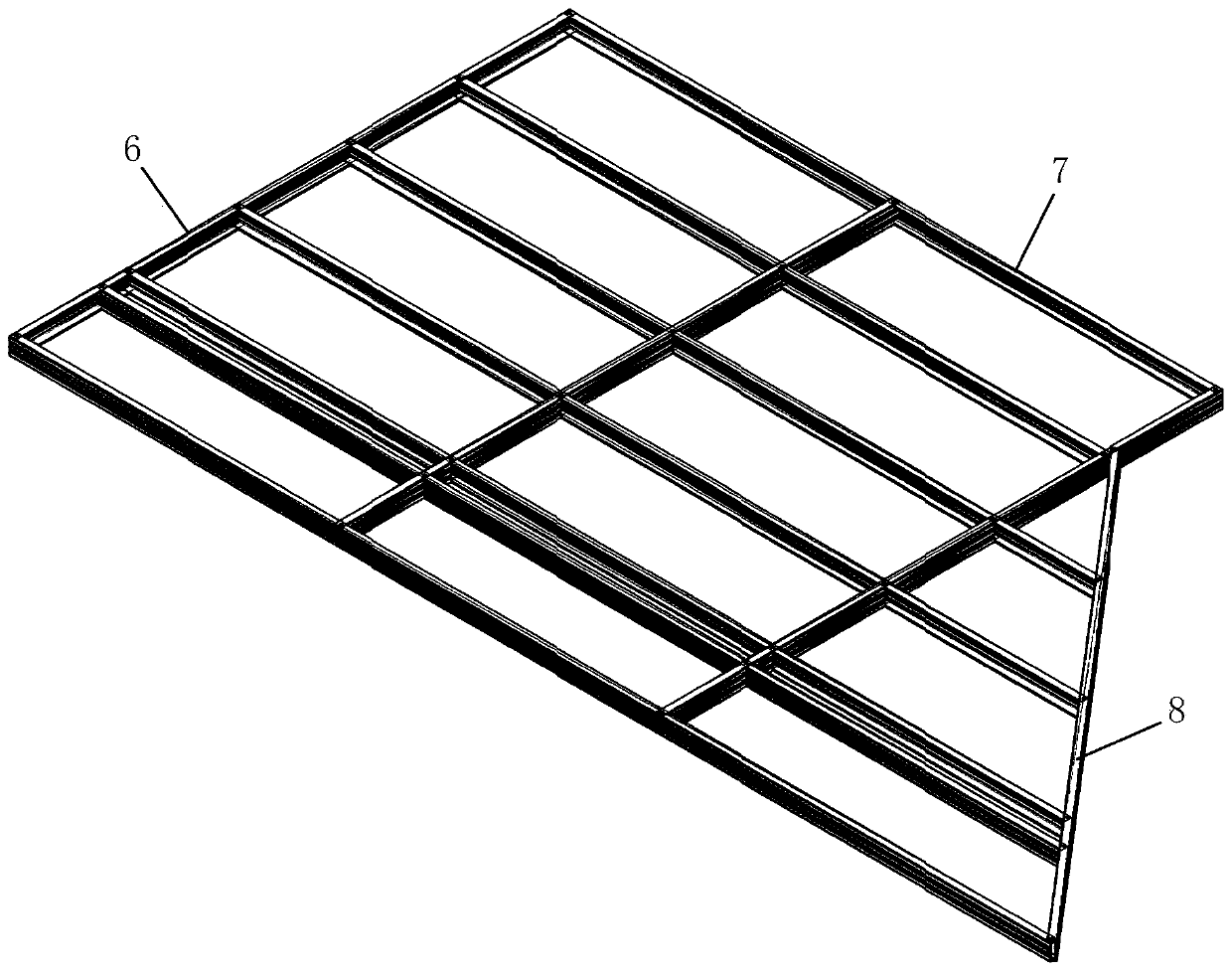

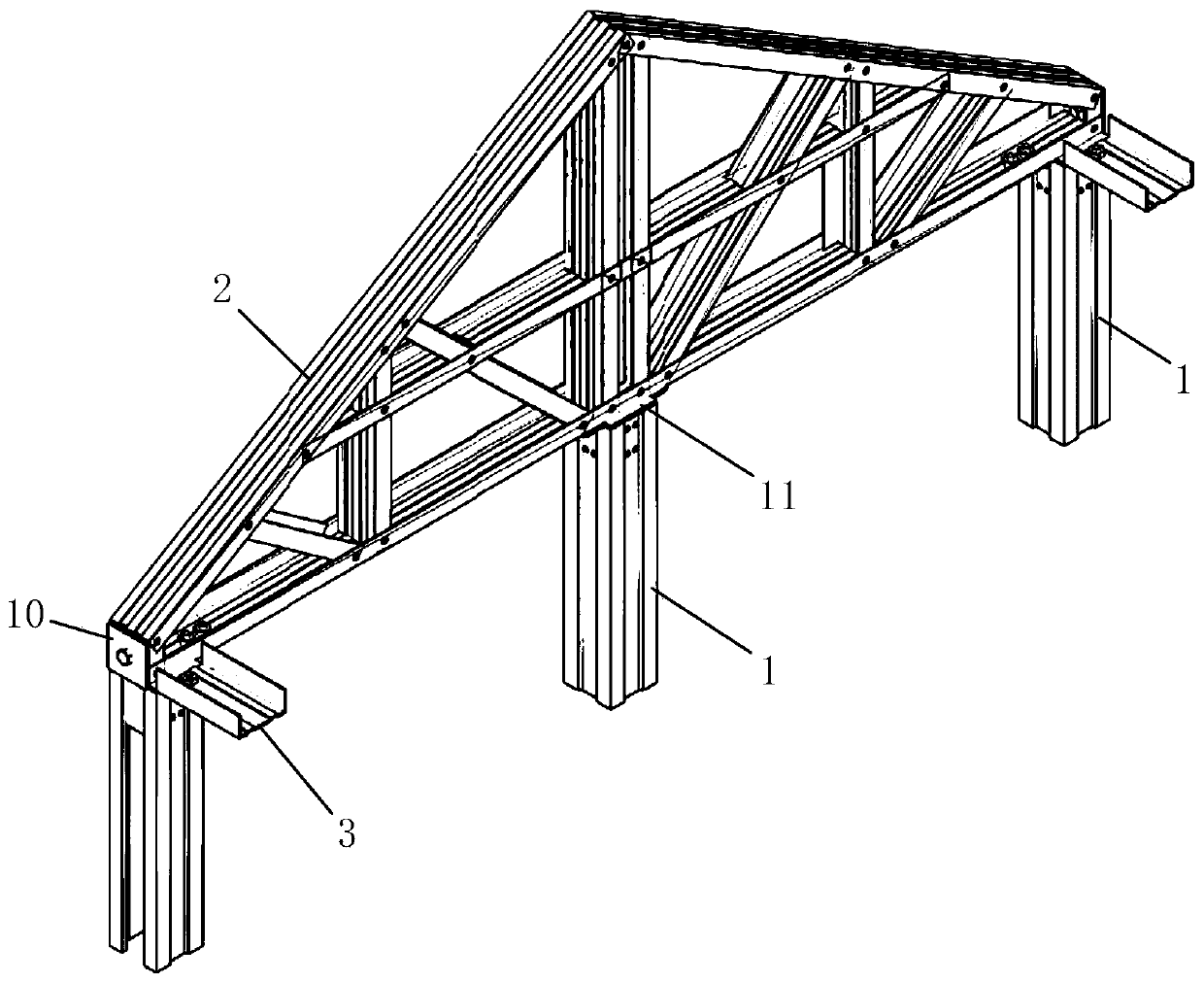

[0023] In this example, refer to Figure 1-Figure 7 , the roof structure for assembling the house includes a roof support frame 2 (such as a triangle), a ring beam 3 and a main truss 4 for forming a roof part, the support frame 2 is installed on the column 1 of the house, and the main truss 4 includes longitudinal beams 6 and cross beams 7, and the main truss 4 is installed on the support frame 2 and the ring beam 2; end connectors are installed on the top of the column at the outer position (that is, the column used to match the two ends of the support frame) 10, and the top of the column at the middle position (that is, the column used to match the middle position of the support frame) is equipped with a support frame intermediate connector 11, and the two ends of the support frame 2 are respectively connected to the column 13 at the outer position through the end connector 10. The connection is fixed, and the middle of the support frame 2 is connected and fixed with the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com