Assembled house structure

A prefabricated and housing technology, which is applied in the direction of building structure and construction, can solve the problems of troublesome construction and installation process, troublesome disassembly, and small supporting area, so as to reduce construction procedures and workload, save time and labor costs, The effect of short production and installation cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

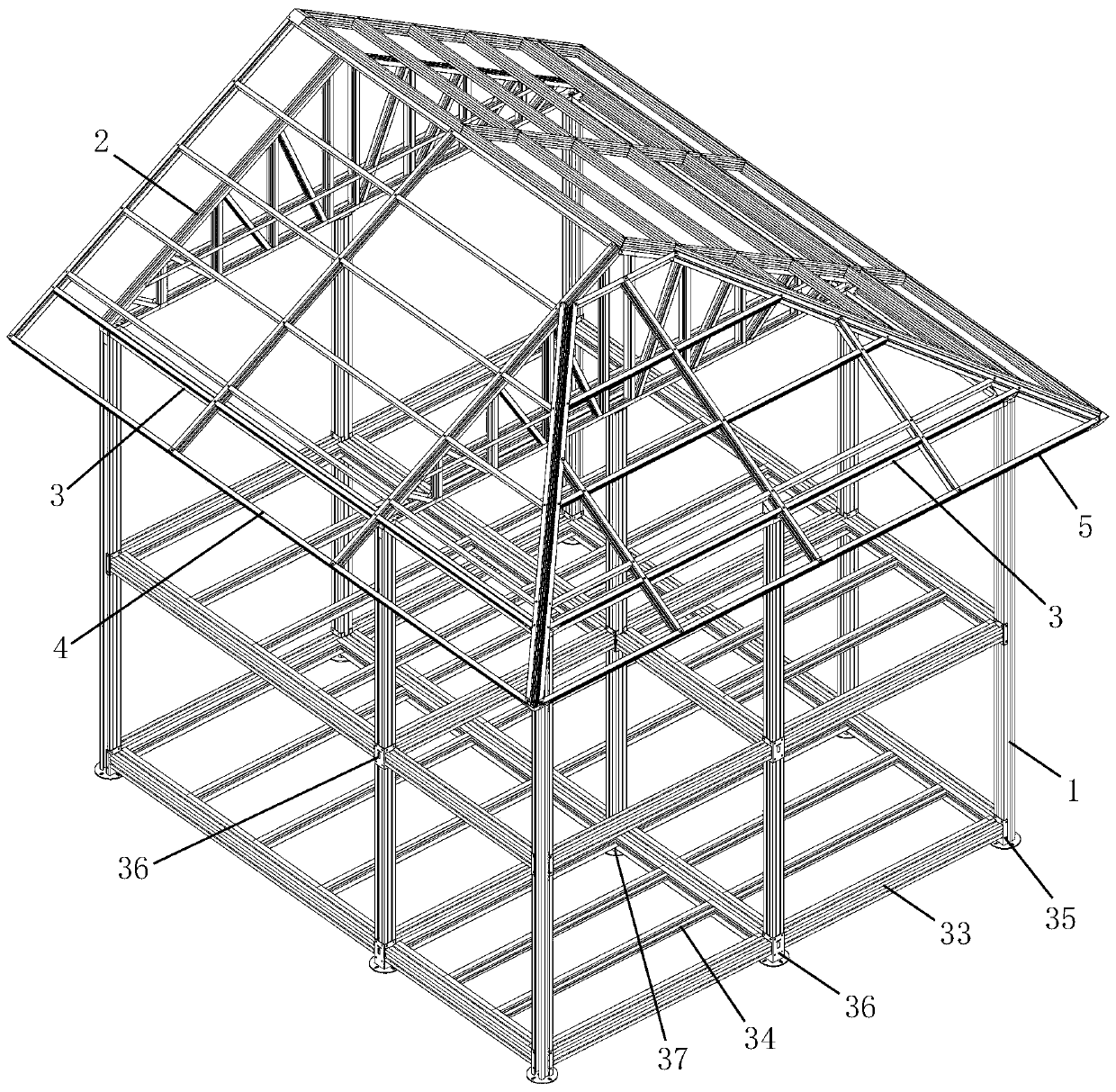

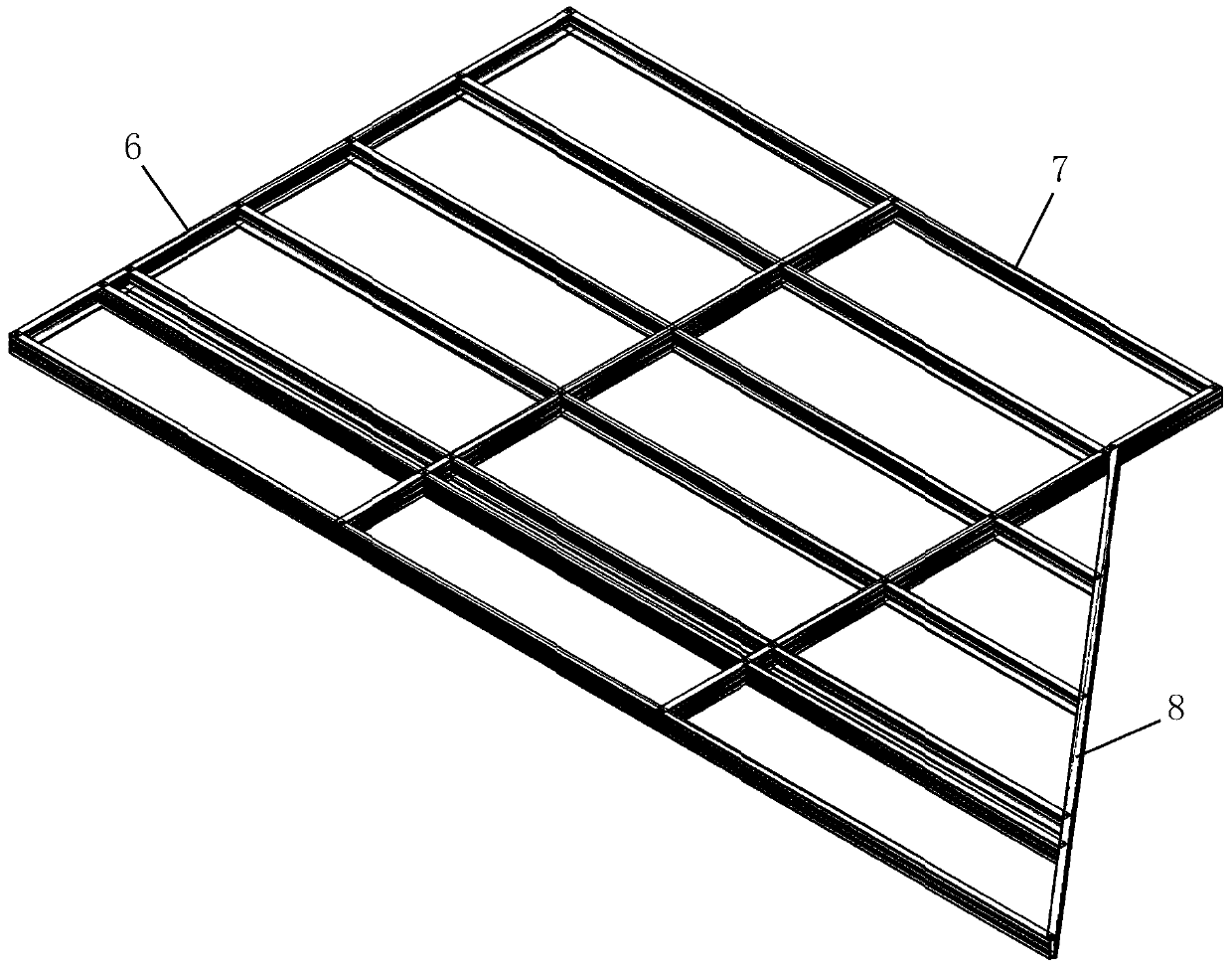

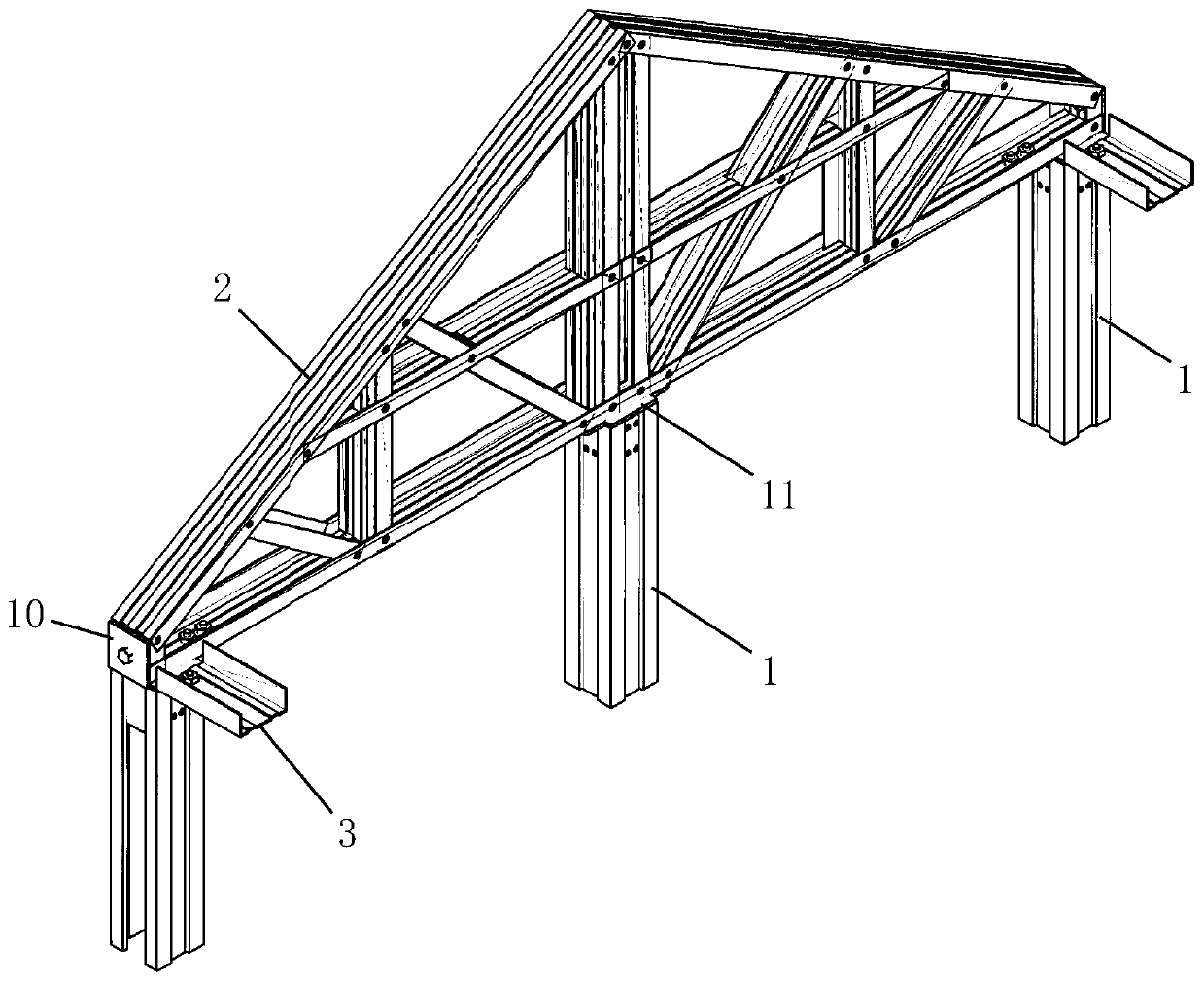

[0033] In this example, refer to Figure 1-Figure 14 , the prefabricated house structure includes a column 1, a ground steel frame 34, a roof support frame 2 (such as a triangle), a ring beam 3 and a main truss 4 for forming a roof part, and the support frame 2 is installed on the column 1 , the column 1 is fixed on the ground; the main truss 4 includes a longitudinal bar 6 and a beam 7, the main truss 4 is installed on the support frame 2 and the ring beam 2, and at least the lower and middle positions between the columns 1 are connected by connecting pieces Crossbeam 33, ground steel frame 34 is installed between the crossbeam 33 that is positioned at column 1 lower position; End connector 10 is installed on the column that is positioned at outside position (is exactly the column that is used for pairing with support frame two ends) top, and is positioned at A support frame intermediate connector 11 is installed on the top of the column in the middle position (the column tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com